Preparation method of antireflection structure and antireflection structure

An anti-reflection and particle technology, applied in the field of display, can solve the problem of high cost of anti-reflection structure preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

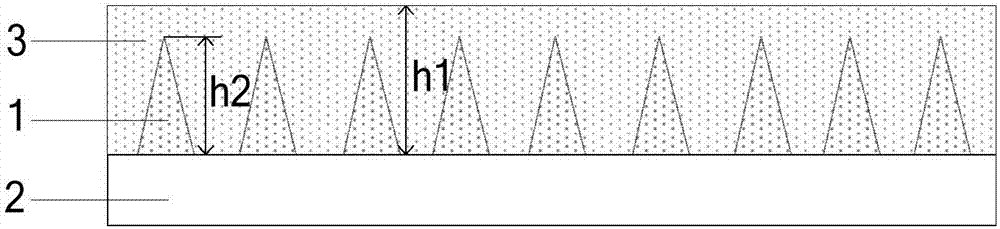

[0029] Embodiment 1 of the present invention provides a method for preparing an anti-reflection structure, combining figure 1 with figure 2 As shown, the preparation method of the anti-reflection structure includes the following steps:

[0030] In step 1, a plurality of particles 1 are mixed with a polymer solution 3 .

[0031] Specifically, physical methods, such as mechanical stirring or ultrasonic dispersion, can be used to disperse the particles 1 in the polymer solution 3, or chemical methods can be used, such as changing the structure or charge distribution on the surface of the particles 1, so that Particles 1 are dispersed in a polymer solution 3 .

[0032] The material of particle 1 can be metal, such as silver, aluminum, gold or copper, also can be metal oxide, such as zinc oxide, manganese oxide or vanadium oxide, can also be organic compound, such as polystyrene, polymethacrylate Polyester, polyurethane or polycarbonate, of course, alloys composed of various me...

Embodiment 2

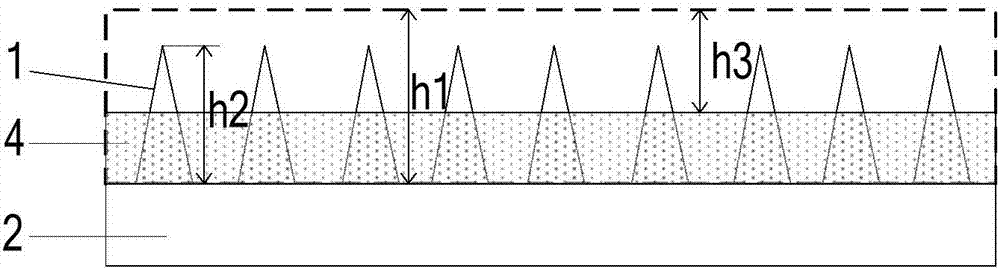

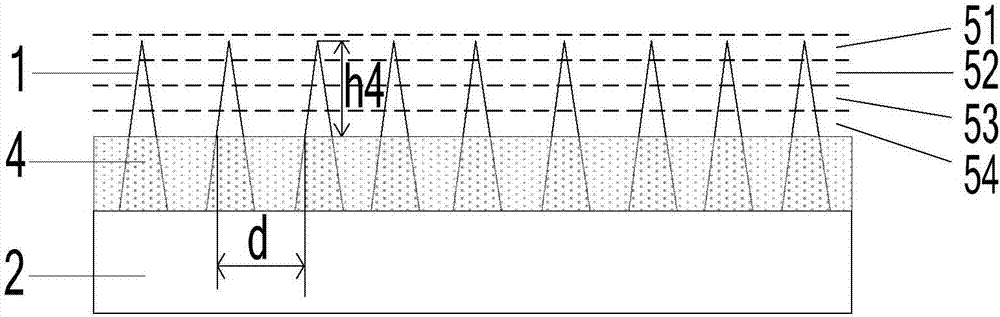

[0043] Embodiment 2 of the present invention provides an anti-reflection structure, such as image 3 As shown, the anti-reflection structure is formed on the substrate 2 using the method provided in Example 1, the anti-reflection structure includes a polymer film 4 doped with a plurality of particles 1 formed on the substrate 2, and the particles 1 are exposed Outside the polymer film 4.

[0044]In the anti-reflection structure provided by Embodiment 2 of the present invention, since the particles 1 are exposed outside the polymer film 4, and the particles 1 have a certain geometric shape, the surface of the polymer film 4 is relatively rough. When the surface is rough, the reflectivity of the anti-reflection structure to light is low, thereby reducing the specular reflection of light.

[0045] Preferably, the particle 1 is a nanoparticle, so that when light is incident on the surface of the nanoparticle, the nanoparticle can generate surface plasmon resonance with the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com