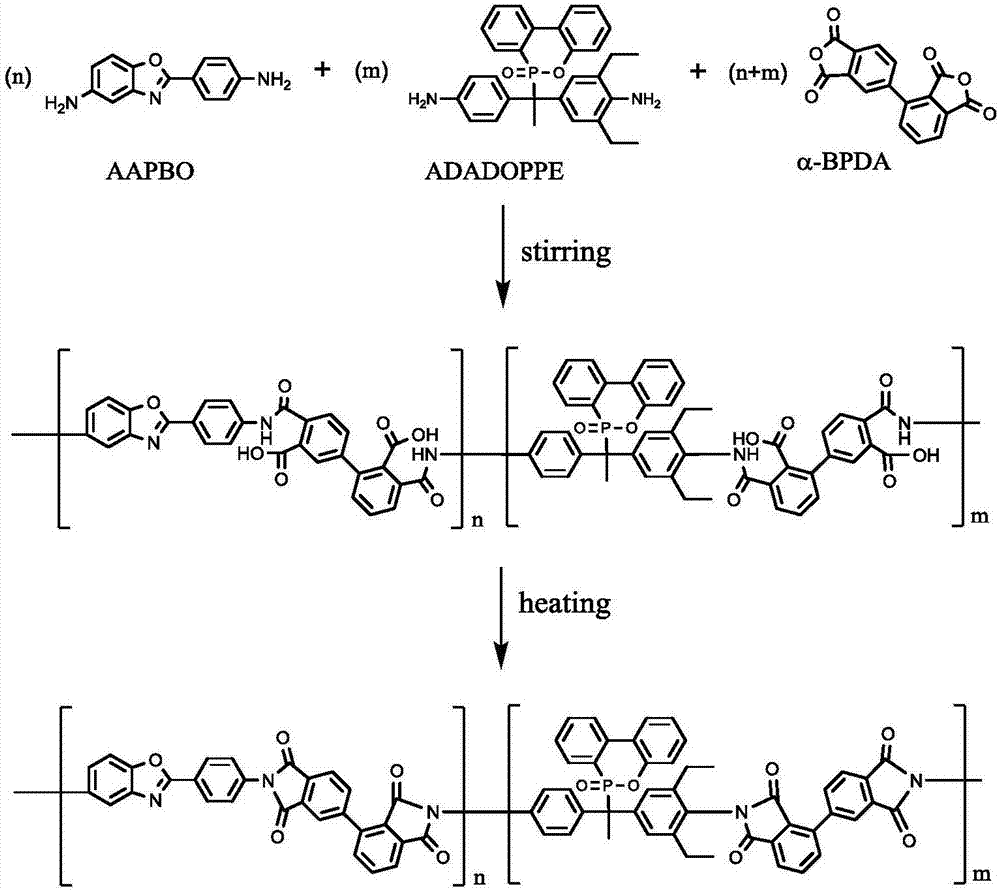

High-flame-retardancy high-strength high-transparence polyimide film and preparation method thereof

A polyimide film, high-strength technology, applied in chemical instruments and methods, organic chemistry, compounds of elements of Group 5/15 of the periodic table, etc., can solve the problems of high processing difficulty, high expansion coefficient, poor transparency, etc. , to achieve the effect of improving mechanical properties and heat resistance, strong cross-linking and rigidity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Clean all the glass instruments to be used in the experiment and dry them for later use. Add 0.0121g (0.125mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0980g (4.875mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 10.3g N,N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0032] 2) After the dissolution is completed, quickly add 1.4711g (5mmol) 2,3'3,4'-biphenyltetracarboxylic dianhydride (α-BPDA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0033] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven...

Embodiment 2

[0035] 1) Clean all the glass instruments used in the experiment and dry them for later use. Add 0.0243g (0.25mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0699g (4.75mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 10.3g N,N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0036] 2) After the dissolution is completed, quickly add 1.4711g (5mmol) 2,3'3,4'-biphenyltetracarboxylic dianhydride (α-BPDA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0037] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven to bake t...

Embodiment 3

[0039] 1) Clean all the glass instruments used in the experiment and dry them for later use. Add 0.0362g (0.375mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0417g (4.625mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 14.8g N, N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0040] 2) After the dissolution is completed, quickly add 1.4711g (5mmol) 2,3'3,4'-biphenyltetracarboxylic dianhydride (α-BPDA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0041] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com