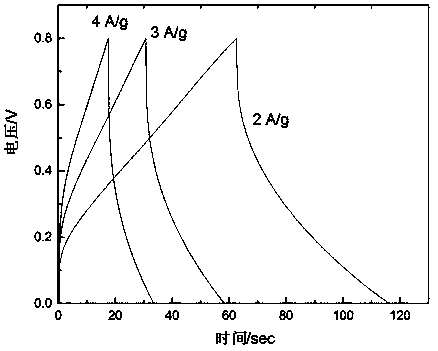

A kind of preparation method of nio@graphene fiber supercapacitor electrode material

A graphene fiber, supercapacitor technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as low specific capacitance value, limited potential applications, low energy density of capacitor devices, etc., to improve specific capacitance. , High specific capacity, excellent specific capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) the graphene oxide aqueous dispersion is centrifuged and concentrated, and then ultrasonically treated for 20min, thereby obtaining the graphene oxide spinning solution;

[0028] (2) Use a syringe pump to inject the graphene oxide spinning solution into the 2 In the coagulation bath composed of / ethanol solution, after immersion in the coagulation bath for 30min, the obtained fiber was repeatedly washed 3 times with deionized water and ethanol, and the residual coagulation solution was washed away, so as to obtain graphene oxide fiber and collect it on the support , drying the collected fibers at high temperature under vacuum conditions;

[0029] (3) The graphene oxide fibers were reduced in hydroiodic acid at 120°C for 8h, and then 2 / Ar (volume ratio is 1:1) under the reducing atmosphere of 1000 ° C thermal reduction, natural cooling to room temperature and then take out the fiber, so as to prepare graphene fiber;

Embodiment 2

[0033] (1) the graphene oxide aqueous dispersion is centrifuged and concentrated, and then ultrasonically treated for 30min, thereby obtaining the graphene oxide spinning solution;

[0034] (2) Use a syringe pump to inject the graphene oxide spinning solution into the 2 In the coagulation bath composed of / ethanol solution, after immersing in the coagulation bath for 20min, the obtained fiber was repeatedly washed 3 times with deionized water and ethanol, and the residual coagulation solution was washed away, so as to obtain graphene oxide fiber and collect it on the support , drying the collected fibers at high temperature under vacuum conditions;

[0035] (3) The graphene oxide fibers were reduced in hydroiodic acid at 90°C for 12h, and then 2 / Ar (volume ratio is 1:4) under the reducing atmosphere of 1000 ° C thermal reduction, natural cooling to room temperature and then take out the fiber, so as to prepare the graphene fiber;

Embodiment 3

[0039] (1) the graphene oxide aqueous dispersion is centrifuged and concentrated, and then ultrasonically treated for 30min, thereby obtaining the graphene oxide spinning solution;

[0040] (2) Use a syringe pump to inject the graphene oxide spinning solution into the 2 In the coagulation bath composed of / ethanol solution, after immersion in the coagulation bath for 30min, the obtained fiber was repeatedly washed 5 times with deionized water and ethanol, and the residual coagulation solution was washed away, so as to obtain graphene oxide fiber and collect it on the support , drying the collected fibers at high temperature under vacuum conditions;

[0041] (3) The graphene oxide fibers were reduced in hydroiodic acid at 120°C for 12h, and then 2 / Ar (volume ratio: 1:2) under a reducing atmosphere of 1000 ° C thermal reduction, natural cooling to room temperature and then take out the fiber, so as to prepare graphene fiber;

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com