Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

A composite intermediate layer, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, to improve welding quality, prevent non-fusion, and improve the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Adopt the method of the present invention to carry out the welding of stainless steel-titanium alloy dissimilar metal:

[0041] First, the titanium alloy plate 1 and the stainless steel plate 3 are clamped on the welding positioning platform 5 with the pressure plate 4; a composite intermediate layer 2 with a thickness of 1.4mm is placed between the titanium alloy plate 1 and the stainless steel plate 3, and the pre-tightening force The adjustment screw 6 maintains a certain pressure between the titanium alloy plate-composite intermediate layer-stainless steel plate.

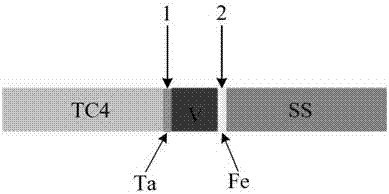

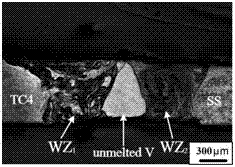

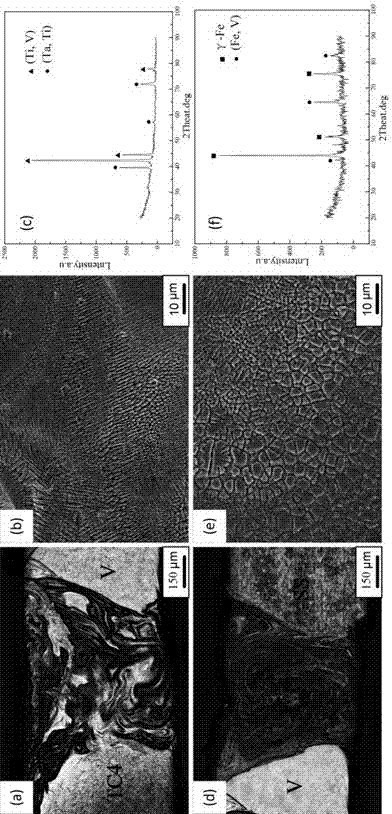

[0042] Two-pass welding is used to precisely control the welding process parameters. During the first welding, the laser spot is irradiated on the center line of the Ta intermediate layer, so that the Ta intermediate layer is completely melted, and the titanium alloy and the V part are melted to form a titanium alloy-vanadium weld; the second During the two-pass welding, the laser spot is irradiated on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com