Chalcogenide optical element with electromagnetic shielding performance and preparation method thereof

A technology for optical components and electromagnetic shielding, applied in optical components, optics, instruments, etc., can solve the problems of increasing the technical difficulty of chalcogenide glass windows and optical components, damage to the optical surface of chalcogenide glass, and difficult process control, etc., to achieve electromagnetic Good shielding performance, increased infrared light transmittance, strong electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

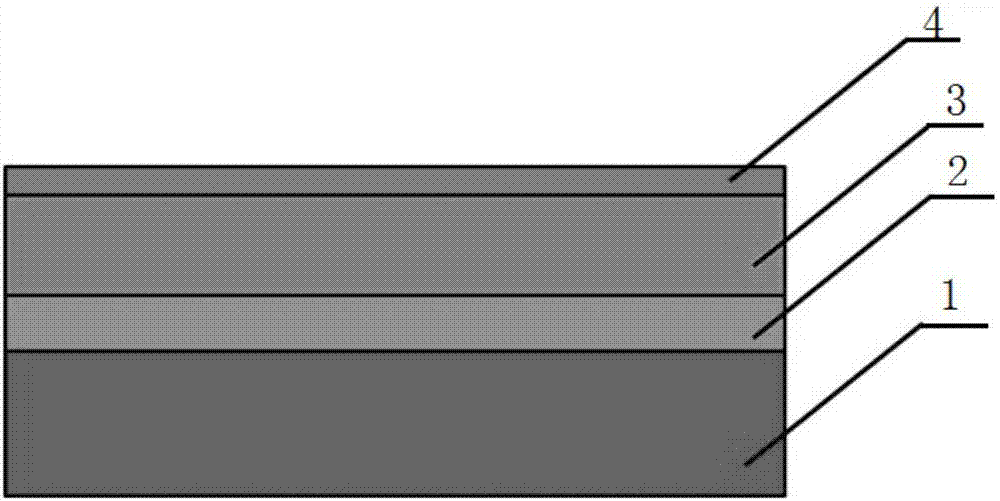

[0032] One embodiment of the present invention proposes a method for preparing a chalcogenide optical element with electromagnetic shielding properties, comprising the following steps:

[0033] (1) Coating an inorganic film layer on the surface of the base layer of the chalcogenide optical element;

[0034] Preferably, the coating method of the inorganic film layer described in the embodiments of the present invention is electron beam evaporation or radio frequency magnetron sputtering; the coating step of the inorganic film layer includes: the background vacuum degree is less than 8× 10 -4 Pa, turn on the baking lamp before coating, heat the surface of the base layer of the chalcogenide glass coating to 50-100°C and keep it warm for 20-30min, turn on the ion source and use Ar + Ions clean the surface of the chalcogenide optical element for 15-20 minutes. After cleaning, turn on the electron gun to vapor-deposit the material of the inorganic film layer on the surface of the b...

Embodiment 1

[0059] Use ethanol-ether mixture and absolute ethanol to wipe the surface of the base layer of the flat chalcogenide optical element to the cleanliness of the coating; use the electron beam evaporation method for coating, and the background vacuum is 5×10 -4 Pa, turn on the baking lamp before coating, heat the surface of the plated chalcogenide glass window to 80°C and keep it warm for 20min, turn on the ion source and use Ar + Ion-cleaned the surface of the plated parts for 15 minutes, and finally turned on the electron gun to clean the high-purity SiO 2 The film material is evaporated to prepare SiO 2 The thickness of the film layer is 15nm; mix the silicone resin and the curing agent in a volume ratio of 30:1, stir well for 2 minutes, and mix in 5×10 -2 The vacuum degree of Pa was discharged for 15 minutes to obtain the organic colloid, and the obtained organic colloid was uniformly sprayed on the SiO 2 On the surface of the film, an organic coating is formed after it is ...

Embodiment 2

[0062] Use ethanol-ether mixture and absolute ethanol to wipe the surface of the base layer of the flat chalcogenide optical element to the cleanliness of the coating; use the radio frequency magnetron sputtering method for coating, and the background vacuum is 4×10 -4 Pa, turn on the baking lamp before coating, heat the surface of the plated chalcogenide glass window to 50°C and keep it warm for 30min, turn on the ion source and use Ar + Ions were used to ion-clean the surface of the plated part for 20 minutes, and finally the electron gun was turned on to clean the surface of the high-purity Al 2 o 3 The film material is evaporated to prepare Al 2 o 3 The thickness of the film layer is 10nm; mix the polyimide resin and the curing agent in a volume ratio of 25:1, stir well for 2min, and mix in 5×10 - 2 Under the vacuum degree of Pa, debubble 15min, obtain organic colloid, utilize the organic colloid that the organic colloid that obtains is evenly sprayed on Al 2 o 3 On ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com