Method for automatically controlling cooling capacity of distillation tower top

A rectifying tower and tower top technology, which is applied in the field of automatic control of the cooling capacity of the rectifying tower tower top, can solve the problem of affecting the gas-liquid balance of the rectifying tower, the product quality failing to meet the production requirements, and the difficulty in determining the liquid volume under the tray, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

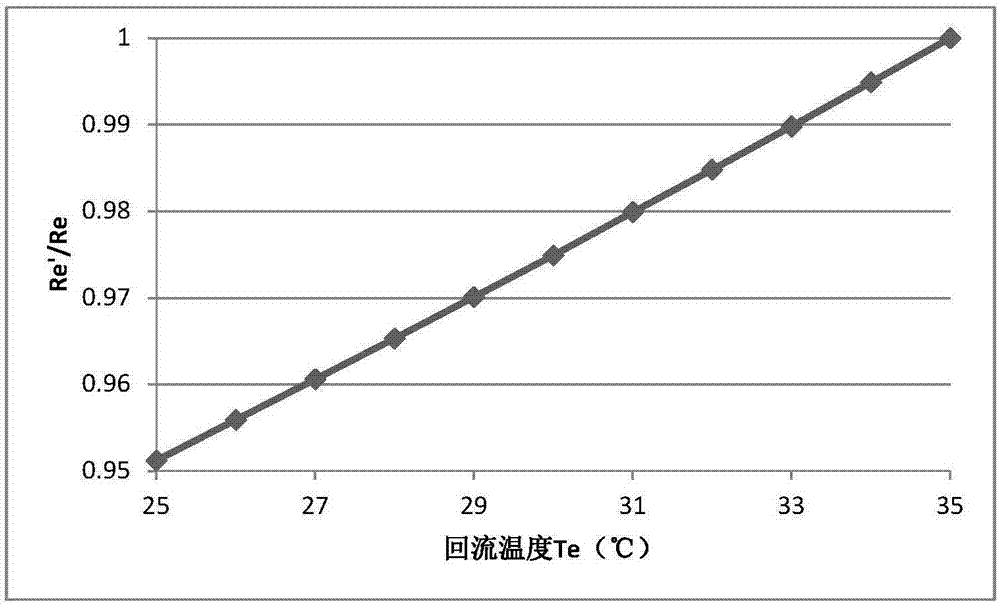

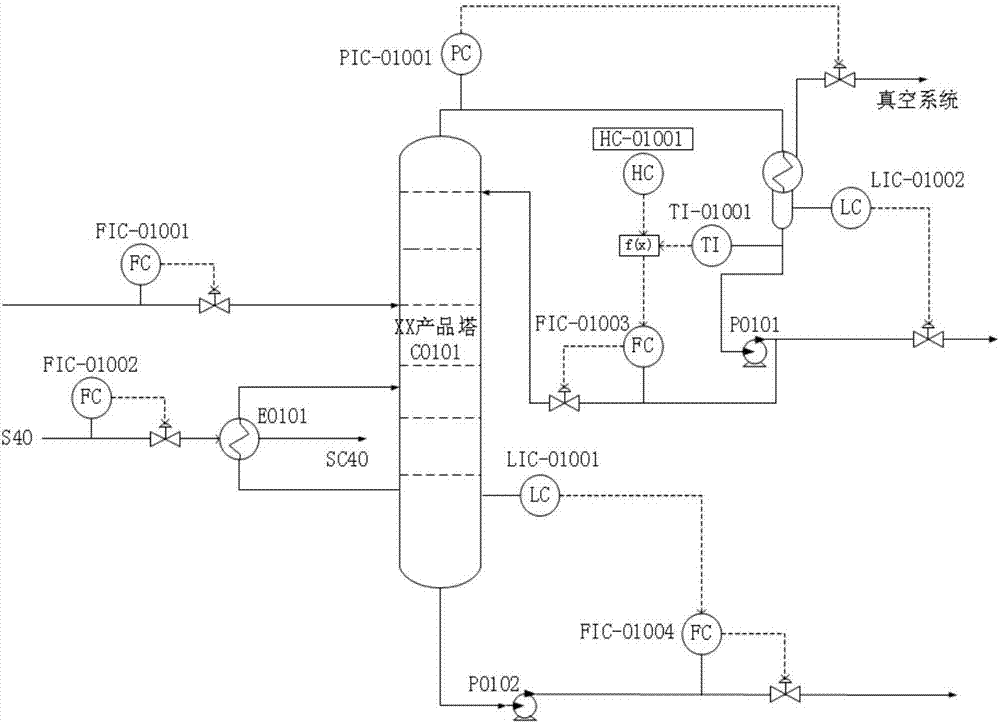

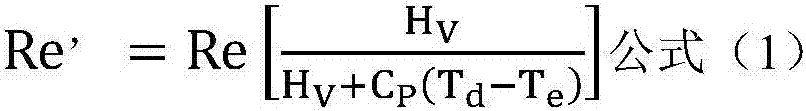

Embodiment 1

[0051] A product tower in a chemical plant is used for the separation of products and heavy components. The tower kettle uses S40 as the heat source. Due to the influence of ambient temperature, the temperature of the condensing circulating water varies greatly in winter, summer, and day and night. The range of variation is usually 25-31°C. The reflux temperature at the top of the product tower fluctuates in the range of 25-34°C, the reflux is relatively large, and the steam consumption in the tower bottom is 3.6t / h. For this reason, design and implement according to the method of automatic control of cooling capacity at the top of the rectification tower in this patent, determine the reference working conditions as the reflux temperature Td is 34°C, the reflux flow Re is 5.5t / h, use tools to collect the rectification tower The temperature Te of the top reflux liquid, the pressure P at the top of the tower and the composition X parameters of the top reflux liquid, and the heat ...

Embodiment 2

[0054] A refining tower in a chemical plant is used for the separation of products and impurities. The tower kettle uses S15 as the heat source, and the top of the tower uses an air cooler to condense. Due to the large weather changes in the north, the temperature of the reflux liquid varies from 20°C to 80°C, which means The actual reflux cooling capacity varies greatly, bringing up to 26 operations per shift, and the average steam consumption in the tower kettle is 15t / h. For this reason, design and implement according to the method of automatic control of cooling capacity at the top of the rectification tower in this patent, determine the reference working conditions as the reflux temperature Td is 59 ° C, the reflux flow Re is 13t / h, use tools to collect the top of the rectification tower Reflux liquid temperature Te, tower top pressure P and tower top reflux liquid composition X parameters, and the heat of vaporization Hv of the reflux liquid is determined to be 1330.68kJ / ...

Embodiment 3

[0056] A light removal tower in a chemical plant is used for the separation of products and light components. The tower kettle uses S10 as the heat source. The top of the tower uses an air cooler and circulating water for secondary condensation. Since the circulating water and air have a temperature difference between day and night, the The temperature of the reflux liquid varies from 30°C to 78°C, which means that the actual cooling capacity of the reflux varies greatly, resulting in an operation volume of up to 32 times / shift, and the average steam consumption in the tower bottom is 8t / h. For this reason, design and implement according to the method of automatic control of cooling capacity at the top of the rectification tower in this patent, determine the reference working conditions as the reflux temperature Td is 65 ° C, the reflux flow Re is 10t / h, and use tools to collect the top of the rectification tower Reflux liquid temperature Te, tower top pressure P and tower top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com