Reinforced type prefabricated steel bar concrete shear wall, structural system and construction method thereof

A reinforced concrete, reinforced technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor ductility, long construction period, large construction volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

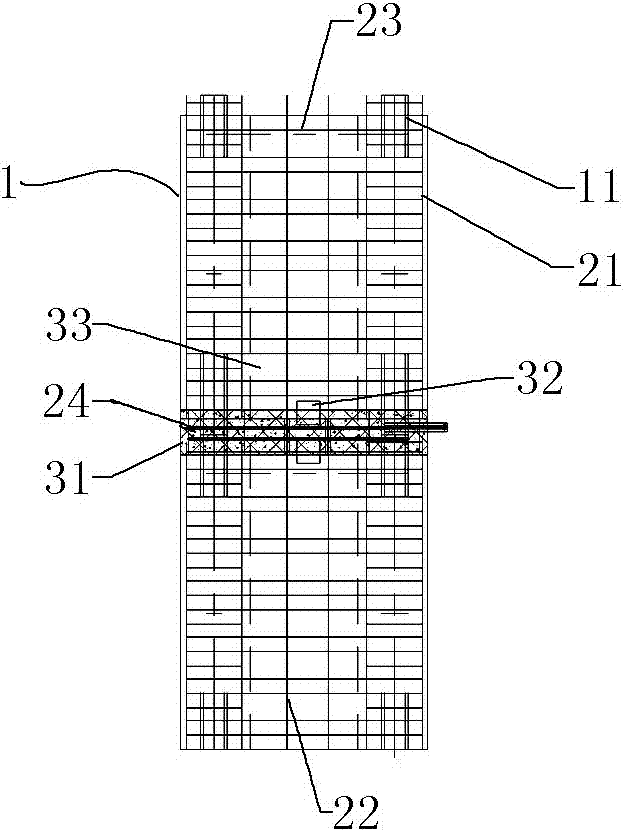

[0088] Such as Figure 1-Figure 3 As shown, the reinforced prefabricated reinforced concrete shear wall of the present invention is composed of prefabricated wall panels 1 connected up and down, and the cross section of the prefabricated wall panels 1 is in the shape of "one"; The reinforced vertical steel frame 11, steel bars and poured concrete wall body 33, the reinforced vertical steel frame 11 is discontinuously arranged, and is respectively arranged at the joints of the upper and lower ends of the prefabricated wall panel 1, and the reinforced vertical steel frame 11 is an I-shaped Steel; the reinforced vertical steel frame 11 is welded with studs and / or shear parts; the reinforcement includes edge reinforcement and non-edge reinforcement, the edge reinforcement includes edge longitudinal reinforcement 21, and the edge longitudinal reinforcement 21 is fixed by horizontal stirrups or tie bars, Set outside the reinforced vertical steel frame 11, the outer side of the reinf...

Embodiment 2

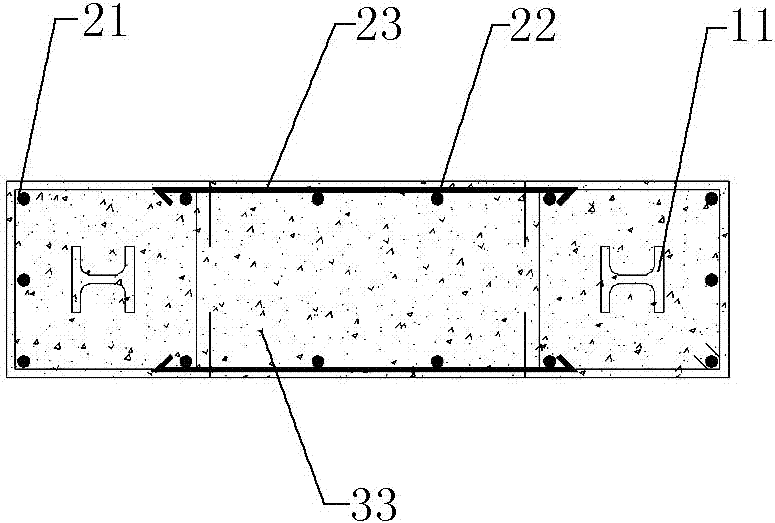

[0097] The reinforced prefabricated reinforced concrete shear wall of the present invention is the same as the embodiment 1, and is composed of prefabricated wall panels 1 connected up and down, wherein the cross section of the prefabricated wall panels 1 is in the shape of "one"; Figure 4 and Figure 5 As shown, the prefabricated wall panel 1 includes a reinforced vertical steel frame 11 arranged in the edge area of the prefabricated wall panel 1, steel bars, poured concrete wall body 33 and reinforcements arranged in the prefabricated wall panel 1, and the reinforced vertical steel frame 11 Discontinuously set, respectively set at the connection nodes of the upper and lower ends of the prefabricated wall panel 1, the reinforced vertical steel frame 11 is I-shaped steel; the steel bars include edge steel bars and non-edge steel bars, the edge steel bars include edge longitudinal bars 21, edge longitudinal bars 21 is fixed by horizontal stirrups or tie bars, set outside the...

Embodiment 3

[0099] The reinforced prefabricated reinforced concrete shear wall of the present invention is the same as Embodiment 1, and is composed of prefabricated wall panels 1 connected up and down, wherein the cross section of the prefabricated wall panels 1 is L-shaped; as Figure 6 and Figure 7 As shown, the prefabricated wall panel 1 includes reinforced vertical steel frames 11, steel bars, poured concrete wall body 33 arranged in the edge area of the prefabricated wall panel 1 and the corner area of the L-shaped prefabricated wall panel 1 and arranged in the prefabricated wall panel 1 Reinforcing parts, reinforced vertical steel bars 11 are arranged discontinuously, respectively arranged at the joints at the upper and lower ends of the prefabricated wall panel 1, and the reinforced vertical steel bars 11 are H-shaped steel; the reinforcing bars include edge steel bars and non-edge steel bars, and edge steel bars Including the edge longitudinal reinforcement 21, the edge long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com