Method for increasing the yield of monosaccharide production in agar by using buffer pretreatment

A pretreatment and buffer technology, applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve the problems of expensive, low production yield of monosaccharides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Production of Recombinase

[0057] Using pET-21a as a vector and Aga50D (EMBL ID: ADB81904), NABH (EMBL ID: ADB81917) and ABG (EMBL ID: CP003241) enzymes in Escherichia coli (E.coli) BL21 (DE3 ) to produce recombinant proteins. Colonies obtained by transforming host cells plated on solid medium supplemented with 50 μg / mL ampicillin were re-inoculated on Luria broth (LB) plates containing 50 μg / mL ampicillin, and then incubated at 37 °C and 220 rpm 12 hours (20 mL×2) for seed culture. Then, the cells were seeded in two 3L Erlenmeyer flasks each containing 1L LB broth, cultured with shaking under the same conditions for 3 hours (OD=0.8) and cooled on ice for 1 hour, and then added 0.1mM IPTG to inoculate at 16 Expression was induced at 120 rpm for 12 hours. The resulting culture was centrifuged (6000rpm, 4°C, 15 minutes) to collect the cells, and then the resulting cells were suspended in 20mM Tris buffer (Tris-HCl, 1M NaCl pH8), lysed with a sonicator, and centrifuge...

Embodiment 2

[0058] pretreatment agar with buffer solution

[0059] In order to compare glycation after agar pretreatment with 20 mM Tris-HCl (pH 7.5) buffer and agarose pretreatment with 3% acetic acid, two types of pretreatment were performed. 1 g (5%) agar was mixed with 20 mL of 20 mM Tris-HCl (pH 7.5) buffer at 170 °C for 5, 10, 15 and 20 min, and 1.4 g (7%) agarose was mixed with 20 mL of 3% acetic acid And microwave treatment at 130° C. for 30 minutes to carry out hydrolysis. Then, the resulting product was neutralized to pH 7 using 1M NaOH, and the final concentration of agar and agarose was adjusted to 4.5% using distilled water.

[0060] Table 1 shows the final production yields of 3,6-anhydro-L-galactose and D-galactose, the amount of HMF produced and the amount of neutralizing solvent according to the pretreatment conditions and initial substrates.

[0061] [Table 1]

[0062]

[0063]

[0064]As shown in Table 1, in agar pretreatment (170°C, 10 minutes) with 20 mM Tri...

Embodiment 3

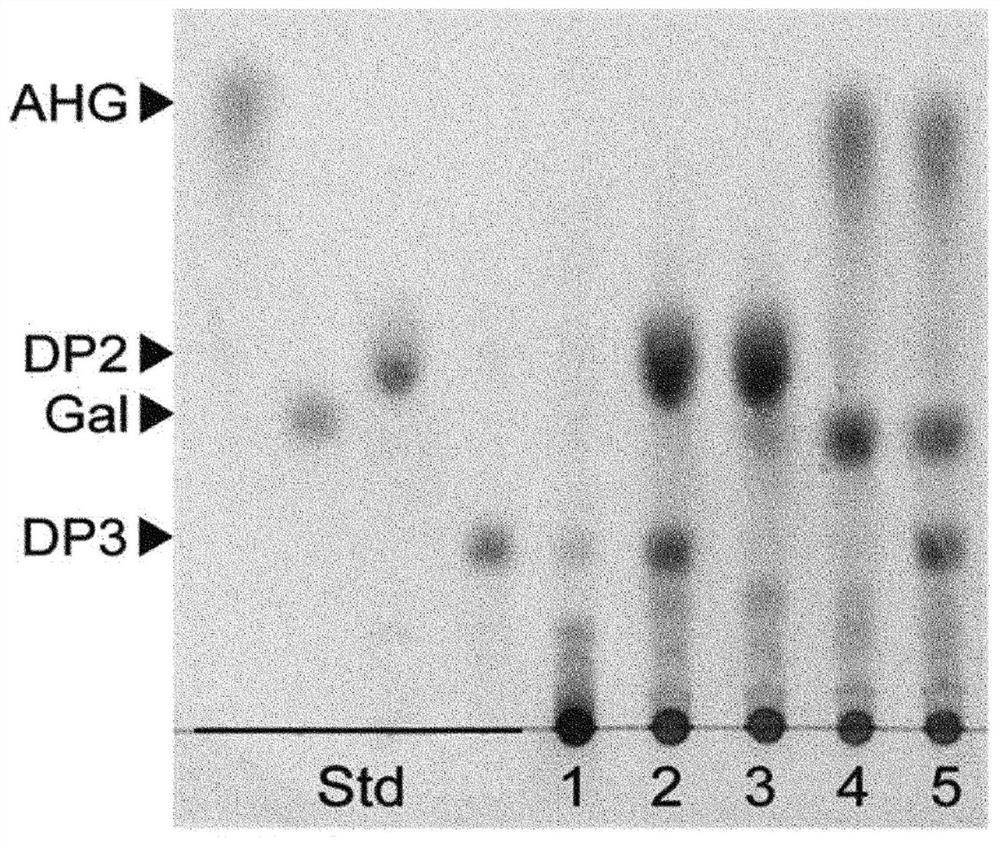

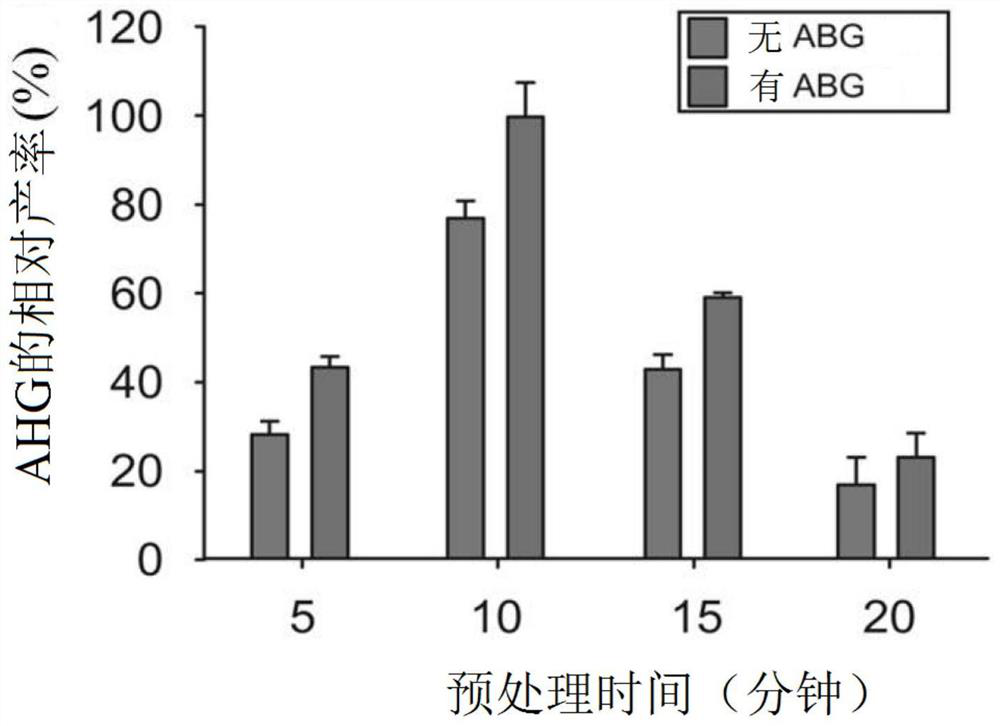

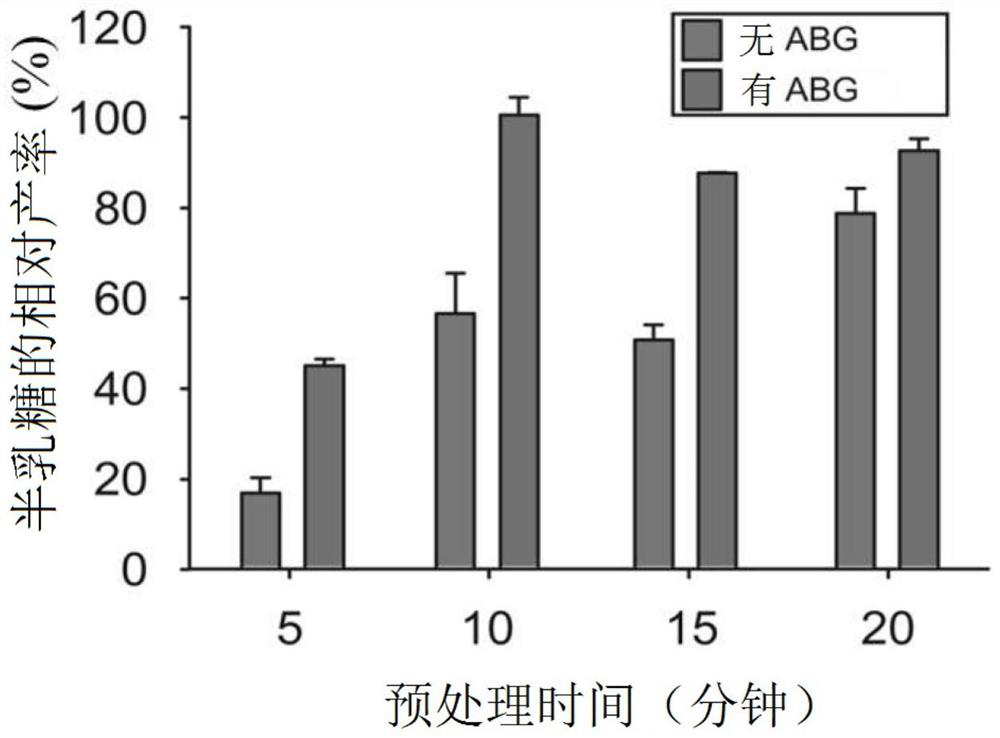

[0065] with the enzymatic saccharification method of the pretreatment product of buffer pretreatment

[0066] 5 mL of the pretreated product of Example 2 was reacted with the enzymes Aga50D (19.0 U), ABG (4.6 U) and NABH (14.5 U) prepared in Example 1 in sequence. Each enzyme was reacted at 30°C for 12 hours and then inactivated in boiling water for 5 minutes. To confirm the effect of ABG in this process, only two enzymes such as Aga50D and NABH (excluding ABG) were reacted under the same conditions as described above.

[0067] Final reaction products such as 3,6-anhydro-L-galactose and D-galactose were quantified by HPLC (Agilent 1100, Agilent, Waldbronn, Germany) using an Aminex HPX-87H column (Bio-Rad, Richmond, CA). The mobile phase was 40% (v / v) acetonitrile (CH 3 CN) in water and analyzed at 65 °C and a flow rate of 0.5 mL / min.

[0068] The unit of Aga50D is defined as the amount of agarobiose produced from agarose in 20 mM Tris-HCl buffer (pH 7) at 30° C. for 1 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com