Magnetism-insulating sheet with protecting film and preparation method

A technology of magnetic isolation sheet and protective film, which is applied in the manufacture of permanent magnets, inductors/transformers/magnets, magnets, etc., can solve the problems of low cost and high efficiency of magnetic isolation sheets, and achieves low cost, simple and easy method, good performance The effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

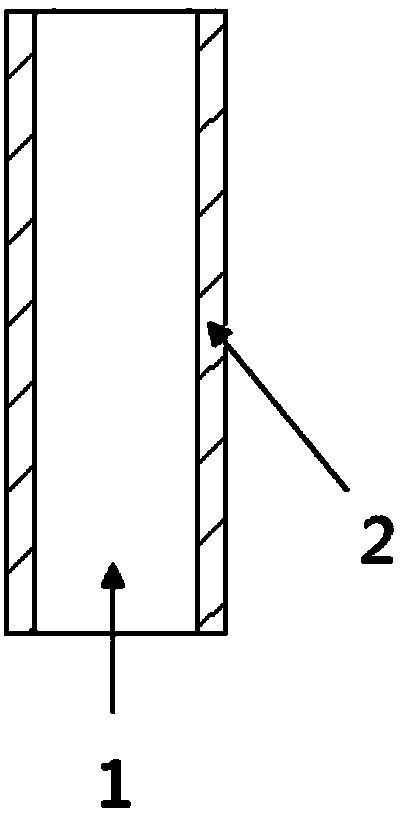

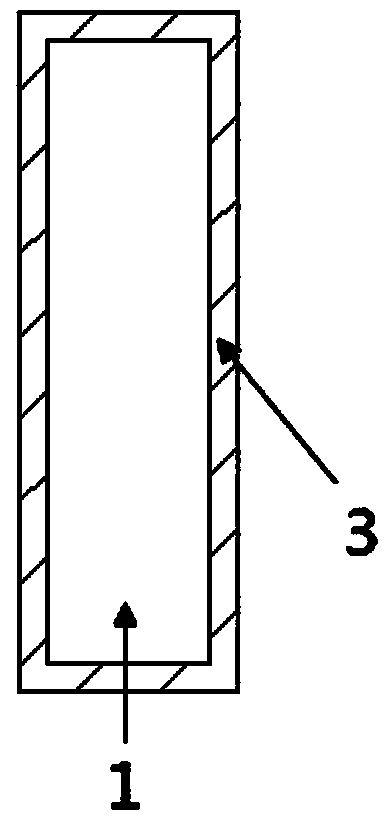

[0038] Such as figure 1 As shown, in the prior art, the PET adhesive tape 2 is generally used to bond the surface of the magnetic isolation sheet 1. The PET adhesive tape 2 is generally cut in batches, and the cutting itself has errors, so it is easy to be mismatched when it is attached to the magnetic isolation sheet. If manual lamination is used, the efficiency is relatively low, and manual lamination also has certain errors; if the size of the magnetic isolation sheet 1 is measured by a machine, and then the PET sticker 2 is cut according to the magnetic isolation sheet 1, although the PET sticker 2 is solved to a certain extent. The problem of mismatching the size of the combination and the magnetic isolation sheet, but the cost is relatively high. And adopt these two kinds of methods to carry out lamination to the magnetic isolating sheet and all have the situation that the side of the magnetic isolating sheet 1 is not coated, so the waterproof, moisture-proof property of...

Embodiment 2

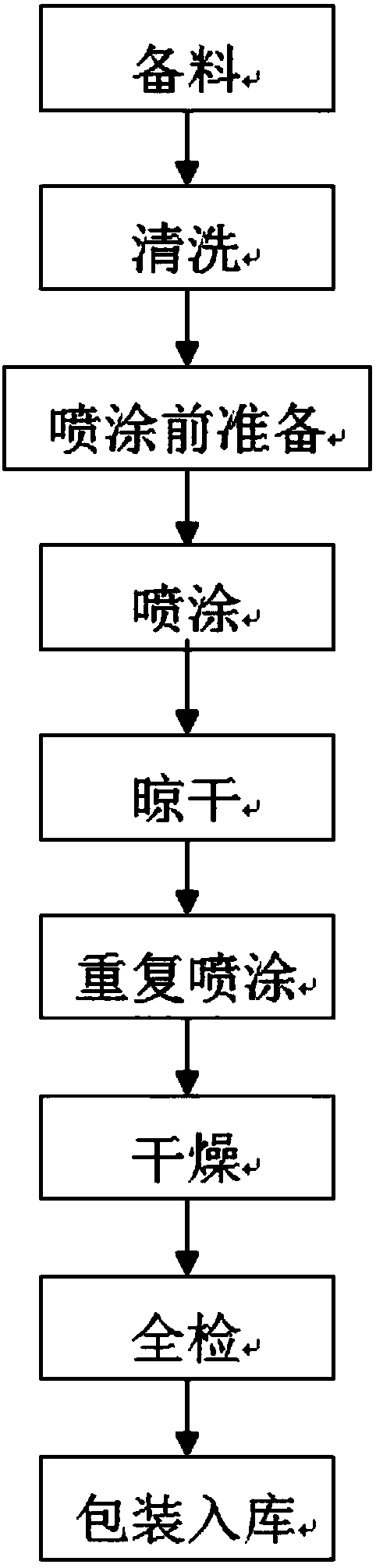

[0047] Such as image 3 Shown, the method for spraying rubber paint on the surface of the magnetic isolation sheet comprises the following steps:

[0048] Material preparation: Prepare the magnetic sheet to be sprayed, the rubber paint and thinner for spraying.

[0049] Cleaning: Clean the surface of the magnetic sheet to be sprayed to ensure that the surface is clean and free of dust and moisture.

[0050] Preparation before spraying: Stir the rubber paint evenly and adjust the appropriate viscosity with a special thinner, then inject it into the paint container. There is a stirring device in the container to keep the paint uniform and not precipitated. Turn on the air supply and exhaust system of the spraying workshop, and blow the working environment with compressed air to remove dust.

[0051] Spraying environment requirements: dust-free, room temperature between 15 and 35 degrees, humidity <80%.

[0052] Spray gun: gravity spray gun or siphon spray gun, nozzle diamete...

Embodiment 3

[0067] Such as Figure 4 Shown, the method for dipping the rubber coating on the surface of the magnetic isolation sheet comprises the following steps:

[0068] Material preparation: Prepare the magnetic sheet to be sprayed, the paint and special thinner for spraying.

[0069] Cleaning: Clean the surface of the magnetic sheet to be sprayed to ensure that the surface is clean and free of dust and moisture.

[0070] Preparation before dipping: Stir the paint evenly and adjust the appropriate viscosity with a special thinner, and then pour it into the dipping tank. There is a stirring device in the dipping tank to keep the paint uniform and not precipitated. Open the air supply and exhaust system of the impregnation workshop, and blow the working environment with compressed air to remove dust.

[0071] Operating environment requirements: dust-free, room temperature between 15 and 35 degrees, humidity <80%.

[0072] Dipping: Place the cleaned magnetic sheet to be coated on a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com