Mobile phone 3D glass positioning and processing system and method

A processing system and processing method technology, applied in general control system, control/adjustment system, computer control, etc., can solve the problems of fragility, low strength, and gaps in assembly, so as to increase the falling ball and static pressure value, increase Product strength, smooth edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

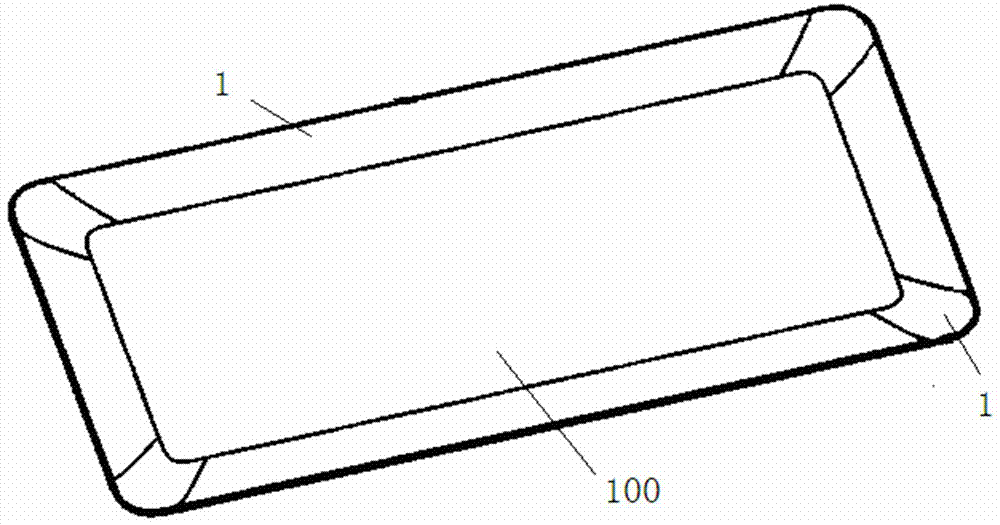

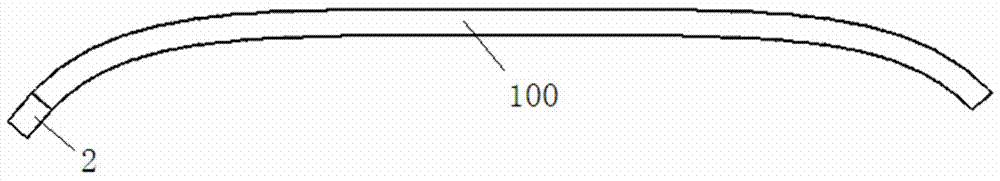

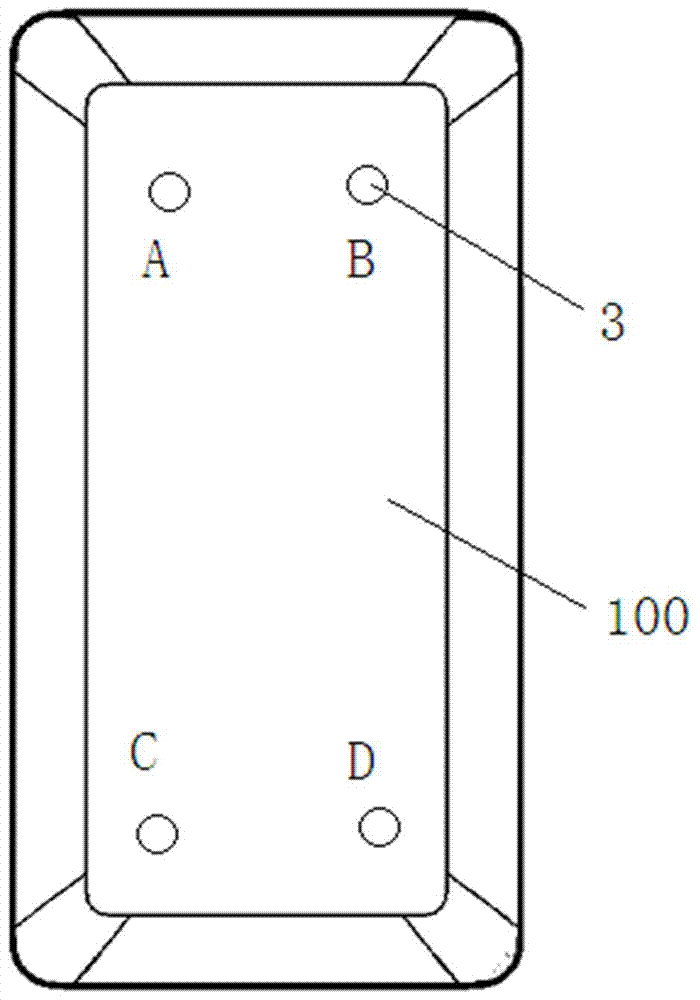

[0047] The specific implementation of the mobile phone 3D glass positioning processing system and processing method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] Mobile 3D glass positioning processing system includes CNC machine head, probe and CNC machine control unit, mobile 3D glass is fixed on the processing table, probe is installed on the CNC machine head, and at least three thickness measurements are determined on the surface of mobile 3D glass Position, the CNC machine tool control unit controls the probe to probe at the thickness measurement position, obtains the average thickness of the mobile phone 3D glass surface and determines the processing amount, determines at least two edge direction positions on the side of the mobile phone 3D glass, and the CNC machine tool control unit controls the probe The needle probes the position in the edge direction to obtain the boundary line of the 3D glass of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com