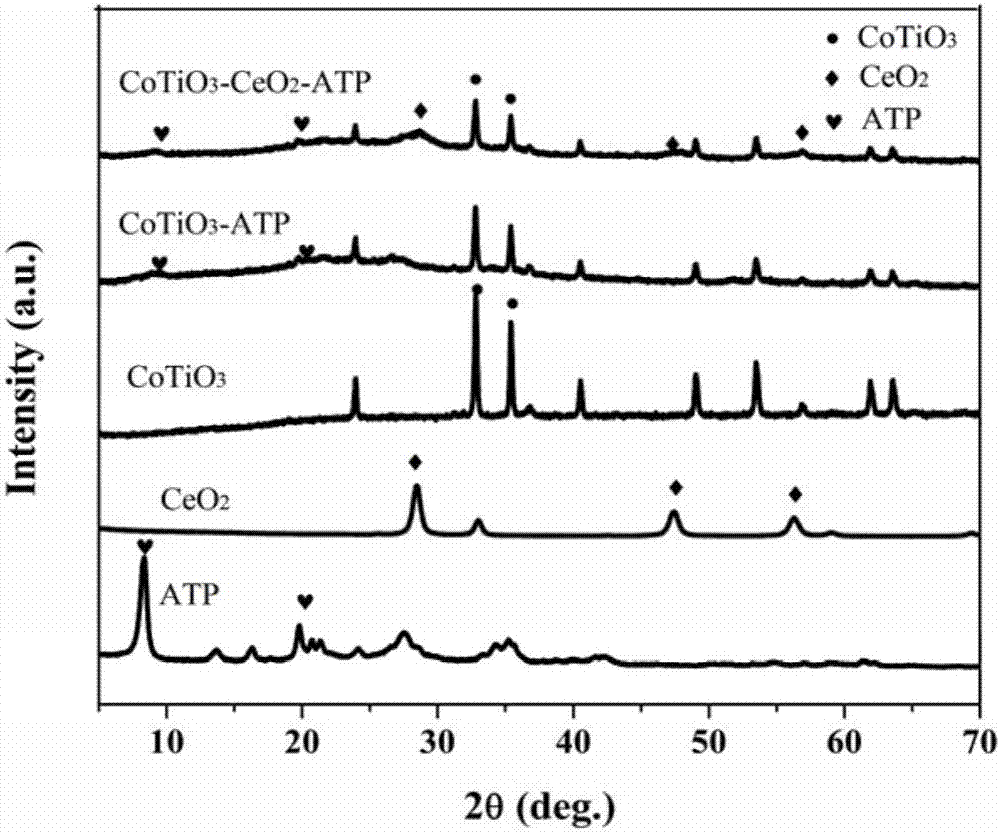

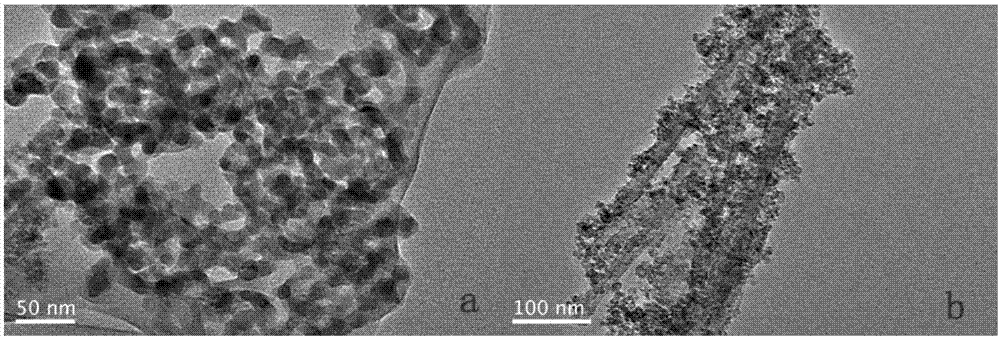

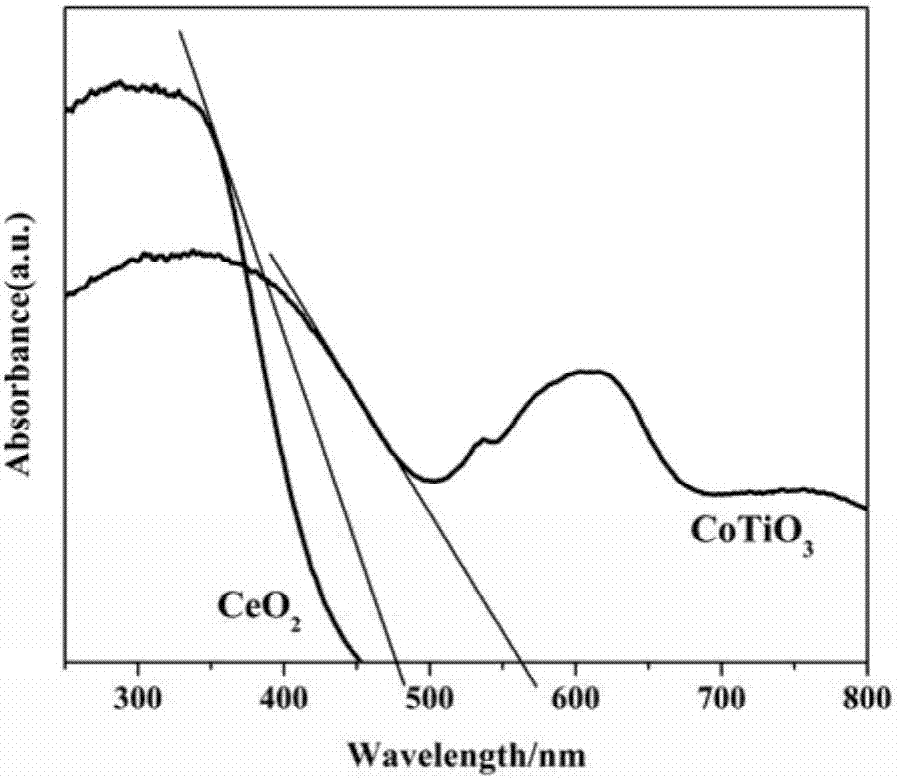

Attapulgite-supported CoTiO3-CeO2-heterojunction SCR low-temperature denitrification catalyst and preparation method thereof

A low-temperature denitrification and attapulgite technology, which is applied in the field of flue gas denitrification, can solve the problems of strong reaction conditions, more secondary pollution, and narrow activity range, and achieve the effects of lower reaction temperature, less secondary pollution, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Fully disperse attapulgite in ethanol to obtain a dispersion with a concentration of 5g / 100mL, measure 100mL of the dispersion, and add 1.0g of Ce(NO 3 ) 3 ·6H 2 0, fully stirred at room temperature for 2 hours to obtain a mixed slurry; after the stirring was completed, adjust the pH=7 of the mixed slurry with ammonia water, after continuing to stir for 1 hour, suction filter and wash the filter cake with deionized water to neutrality, and dry at 80 ° C. Get CeO 2 / ATP;

[0020] (2) Dissolve 1.5g of cobalt acetate tetrahydrate, 1.4g of tetrabutyl titanate, and 2.26g of citric acid in 20ml of ethanol, and add them to a three-necked flask in turn, and stir at 70°C for 0.5h until the solution forms a sol state. ,

[0021] (3) CeO prepared in step (1) 2 / ATP ground and sieved, dispersed in absolute ethanol to obtain a dispersion with a concentration of 5g / 100mL, and added to the sol obtained in step (2), sealed to prevent evaporation and stirred for 1h, then dried ...

Embodiment 2

[0030] (1) Fully disperse attapulgite in ethanol to obtain a dispersion with a concentration of 5g / 100mL, measure 100mL of the dispersion, and add 0.52g of Ce(NO 3 ) 3 ·6H 2 0, fully stirred at room temperature for 2 hours to obtain a mixed slurry; after the stirring was completed, adjust the pH=7 of the mixed slurry with ammonia water, after continuing to stir for 1 hour, suction filter and wash the filter cake with deionized water to neutrality, and dry at 80 ° C. Get CeO 2 / ATP;

[0031] (2) Dissolve 1g of cobalt acetate tetrahydrate, 1.4g of tetrabutyl titanate and 1.5g of citric acid in 20ml of ethanol, and add them to a three-necked flask in turn, and stir at 70°C for 0.5h until the solution forms a sol state.

[0032] (3) with embodiment 1.

Embodiment 3

[0034] (1) Fully disperse attapulgite in ethanol to obtain a dispersion with a concentration of 5g / 100mL, measure 100mL of the dispersion, and add 0.86g of Ce(NO 3 ) 3 ·6H 2 0, fully stirred at room temperature for 2 hours to obtain a mixed slurry; after the stirring was completed, adjust the pH=7 of the mixed slurry with ammonia water, after continuing to stir for 1 hour, suction filter and wash the filter cake with deionized water to neutrality, and dry at 80 ° C. Get CeO 2 / ATP;

[0035] (2) Dissolve 1.5g of cobalt acetate tetrahydrate, 2.1g of tetrabutyl titanate, and 2.26g of citric acid in 20ml of ethanol, and add them to a three-necked flask in sequence, and stir at 70°C for 0.5h until the solution forms a sol state ,

[0036] (3) with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com