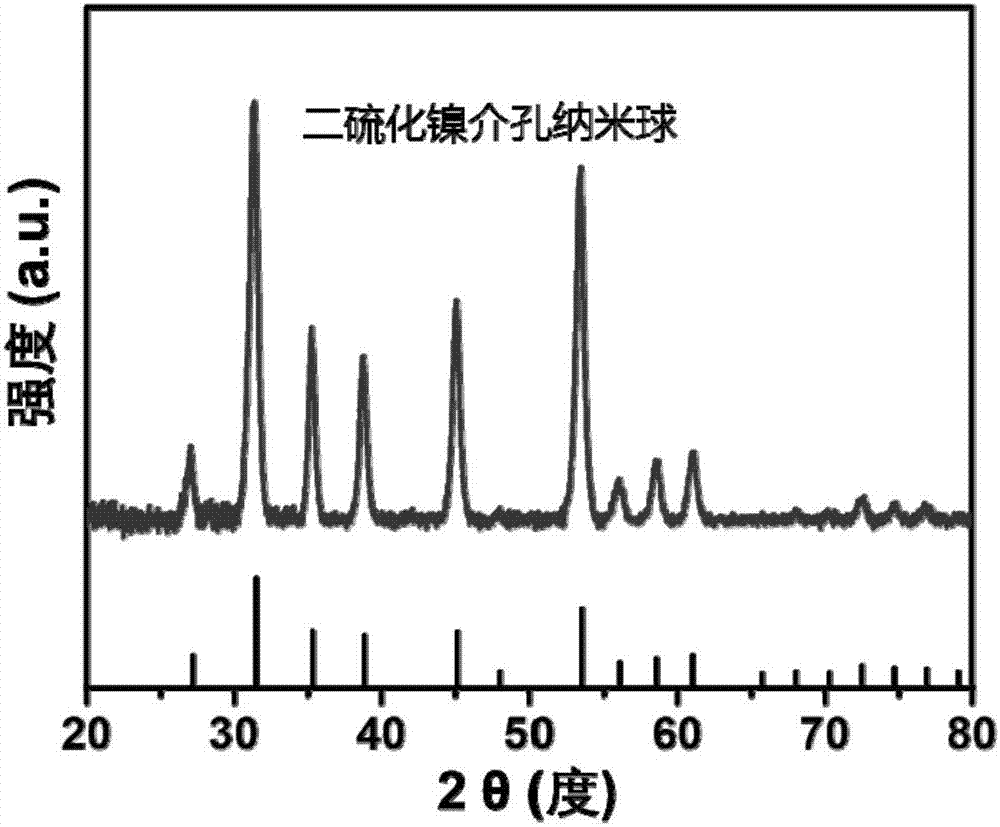

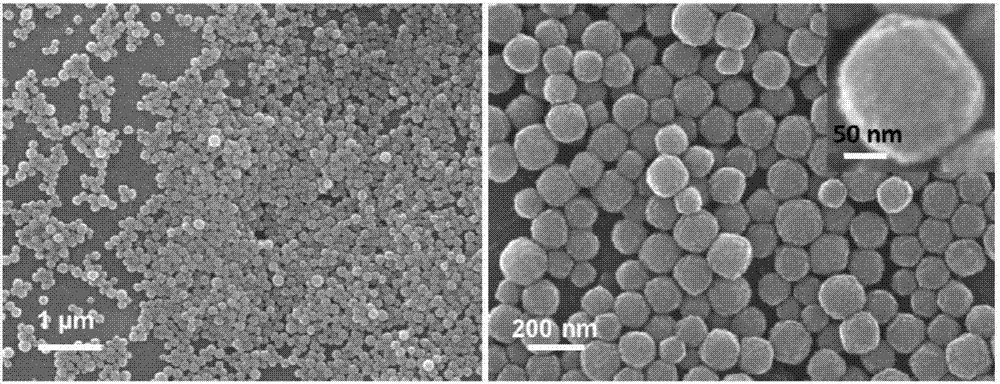

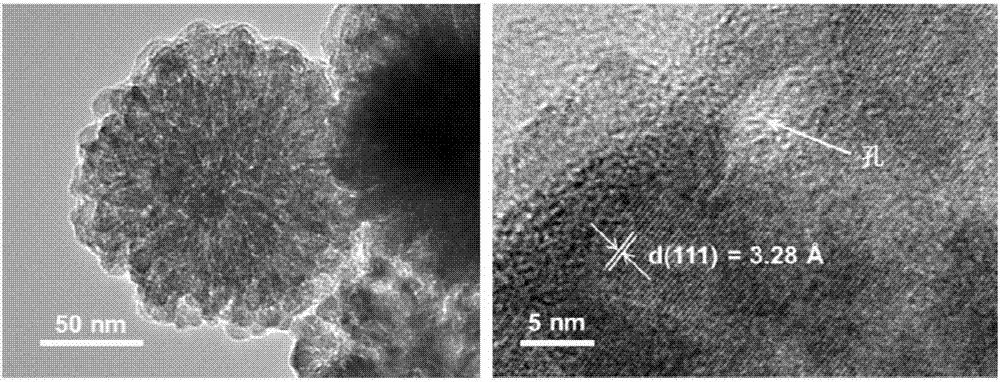

NiS2 mesoporous nanosphere material, preparation method thereof and application

A nanosphere and mesoporous technology, applied in the fields of nanomaterials and electrochemistry, to achieve low production costs, improve cycle stability, and slow down severe structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] NeS 2 The preparation method of mesoporous nanosphere material, it comprises the following steps:

[0033] 1) Take a certain amount of ethylene glycol solution and disperse it in an appropriate amount of deionized water. The ratio of ethylene glycol to deionized water in the uniform mixed solution is 1:1, and stir until uniform;

[0034] 2) Slowly add a certain amount of polyvinylpyrrolidone (PVP K-30) powder to the solution obtained in step 1), and its concentration in the solution is 0.006g mL -1 , stir until completely dissolved;

[0035]3) Slowly add a certain amount of C to the obtained step 2) 4 h 6 o 4 Ni·4H 2 O powder, its concentration in solution is 0.02mmolmL -1 , magnetic stirring until completely dissolved;

[0036] 4) in step 3) in the gained solution, be 1 / 6 to add a certain amount of Na by nickel / sulfur molar ratio 2 S 2 o 3 ·5H 2 O, magnetic stirring until completely dissolved;

[0037] 5) Transfer the solution obtained in step 4) to a polyt...

Embodiment 2

[0042] NeS 2 The preparation method of mesoporous nanosphere material, it comprises the following steps:

[0043] 1) Take a certain amount of ethylene glycol solution and disperse it in an appropriate amount of deionized water. The ratio of ethylene glycol to deionized water in the uniform mixed solution is 1:1, and stir until uniform;

[0044] 2) Slowly add a certain amount of polyvinylpyrrolidone (PVP K-30) powder to the solution obtained in step 1), and its concentration in the solution is 0.008g mL -1 , stir until completely dissolved;

[0045] 3) Slowly add a certain amount of C to the obtained step 2) 4 h 6 o 4 Ni·4H 2 O powder, its concentration in solution is 0.02mmolmL -1 , magnetic stirring until completely dissolved;

[0046] 4) in step 3) in the gained solution, be 1 / 6 to add a certain amount of Na by nickel / sulfur molar ratio 2 S 2 o 3 ·5H 2 O, magnetic stirring until completely dissolved;

[0047] 5) Transfer the solution obtained in step 4) to a poly...

Embodiment 3

[0051] NeS 2 The preparation method of mesoporous nanosphere material, it comprises the following steps:

[0052] 1) Take a certain amount of ethylene glycol solution and disperse it in an appropriate amount of deionized water. The ratio of ethylene glycol to deionized water in the uniform mixed solution is 1:1, and stir until uniform;

[0053] 2) Slowly add a certain amount of polyvinylpyrrolidone (PVP K-30) powder to the solution obtained in step 1), and its concentration in the solution is 0.01g mL -1 , stir until completely dissolved;

[0054] 3) Slowly add a certain amount of NiCl to the obtained in step 2) 2 ·6H 2 O, its concentration in solution is 0.02mmolmL -1 , magnetic stirring until completely dissolved;

[0055] 4) in step 3) in the gained solution, be 1 / 6 to add a certain amount of Na by nickel / sulfur molar ratio 2 S 2 o 3 ·5H 2 O, magnetic stirring until completely dissolved;

[0056] 5) Transfer the solution obtained in step 4) to a polytetrafluoroeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com