Quantitative optimization method for pyrogenic-process copper smelting slag form

A technology of pyrometallurgy and quantitative optimization, which is applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as high economic cost, heavy workload, and increased mechanical inclusions, so as to shorten the work process, Realize the effect of directional regulation and reduce the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The main components in the slag phase of a copper smelter are: FeO 24.90%, SiO 2 34.88%, CaO 5.00%, MgO 2.65%, Al 2 o 3 8.93%, Fe 3 o 4 14.93%.

[0039] The method for quantitatively optimizing the slag type of the pyrometallurgy furnace slag comprises the following steps:

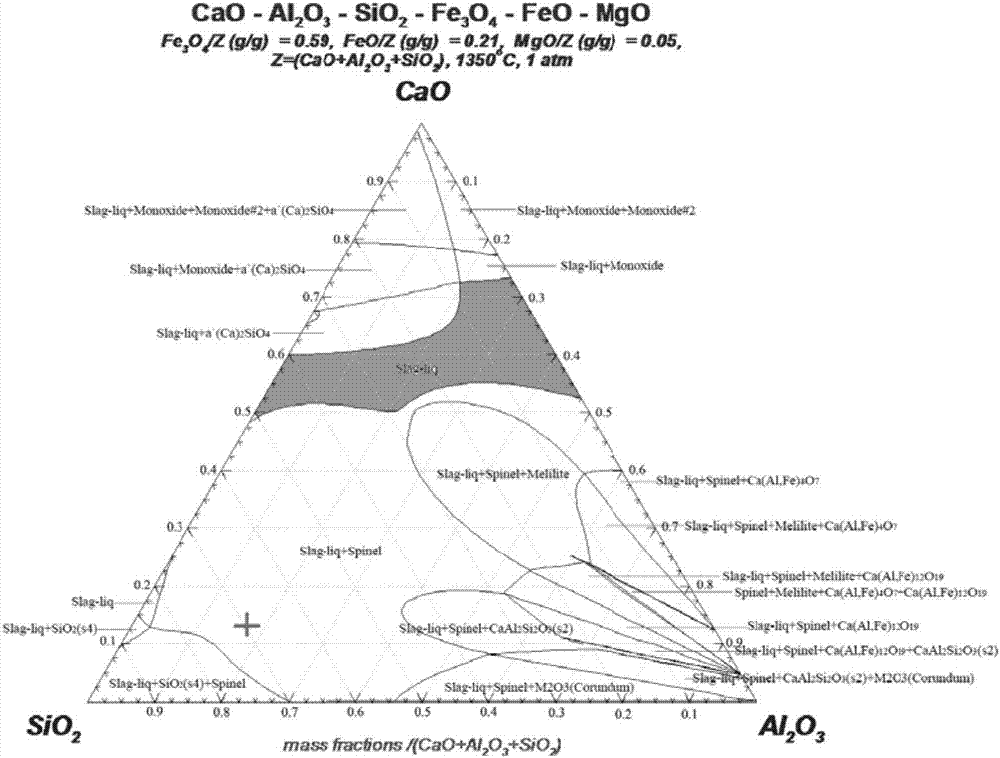

[0040] Step 1. First, according to the slag composition characteristics of the copper smelting slag process, according to the percentage content of each component in the slag phase and the corresponding physical and chemical properties in the silicate system, determine the basic smelting slag system. From the slag of a copper smelting plant mentioned above , select the basic slag system of the slag phase as Al 2 o 3 -SiO 2 -CaO,;

[0041] Step 2, CaO, SiO in the slag system 2 、Al 2 o 3 As a variable, the percentage content of the remaining components is used as a fixed amount (Fe 3 o 4 , FeO and MgO are fixed quantities), according to the multivariate and multiphase equilibrium calcul...

Embodiment 2

[0066] The main components in the slag phase of a copper smelter are: FeO 8.22%, SiO 2 26.79%, CaO 5.01%, MgO2.03%, Al 2 o 3 6.90%, Fe 3 o 4 23.03%.

[0067] The method for quantitatively optimizing the slag type of the pyrometallurgy furnace slag comprises the following steps:

[0068] Step 1. First, according to the slag composition characteristics of the copper smelting slag process, according to the percentage content of each component in the slag phase and the corresponding physical and chemical properties in the silicate system, determine the basic smelting slag system. From the slag of a copper smelting plant mentioned above , select the basic slag system of the slag phase as Al 2 o 3 -SiO 2 -CaO,;

[0069] Step 2, CaO, SiO in the slag system 2 、Al 2 o 3 As a variable, the percentage content of the remaining components is used as a fixed amount (Fe 3 o 4 , FeO and MgO are fixed quantities), according to the multivariate and multiphase equilibrium calcula...

Embodiment 3

[0093] The main components in the slag phase of a copper smelter are: FeO 20.32%, SiO 2 37.70%, CaO 5.03%, MgO2.79%, Al 2 o 3 9.21%, Fe 3 o 4 11.98%.

[0094] The method for quantitatively optimizing the slag type of the pyrometallurgy furnace slag comprises the following steps:

[0095] Step 1. First, according to the slag composition characteristics of the copper smelting slag process, according to the percentage content of each component in the slag phase and the corresponding physical and chemical properties in the silicate system, determine the basic smelting slag system. From the slag of a copper smelting plant mentioned above , select the basic slag system of the slag phase as Al 2 o 3 -SiO 2 -CaO,;

[0096] Step 2, CaO, SiO in the slag system 2 、Al 2 o 3 As a variable, the percentage content of the remaining components is used as a fixed amount (Fe 3 o 4 , FeO and MgO are fixed quantities), according to the multivariate and multiphase equilibrium calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com