A manufacturing process of double 85 anti-pid polycrystalline solar cells

A technology of solar cells and manufacturing process, which is applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of power reduction of cells and components, and achieve the effects of extended component life, good product performance, and convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

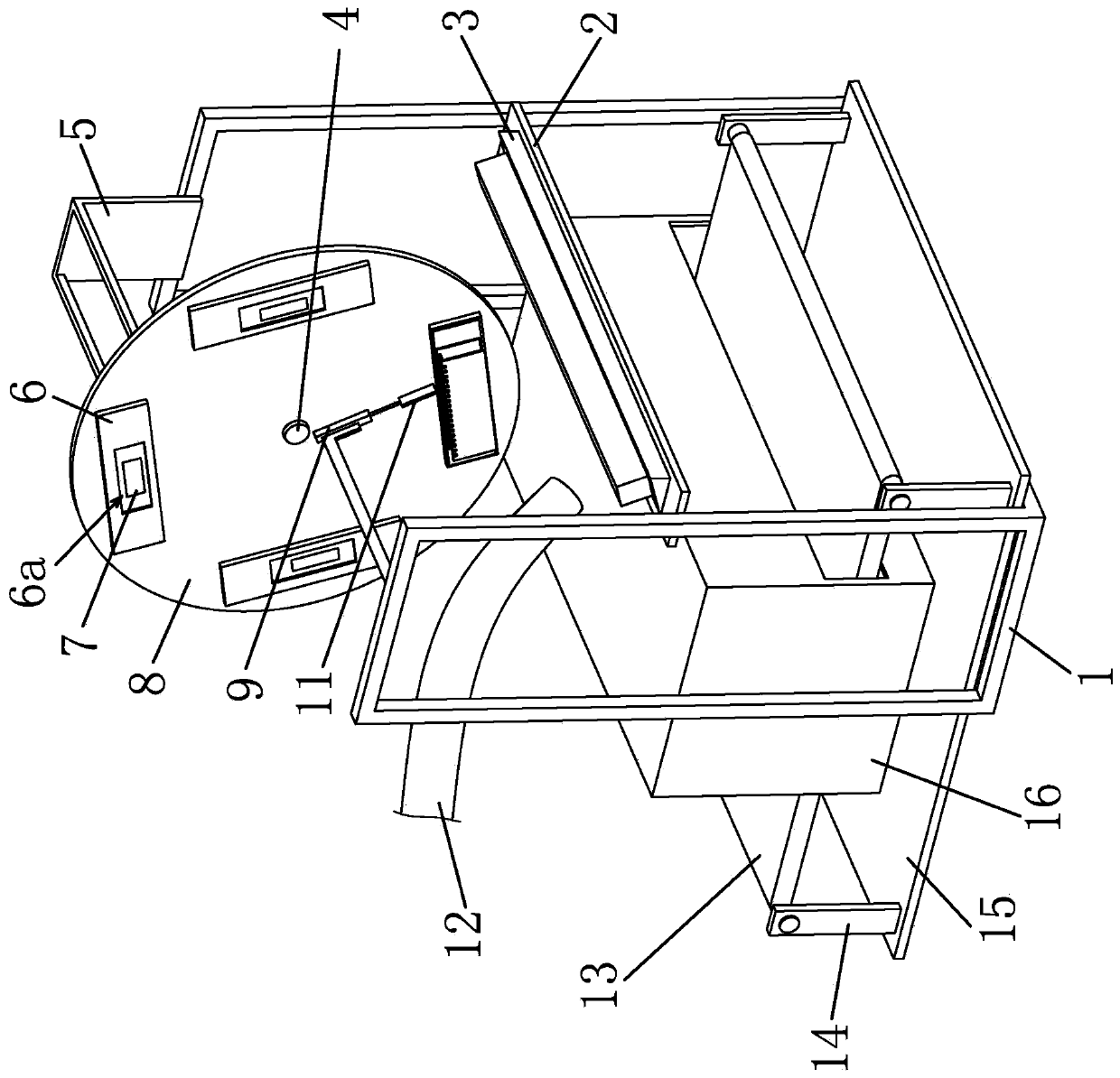

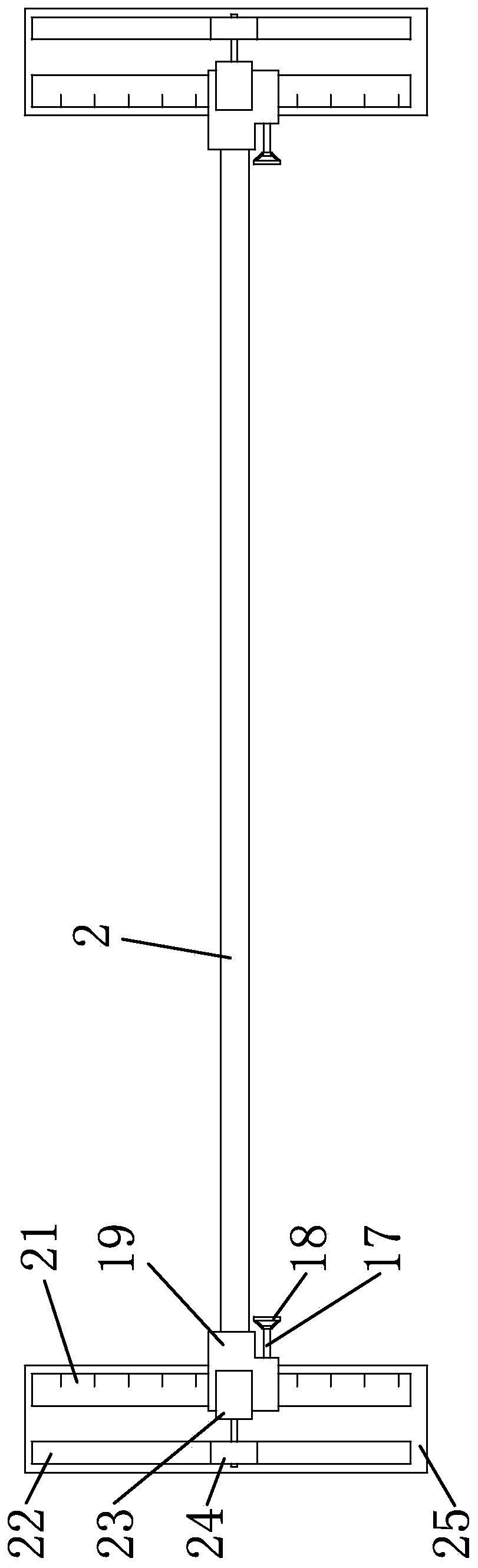

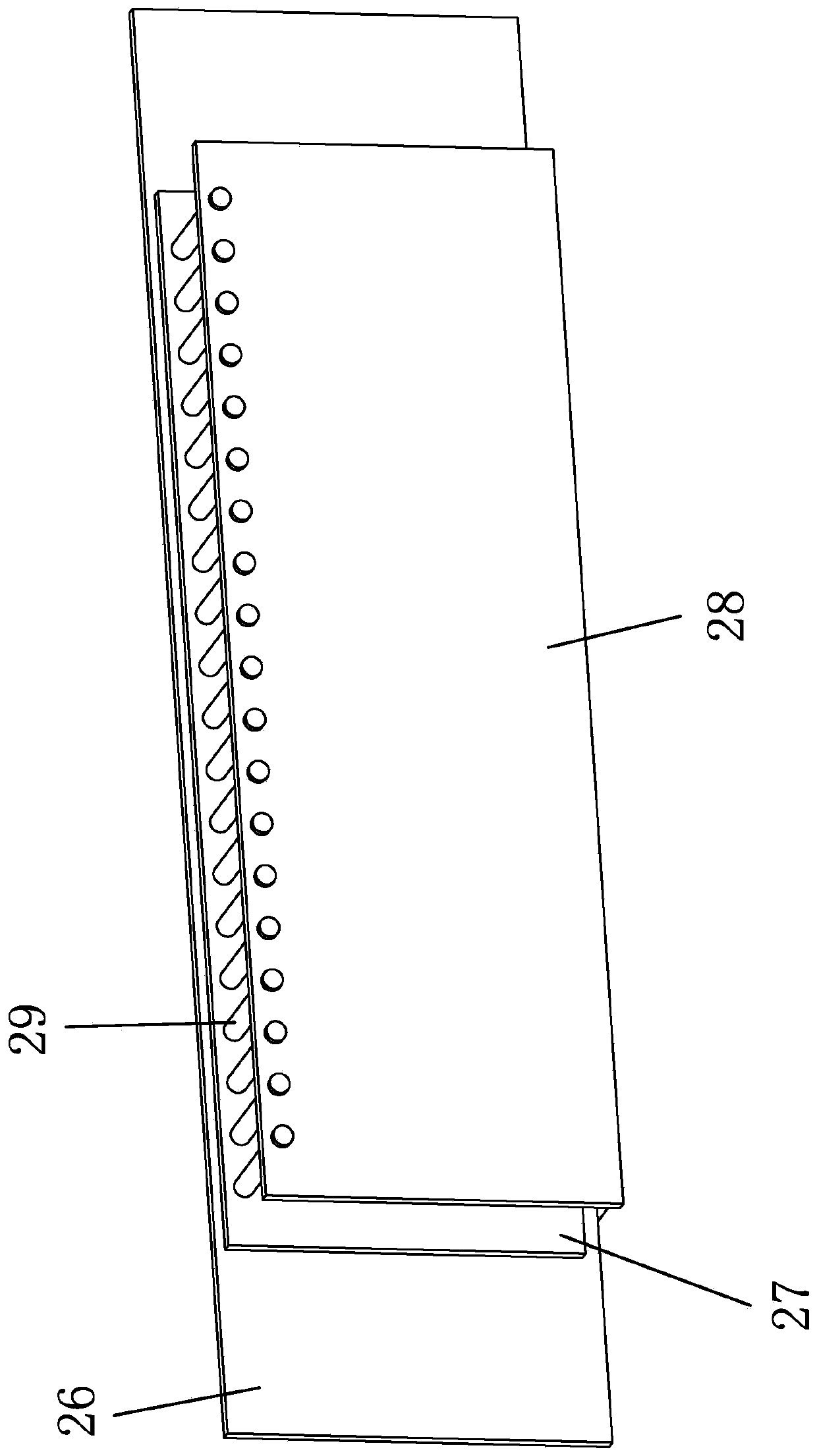

Image

Examples

Embodiment 1

[0072] The manufacturing process of the double 85 anti-PID polycrystalline solar cells comprises the following steps:

[0073] a. The crystalline silicon wafer after cleaning, diffusion, and etching will generate a layer of 1nm SiO on the surface of the crystalline silicon wafer through an ozone generator 2 Oxide film;

[0074] b. Put the crystalline silicon wafer completed in step a on the graphite boat through the loading and unloading system, and put it into the tubular PECVD for pre-deposition. The PECVD parameters are set as: ammonia gas flow rate 4.5-5.0slm, radio frequency power 5000-6000wart , time 0-60s;

[0075] c. Deposit the crystalline silicon wafer completed in step b by tubular PECVD to obtain a high-refractive-index silicon nitride anti-reflection film with a first-layer refractive index of 2.30-2.35. The PECVD parameters are set to: ammonia gas flow rate 4.5- 5.0slm, silane flow rate 1000-1100sccm, pressure 1650-1750mTor, RF power 5500-6500wart, switching ti...

Embodiment 2

[0087] The manufacturing process of the double 85 anti-PID polycrystalline solar cells comprises the following steps:

[0088] a. After cleaning the textured, diffused and etched crystalline silicon wafer, generate a layer of 2nm SiO on the surface of the crystalline silicon wafer through an ozone generator 2 Oxide film;

[0089] b. Put the crystalline silicon wafer completed in step a on the graphite boat through the loading and unloading system, and put it into the tubular PECVD for pre-deposition. The PECVD parameters are set as: ammonia gas flow rate 4.5-5.0slm, radio frequency power 5000-6000wart , time 0-60s;

[0090] c. Deposit the crystalline silicon wafer completed in step b by tubular PECVD to obtain a high-refractive-index silicon nitride anti-reflection film with a first-layer refractive index of 2.30-2.35. The PECVD parameters are set to: ammonia gas flow rate 4.5- 5.0slm, silane flow rate 1000-1100sccm, pressure 1650-1750mTor, RF power 5500-6500wart, switching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com