Hard high-protein less-sugar auricularia fuscosuccinea biscuit and preparation method thereof

A technology of tough biscuit and agaric fungus, which is applied in bakery food, dough processing, baking and other directions, can solve the problems of biscuit that have not been publicized, put forward polysaccharides, etc., achieve scientific and reasonable product formula, reduce food intake, and simple and easy processing method row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

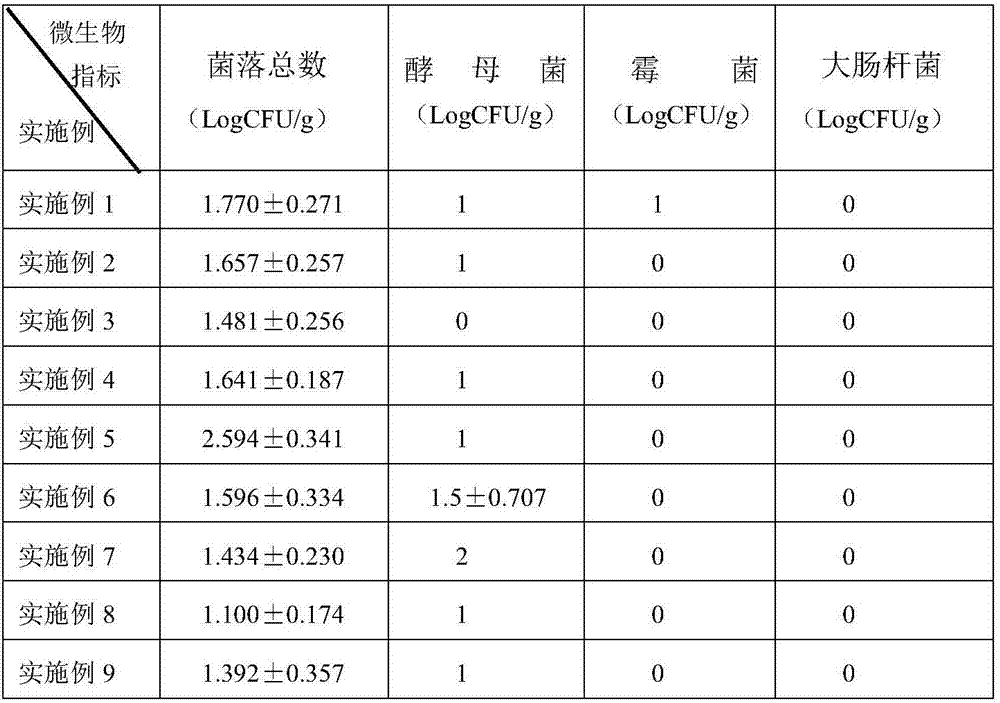

Examples

Embodiment 1

[0018] The high-protein and low-sugar corn fungus tough biscuit of this embodiment is made according to the following formula and steps:

[0019] Preparation of Auricularia residues: Select Auricularia raw materials without impurities and rot, dry them at 45°C, and use a universal high-speed pulverizer to pulverize them to powder, pass through a 60-mesh sieve to obtain Auricularia powder; weigh the Auricularia powder, and Soak overnight at a liquid ratio of 1:40, heat and extract in a water bath at 90°C for 2 hours, centrifuge at 6000r / min for 20 minutes, collect the extract and residues, extract twice and combine the extracts for further extraction of polysaccharides and Separation and purification, collecting the extraction residue and using a homogenizer to whip it evenly before making biscuits;

[0020] Preparation of high-protein and low-sugar jade fungus biscuits:

[0021] (1) Kneading dough: Weigh 200g wheat flour, 40g jade fungus residue, 10g corn oil, 10g butter, 20g...

Embodiment 2

[0027] The high-protein and low-sugar corn fungus tough biscuit of this embodiment is made according to the following formula and steps:

[0028] Preparation of Auricularia residues: Select Auricularia raw materials without impurities and rot, dry them at 45°C, and use a universal high-speed pulverizer to pulverize them to powder, pass through an 80-mesh sieve to obtain Auricularia powder; weigh the Auricularia powder, and Soak overnight at a liquid ratio of 1:60, heat and extract in a water bath at 90°C for 2 hours, centrifuge at 6000r / min for 20 minutes, collect the extract and the residue, extract twice and combine the extracts for further extraction of polysaccharides and Separation and purification, collecting the extraction residue and using a homogenizer to whip it evenly before making biscuits;

[0029] Preparation of high-protein and low-sugar jade fungus biscuits:

[0030] (1) Kneading dough: Weigh 200g wheat flour, 40g jade fungus residue, 20g corn oil, 10g butter,...

Embodiment 3

[0036] The high-protein and low-sugar corn fungus tough biscuit of this embodiment is made according to the following formula and steps:

[0037] Preparation of Auricularia residues: Select Auricularia raw materials without impurities and rot, dry them at 45°C and use a universal high-speed pulverizer to pulverize them to powder, pass through a 100-mesh sieve to obtain Auricularia powder; weigh the Auricularia powder, Soak overnight at a liquid ratio of 1:80, heat and extract in a water bath at 90°C for 2 hours, centrifuge at 6000r / min for 20 minutes, collect the extract and residues, extract twice and combine the extracts for further extraction of polysaccharides and Separation and purification, collecting the extraction residue and using a homogenizer to whip it evenly before making biscuits;

[0038] Preparation of high-protein and low-sugar jade fungus biscuits:

[0039](1) Kneading dough: Weigh 200g wheat flour, 40g jade fungus residue, 20g corn oil, 20g butter, 60g xyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com