Phenyl boronic acid modified silica gel functional chromatographic filler, preparation method and applications thereof

A chromatographic filler and phenylboronic acid-functional technology, which is applied in the field of preparation of phenylboronic acid-modified silica gel functional chromatography fillers, and achieves the effects of novel structure, mild reaction conditions and development promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

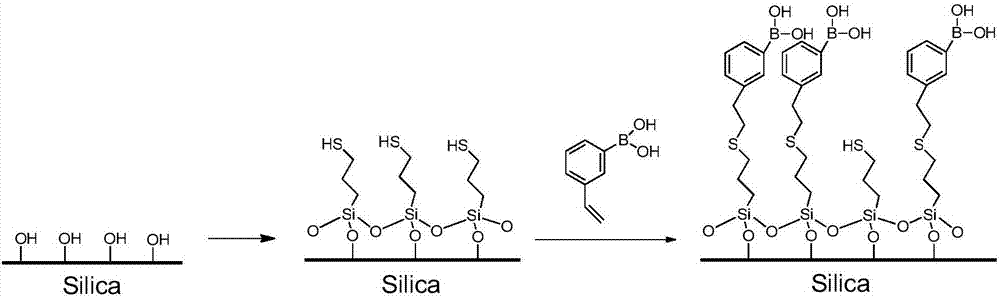

Embodiment 1

[0051] Weigh 5g of spherical silica gel (particle size 5μm, pore size Specific surface 300m 2 / g), placed in a 250mL three-necked flask, adding 80mL concentration of hydrochloric acid solution of 2mol / L, heated to reflux for 12 hours, cooled to room temperature, with 4 # Suction filter through a sand core funnel, wash with water until neutral, drain and dry in an oven at 80°C overnight to obtain activated silica gel. Under the condition of blowing dry nitrogen, add 50mL of dry toluene to the activated silica gel, stir evenly, then dropwise add 5.9mL of γ-triethoxypropylmercaptosilane, heat and reflux at 110°C for 24 hours, and use 4 # Suction filter the funnel with a sand core, wash it with toluene, acetone, water, and methanol in sequence, drain it and dry it in an oven at 80°C overnight to obtain mercaptosilica gel. Under the condition of passing dry nitrogen, weigh 5g of mercapto silica gel, add 50mL of anhydrous methanol, stir well, add 0.5g of 3-vinylphenylboronic aci...

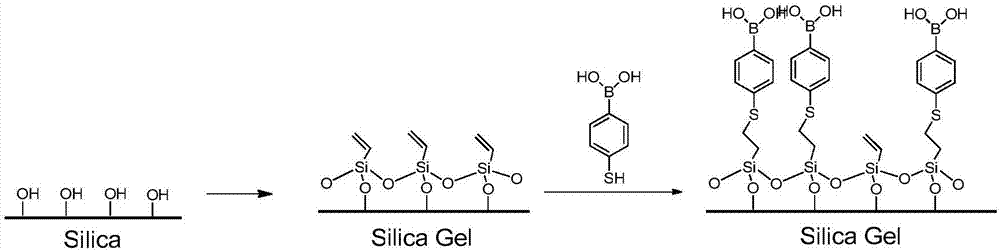

Embodiment 2

[0053] Weigh 5g of spherical silica gel (particle size 5μm, pore size Specific surface 300m 2 / g), placed in a 250mL three-necked flask, adding 80mL concentration of hydrochloric acid solution of 2mol / L, heated to reflux for 12 hours, cooled to room temperature, with 4 # Suction filter through a sand core funnel, wash with water until neutral, drain and dry in an oven at 80°C overnight to obtain activated silica gel. Under the condition of blowing dry nitrogen, add 50mL of dry toluene to the activated silica gel, stir evenly, then dropwise add 2.6mL of vinyltrichlorosilane, heat and reflux at 50°C for 24 hours, and finish the reaction with 4 # Suction filter the funnel with a sand core, wash it with toluene, acetone, water, and methanol in sequence, drain it and dry it in an oven at 60°C overnight to obtain vinyl silica gel. Under the condition of passing dry nitrogen, weigh 5g of vinyl silica gel, add 50mL of anhydrous methanol, stir evenly, add 0.5g of 4-mercaptophenylbor...

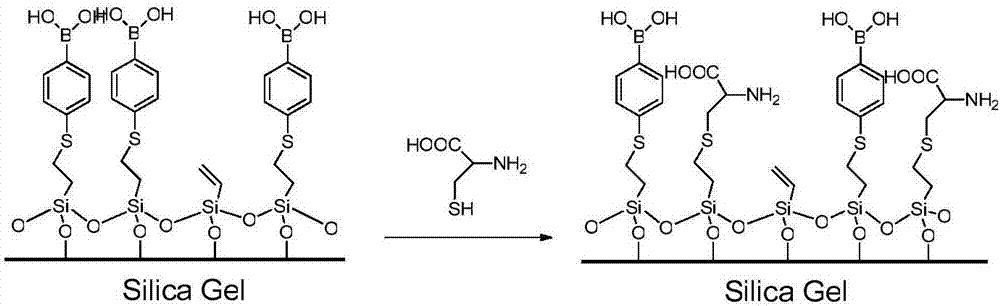

Embodiment 3

[0055] Weigh 3g of the material phenylboronic acid modified filler II in Example 2, put it in a 250mL three-necked flask, add 50mL of anhydrous methanol, stir evenly, add 3g of cysteine dissolved in 5mL of deionized water, stir evenly, add Dissolve 0.06g of 2,2-azobisisobutyronitrile in 5mL of anhydrous methanol, stir well, heat up to 65°C, heat to reflux for 48 hours, cool the reaction system to room temperature, 4 # The funnel with a sand core was subjected to suction filtration, washed with water and methanol in sequence, drained and dried overnight in an oven at 80°C to obtain phenylboronic acid-modified filler III, elemental analysis results: C5.96%, N0.77%, H1.38%, prepared Process such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com