Superconducting magnetic fluid flowmeter internally provided with grilles

A technology of fluid flow and superconducting magnetism, applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effect, temperature measurement of moving fluid, etc. Fluid potential, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

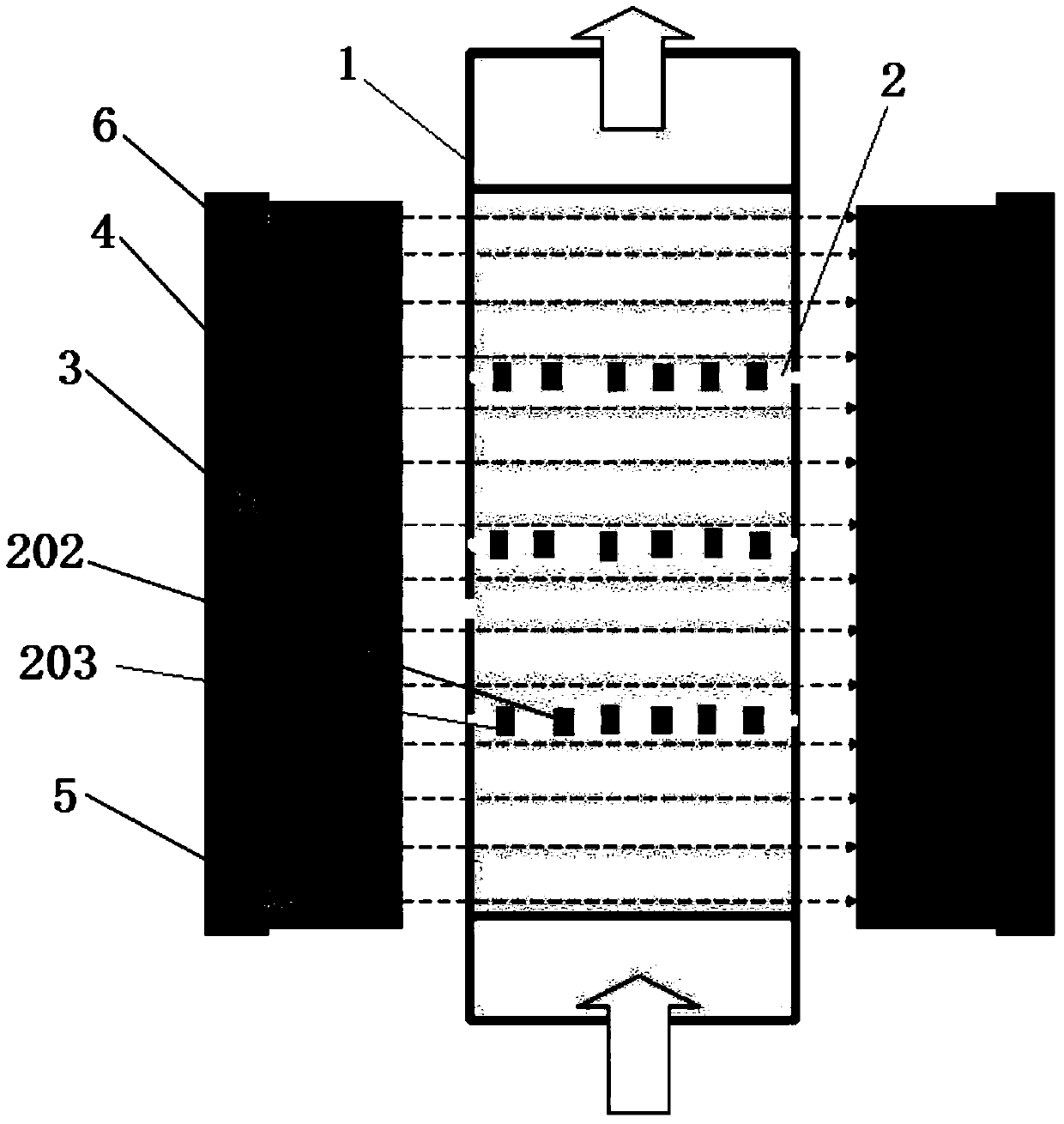

[0028] A superconducting magnetic fluid flowmeter with a built-in grid includes a pipeline 1 and a magnetic field, and the pipeline 1 is perpendicular to the direction of the magnetic field. The pipe is perpendicular to the direction of the magnetic field means that the flow direction of the metal fluid in the pipe is perpendicular to the direction of the magnetic field. The cross-section of the pipe is circular. Take the axial direction of the pipe as the longitudinal direction, and the direction perpendicular to the axial direction as the transverse direction.

[0029] In some embodiments, the duct is polygonal in cross-section.

[0030] grille

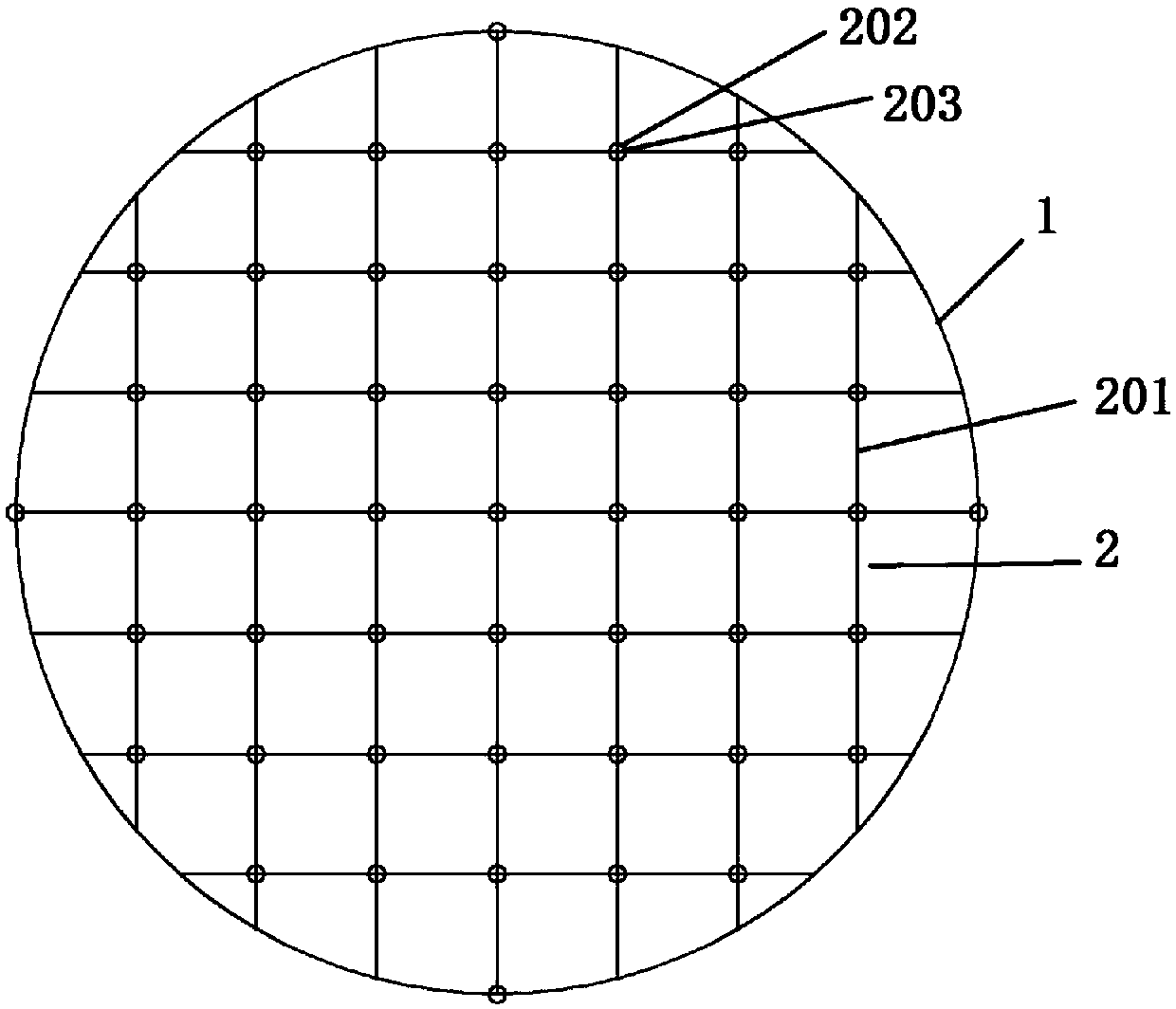

[0031] Such as figure 1 with figure 2 As shown, the pipeline 1 is provided with a grid 2, the grid 2 is fixed on the inner wall of the pipeline 1, the plane where the grid 2 is located is perpendicular to the axis of the pipeline 1, and the grid 2 includes a plurality of partitions 201; A plurality of detection electrodes 20...

Embodiment 2

[0040] In this embodiment, except that the magnetic field is generated by superconducting magnetic poles, other structures can adopt the structures described in the above embodiments.

[0041] superconducting pole

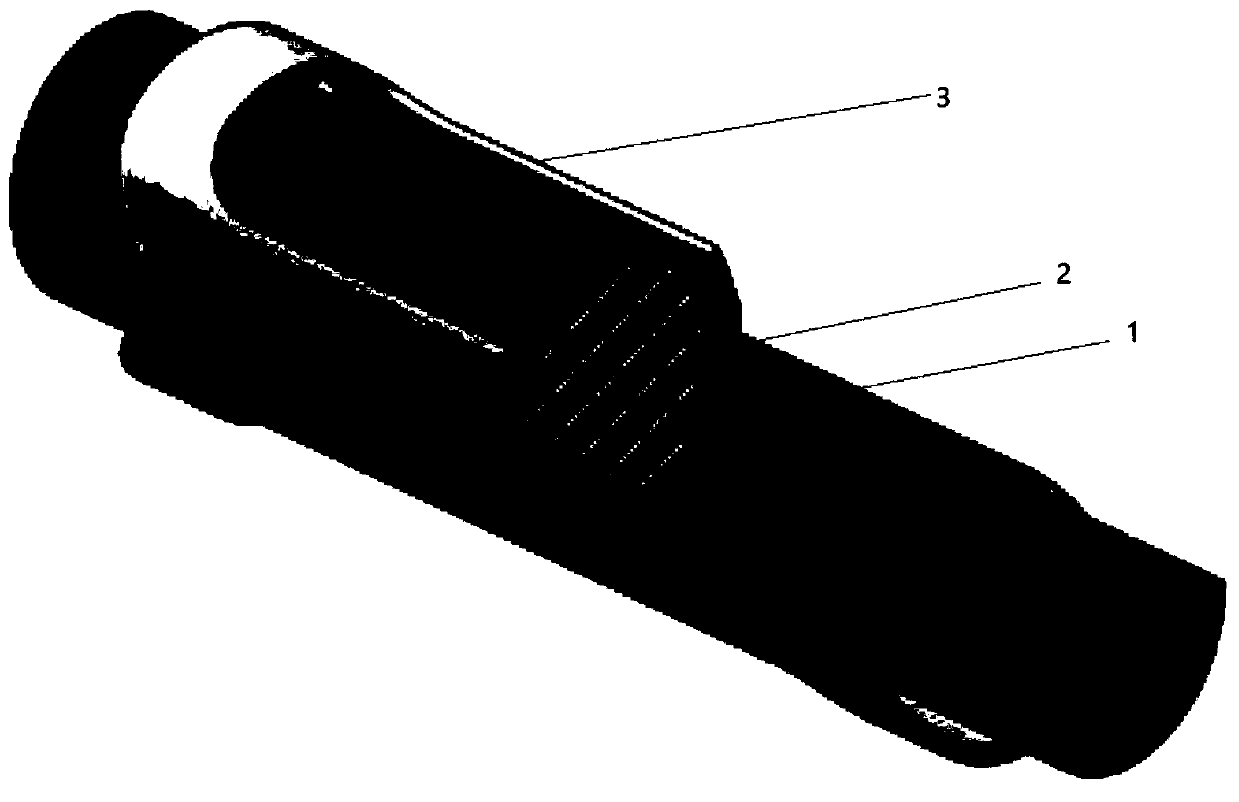

[0042] Such as figure 1 As shown, the magnetic field is generated by the superconducting magnetic pole 3, which is in the shape of a cylinder, and the pipeline 1 is located in the cylinder surrounded by the superconducting magnetic pole.

[0043] In some embodiments, superconducting magnetic poles are located on both sides of the tube.

[0044] The superconducting pole 3 is surrounded by a Dewar 4 filled with cooling medium. The Dewar filled with cooling medium maintains the low-temperature state of the superconducting magnetic poles to ensure that the superconducting magnetic poles can generate a magnetic field stably. The cooling medium is liquid nitrogen. In some embodiments, the cooling medium is liquid helium.

[0045] A water jacket 5 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com