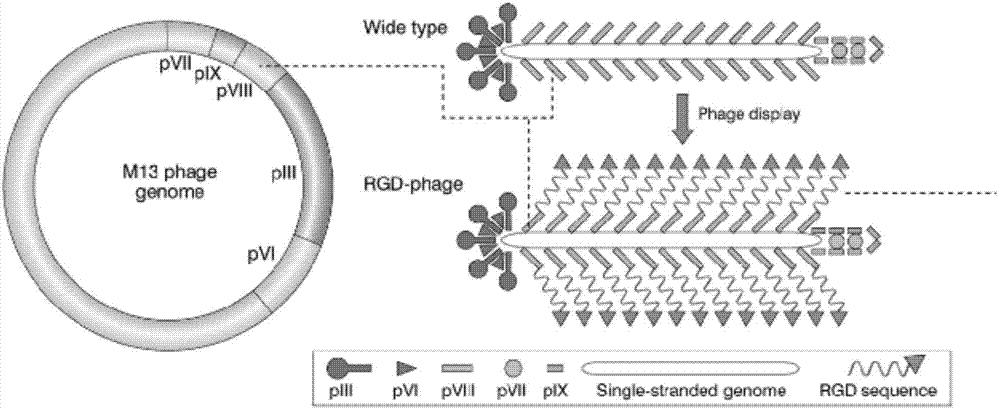

RGD phage/fibroin composite hemostatic material and preparation method thereof

A hemostatic material and bacteriophage technology, applied in the field of biomedical materials, can solve problems such as lack of mechanical properties and discomfort, and achieve the effect of accelerating hemostasis speed and effect, high biocompatibility, and increasing platelet adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation method of RGD phage / silk fibroin hemostatic material with controllable degradation

[0067] 1) The fibrous silk fibroin obtained after silkworm cocoon degumming is sequentially dissolved, filtered, dialyzed and centrifuged, and concentrated to a silk fibroin aqueous solution with a mass percentage of 100 mg / mL;

[0068] 2) Set the concentration to 10 7 The pfu / mL phage solution is ultrasonically dispersed, mixed with the silk fibroin solution, and stirred evenly to obtain the RGD phage / silk fibroin composite solution;

[0069] 3) Vacuum freeze-drying at -20°C for 24 hours to obtain a three-dimensional porous RGD phage / silk fibroin composite hemostatic material;

[0070] 4) Treatment with 30% alcohol can control the degradation rate of the three-dimensional porous RGD phage / silk fibroin hemostatic material within one day.

Embodiment 2

[0072] The preparation method of the RGD phage / silk fibroin hemostatic material of controllable degradation comprises the following steps:

[0073] 1) The fibrous silk fibroin obtained after silkworm cocoon degumming is successively dissolved, filtered, dialyzed and centrifuged, and then concentrated to a silk fibroin aqueous solution with a mass percentage of 1 mg / mL;

[0074] 2) Set the concentration to 10 14 The pfu / mL phage solution is ultrasonically dispersed, mixed with the silk fibroin solution, and stirred evenly to obtain the RGD phage / silk fibroin composite solution;

[0075] 3) Vacuum freeze-drying at -80°C for 48 hours to obtain a three-dimensional porous RGD phage / silk fibroin composite hemostatic material;

[0076] 4) When treated with 80% alcohol, the degradation rate of the three-dimensional porous RGD bacteriophage / silk fibroin hemostatic material can be basically not degraded (the dissolution rate is greater than 80% after 1 month).

Embodiment 3

[0078] The preparation method of the RGD phage / silk fibroin hemostatic material with controllable degradation adopts the following steps:

[0079] 1) The fibrous silk fibroin obtained after silkworm cocoon degumming is sequentially dissolved, filtered, dialyzed and centrifuged, and then concentrated to a silk fibroin aqueous solution with a mass percentage of 0.1 mg / mL;

[0080] 2) Set the concentration to 10 20 The pfu / mL phage solution is ultrasonically dispersed, mixed with the silk fibroin solution, and stirred evenly to obtain the RGD phage / silk fibroin composite solution;

[0081] 3) Obtain a three-dimensional porous RGD phage / silk fibroin composite hemostatic material by freeze-drying;

[0082] 4) Take 2 mL of fresh rabbit blood, put the prepared RGD phage / silk fibroin composite hemostatic material into the fresh rabbit blood, and the fresh rabbit blood coagulates after 3 minutes.

[0083] Therefore, the process of the present invention is simple, and supramolecular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com