Preparation method of cnts/ti biomimetic micro-nano laminated composite material

A composite material, micro-nano technology, applied in coating, manufacturing tools, metal rolling, etc., can solve the problem that CNTs are difficult to distribute evenly, and achieve the effect of improving uniform plastic deformation ability and reducing elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

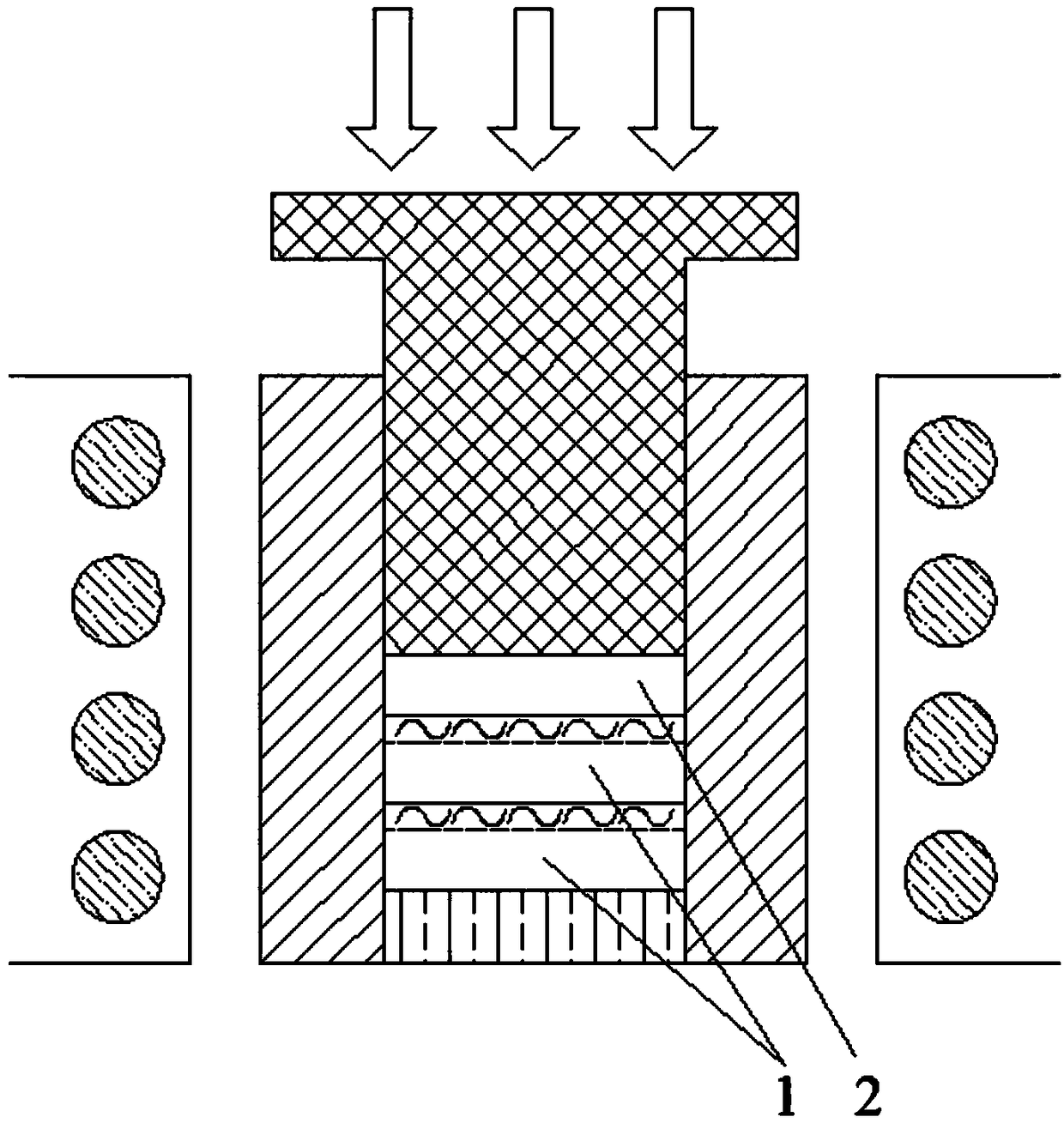

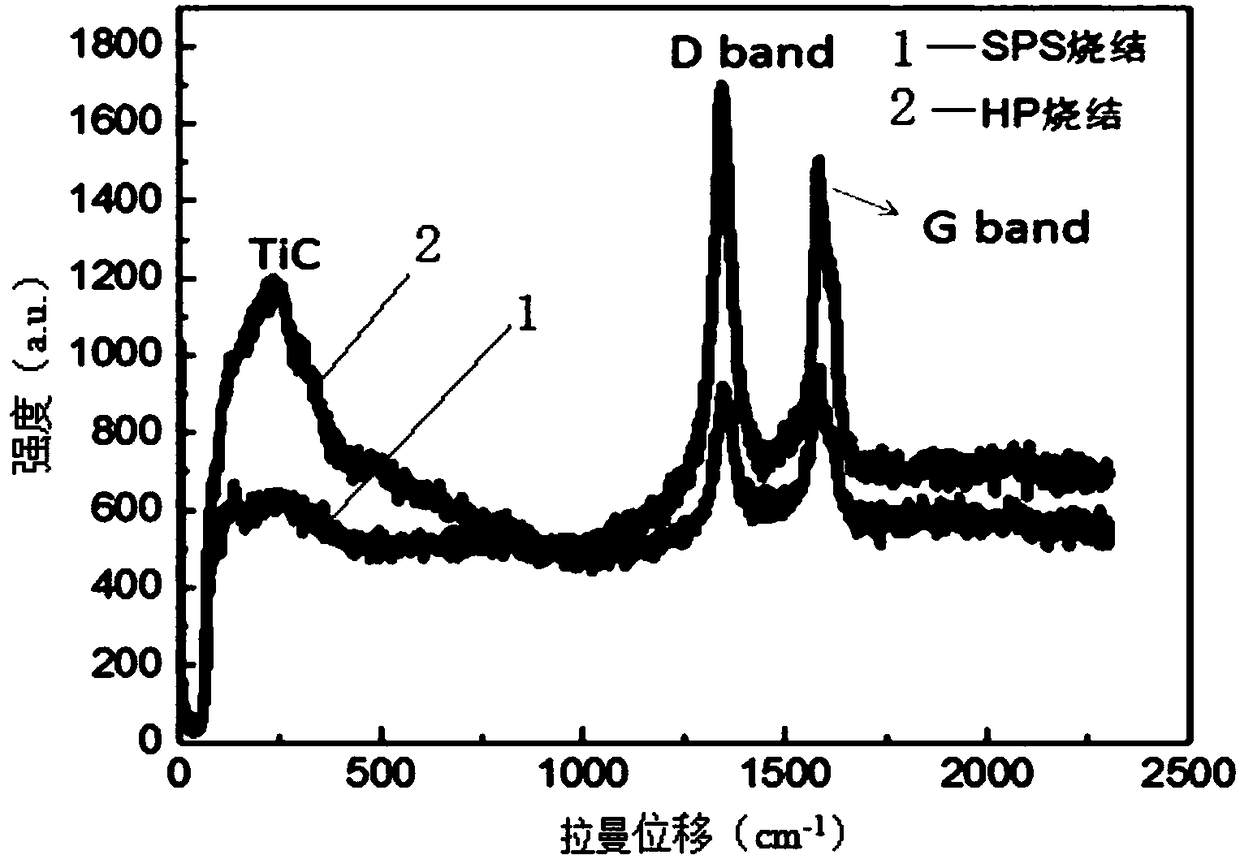

[0032] Specific embodiment one: the preparation method of CNTs / Ti biomimetic micro-nano laminated composite material in this embodiment is carried out according to the following steps:

[0033] Step 1. Raw material pretreatment: take a commercial TA1 pure titanium foil with a thickness of 50 μm, and use a volume concentration of 15% HF solution to pretreat the surface of the titanium foil for 10 seconds to remove the oxide film, etc.; carbon nanotube dispersion treatment: first use a volume ratio of 0.3g of carbon nanotubes were acidified with a mixed acid prepared with 2:1 concentrated sulfuric acid and concentrated nitric acid for 5 hours, then diluted to neutrality, and then centrifuged;

[0034] Step 2, prepare a mixed solution with absolute ethanol and acetone with a volume ratio of 1:2, take 500ml, add 0.06g of Al(NO 3 ) 3 and 0.2g of the acidified carbon nanotubes in step 1, ultrasonically dispersed for 8 hours to obtain a CNTS suspension;

[0035]Step 3. Use the tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com