Fragile tag preventing from edge warping and preparation method thereof

A label and frangible layer technology, which is applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of small peeling force, damage to the label structure, etc., to improve the bonding fastness, enhance the damage effect, and combine Simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Making HF anti-warping and fragile electronic tags

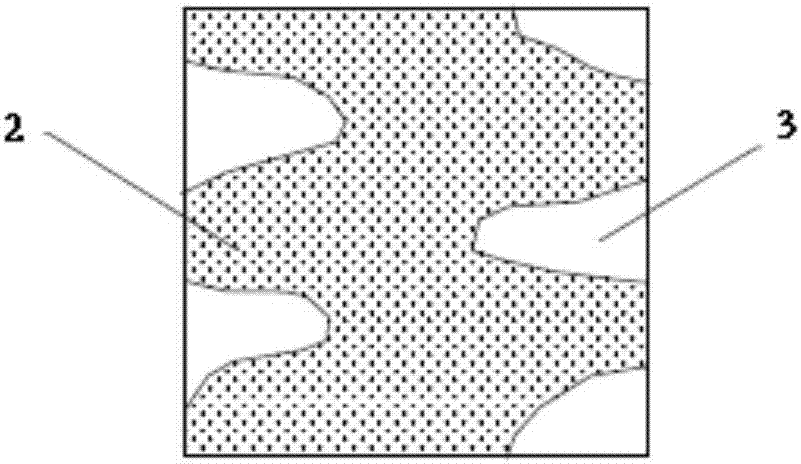

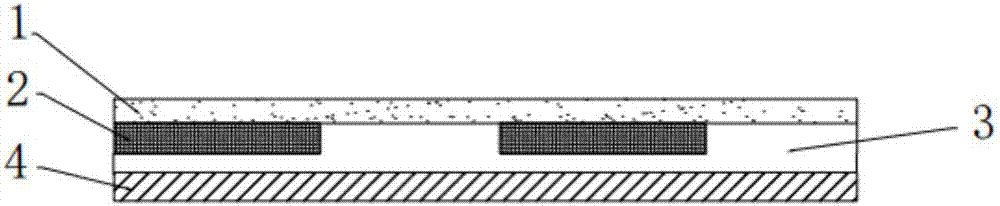

[0030] see Figure 4 , select 38μm PET substrate, on the side whose surface tension is less than 40 dynes, apply acrylic resin light peeling coating to form a peeling force of 0.3-0.8N light peeling fragile area, and then compound 30μm aluminum foil to form a peeling force> In the 3.5N non-fragile area, the HF antenna is etched on the aluminum foil, and the bridge is etched on the other side of the PET substrate with 10μm aluminum foil and riveted. The non-fragile area is randomly scattered on the PET base material to ensure that there is more than one non-fragile area on the edge of the label in the bending direction, and the non-fragile area is mainly distributed on the edge of the label, so that the antenna processing does not need to track the non-fragile area. The minimum width of the broken area is greater than 2mm, and the jump distance of the adjacent non-fragile area is smaller than the size of th...

Embodiment 2

[0031] Example 2: Making UHF anti-warping and fragile electronic tags

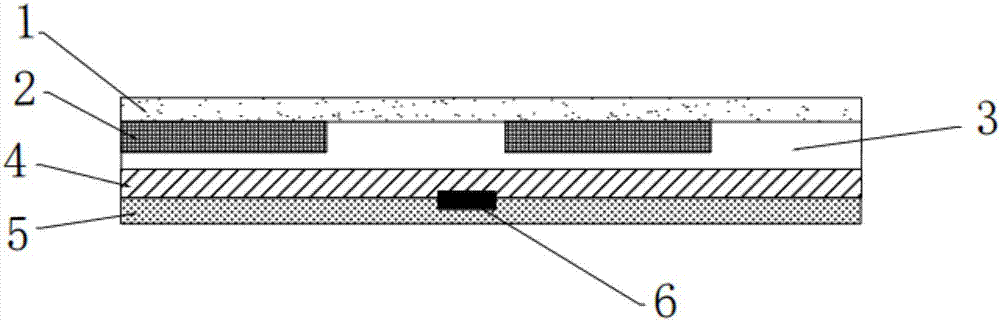

[0032] see Figure 5 , select a 50μm PET substrate, and apply an acrylic resin light peeling coating on the side whose surface tension is less than 42 dynes to form a peeling force of 0.5-1N light peeling fragile area, and then corona the coating surface of the PET substrate Composite 10μm aluminum foil to form a non-fragile area with a peeling force > 4N, and then etched UHF antenna, the non-fragile area is regularly arranged on the PET substrate, the chip pad is set in the non-fragile area, and the closed loop of the antenna spans the fragile area and the non-fragile area; then bind the UHF high-frequency chip, cover the chip surface with a high-temperature-resistant self-adhesive with a peel strength of 10N, and die-cut the substrate after the chip is bound UHF fragile electronic tags. The label is further attached to the surface of the curved glass, and the large peeling force in the non-fragile area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com