Anti-oxidization and high-intensity 3D printing material for building engineering and preparation method of printing material

A technology for 3D printing and construction engineering, applied in the field of 3D printing materials, can solve the problems of oxidation resistance and strength that cannot meet the needs of existing technologies, and that the performance of polyphenylene sulfide cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

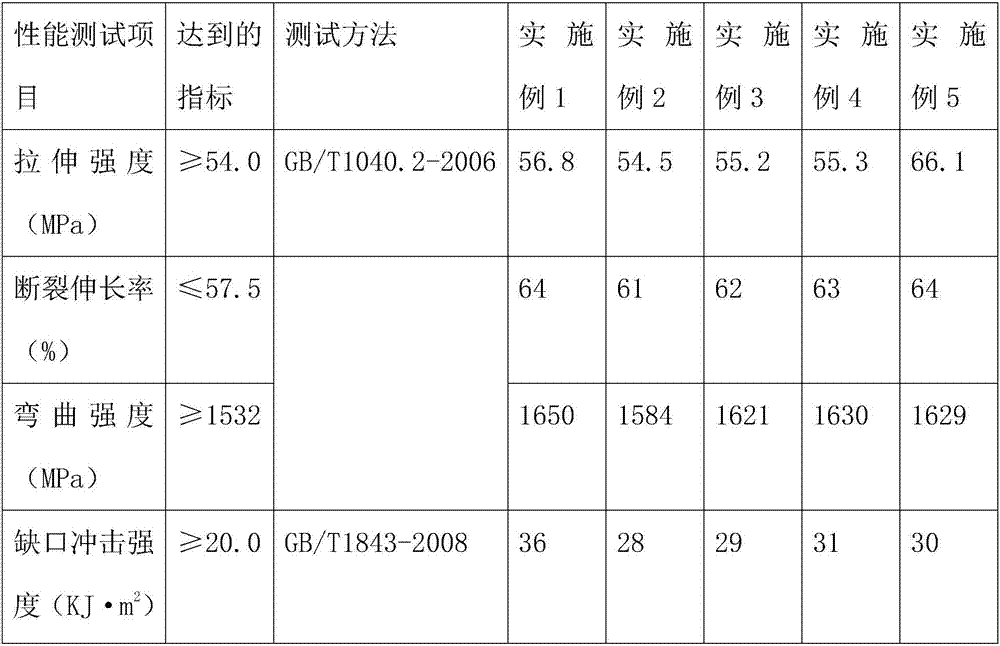

Examples

Embodiment 1

[0017] An oxidation-resistant high-strength 3D printing material for construction projects proposed by the present invention, its raw materials include: 100 parts of modified polyphenylene sulfide, 30 parts of polyphenylene sulfone, 10 parts of polycarbonate, 6.5 parts of polyvinyl chloride resin 4.5 parts of diisocyanate, 10 parts of trimethyl phosphate, 30 parts of chlorinated polyethylene, 6 parts of polytetrafluoroethylene micropowder, 8 parts of hydroxypropyl methylcellulose, 4 parts of nano-titanium dioxide, 3.5 parts of zinc borate, three 3.5 parts of antimony oxide, 6 parts of organic montmorillonite, 3 parts of glass fiber, 6 parts of nano zinc oxide, 20 parts of basalt plain weave fiber cloth, 6.5 parts of nano silicon dioxide, 3.5 parts of ethyl orthosilicate, silane coupling agent 4.5 parts of KH-570, 7.5 parts of glycerin, 2 parts of defoamer, 7.5 parts of anti-oxidation modifier, and 12 parts of modified filler.

Embodiment 2

[0019]The invention proposes an oxidation-resistant high-strength 3D printing material for construction engineering. The raw materials include: 80 parts of modified polyphenylene sulfide, 40 parts of polyphenylene sulfone, 5 parts of polycarbonate, and 9 parts of polyvinyl chloride resin. Parts, 3 parts of diisocyanate, 15 parts of trimethyl phosphate, 20 parts of chlorinated polyethylene, 9 parts of polytetrafluoroethylene micropowder, 4 parts of hydroxypropyl methylcellulose, 6 parts of nano-titanium dioxide, 2 parts of zinc borate, three 5 parts of antimony oxide, 3 parts of organic montmorillonite, 5 parts of glass fiber, 3 parts of nano zinc oxide, 30 parts of basalt plain weave fiber cloth, 4 parts of nano silicon dioxide, 5 parts of ethyl orthosilicate, silane coupling agent 3 parts of KH-570, 10 parts of glycerin, 1 part of defoamer, 9 parts of anti-oxidation modifier, and 8 parts of modified filler.

[0020] The modified polyphenylene sulfide is prepared according to ...

Embodiment 3

[0024] An oxidation-resistant high-strength 3D printing material for construction projects proposed by the present invention, its raw materials include: 120 parts of modified polyphenylene sulfide, 20 parts of polyphenylsulfone, 15 parts of polycarbonate, 4 parts of polyvinyl chloride resin 6 parts, 6 parts of diisocyanate, 5 parts of trimethyl phosphate, 40 parts of chlorinated polyethylene, 3 parts of polytetrafluoroethylene micropowder, 12 parts of hydroxypropyl methylcellulose, 2 parts of nano-titanium dioxide, 5 parts of zinc borate, three 2 parts of antimony oxide, 9 parts of organic montmorillonite, 1 part of glass fiber, 9 parts of nano zinc oxide, 10 parts of basalt plain weave fiber cloth, 9 parts of nano silicon dioxide, 2 parts of ethyl orthosilicate, silane coupling agent 6 parts of KH-570, 5 parts of glycerin, 3 parts of defoamer, 6 parts of anti-oxidation modifier, and 16 parts of modified filler.

[0025] A method for preparing an oxidation-resistant high-stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com