Preparation method of glycyrrhizic acid

A technology of glycyrrhizic acid and glycyrrhizic acid monoammonium salt, which is applied in the direction of steroids and organic chemistry, can solve the problems of long production process period of glycyrrhizic acid, low product yield, and many impurities, and achieve high production safety and high yield. The effect of high efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

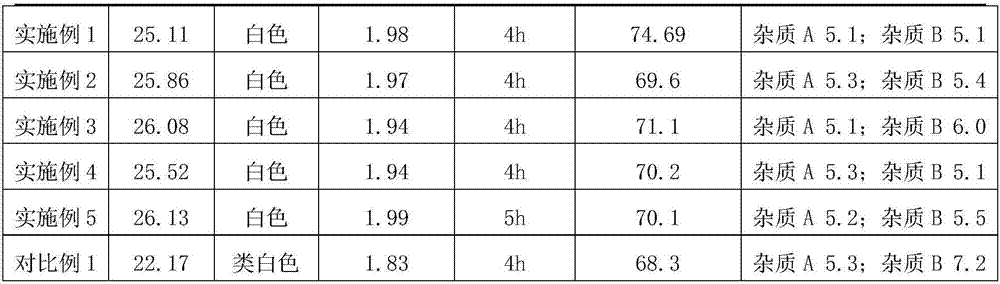

Embodiment 1

[0038] Embodiment 1: get pulverized back and sieve (60-80 order) back glycyrrhizic acid coarse powder 100g, add the 80% ethanol of 800ml, extract 2 hours at 30 ℃ of temperature, obtain extract, 3g ammonium acetate is added extract, Add 0.1 g of formic acid, continue to stir for 0.5-1 h, transfer to room temperature for stirring and crystallization, and filter after 4 hours to obtain the crude product of monoammonium glycyrrhizinate. Get the crude product of monoammonium glycyrrhizic acid salt, add model is D001 strongly acidic cationic resin 20g, add 80% methyl alcohol of 20ml in the resin and carry out conversion under room temperature condition, obtain glycyrrhizic acid solution after conversion is completed, add 3g gradually at 30 DEG C ammonium acetate and 0.1g of formic acid, continuously stirred for 0.5-1h, transferred to room temperature for stirring and crystallization, filtered after 4 hours, and dried at 70°C for 5h to obtain 25.11g of monoammonium glycyrrhizinate, th...

Embodiment 2

[0040]Embodiment 2: get pulverized back and sieve (60-80 mesh) back glycyrrhizic acid coarse powder 100g, add the 95% ethanol of 1000ml and extract at 45 ℃ of temperature for 3 hours, extract solution adds the ammonium acetate of 8g and 2g at the same temperature The formic acid solution was continuously stirred for 0.5-1h, transferred to room temperature for stirring and crystallization, and filtered after 4 hours to obtain the crude product of monoammonium glycyrrhizinate. The test results of the crude monoammonium glycyrrhizinate are shown in Table 1. Get the monoammonium glycyrrhizinate crude product of gained glycyrrhizinate, add the strongly acidic cationic resin 50g that model is D001, add the 90% ethanol of 100ml and carry out conversion under the room temperature condition, obtain glycyrrhizic acid solution after conversion is completed, add the ammonium acetate of 8g and 2g of formic acid solution, continuously stirred for 0.5-1h, transferred to room temperature for s...

Embodiment 3

[0042] Embodiment 3: after getting crushed and sieved (60-80 order), glycyrrhizic acid coarse powder 100g, add the 90% ethanol of 1200ml and extract at 35 ℃ of temperature for 3 hours, extract solution adds the ammonium formate of 10g and 5g at the same temperature After stirring for a while, the acetic acid solution was transferred to room temperature for stirring and crystallization, and filtered after 4 hours to obtain the crude product of monoammonium glycyrrhizinate. Get the crude product of monoammonium glycyrrhizic acid salt, add the strong acid cationic resin 40g that model is LSI-010, add the 95% ethanol of 80ml and carry out conversion under the room temperature condition, obtain glycyrrhizic acid solution after conversion is completed, add the formic acid of 10g at 35 ℃ Ammonium and 5g of acetic acid solution, after stirring for a period of time, transferred to room temperature for stirring and crystallization, filtered after 4 hours, and dried at 70°C for 5h to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com