Welding method of duplex stainless steel thin plate

A duplex stainless steel and welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of non-fusion, slow welding speed, and low welding efficiency, so as to improve welding speed and welding efficiency and solve unforeseen problems. fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

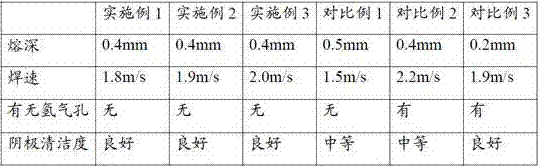

Embodiment 1

[0030] A method for welding duplex stainless steel sheets, comprising the following steps:

[0031] 1) Process the groove on the duplex stainless steel plate, butt weld after the groove processing is completed;

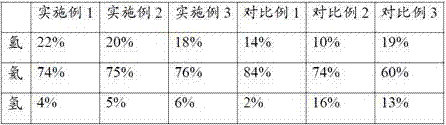

[0032] 2) Argon-helium-hydrogen ternary gas shielded argon arc welding is used, and thorium tungsten electrode and duplex stainless steel welding wire W22 93NL are used for welding. The volume fraction ratio of the ternary mixed gas used is 22% argon, 74% helium, Hydrogen 4%.

Embodiment 2

[0034] A method for welding duplex stainless steel sheets, comprising the following steps:

[0035] 1) Process the groove on the duplex stainless steel plate, butt weld after the groove processing is completed;

[0036] 2) Argon-helium-hydrogen ternary gas shielded argon arc welding is used, and thorium tungsten electrode and duplex stainless steel welding wire W22 93NL are used for welding. The volume fraction ratio of the ternary mixed gas used is 20% argon and 75% helium. Hydrogen 5%.

Embodiment 3

[0038] A method for welding duplex stainless steel sheets, comprising the following steps:

[0039] 1) Process the groove on the duplex stainless steel plate, butt weld after the groove processing is completed;

[0040] 2) Argon-helium-hydrogen ternary gas shielded argon arc welding is used, and thorium tungsten electrode and duplex stainless steel welding wire W22 93NL are used for welding. The volume fraction ratio of the ternary mixed gas used is 18% argon and 76% helium. Hydrogen 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com