Preparation method of surface molecularly imprinted polymers in water phase application

A surface molecular imprinting and polymer technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor practicability, large material contact angle, long processing time, etc., and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

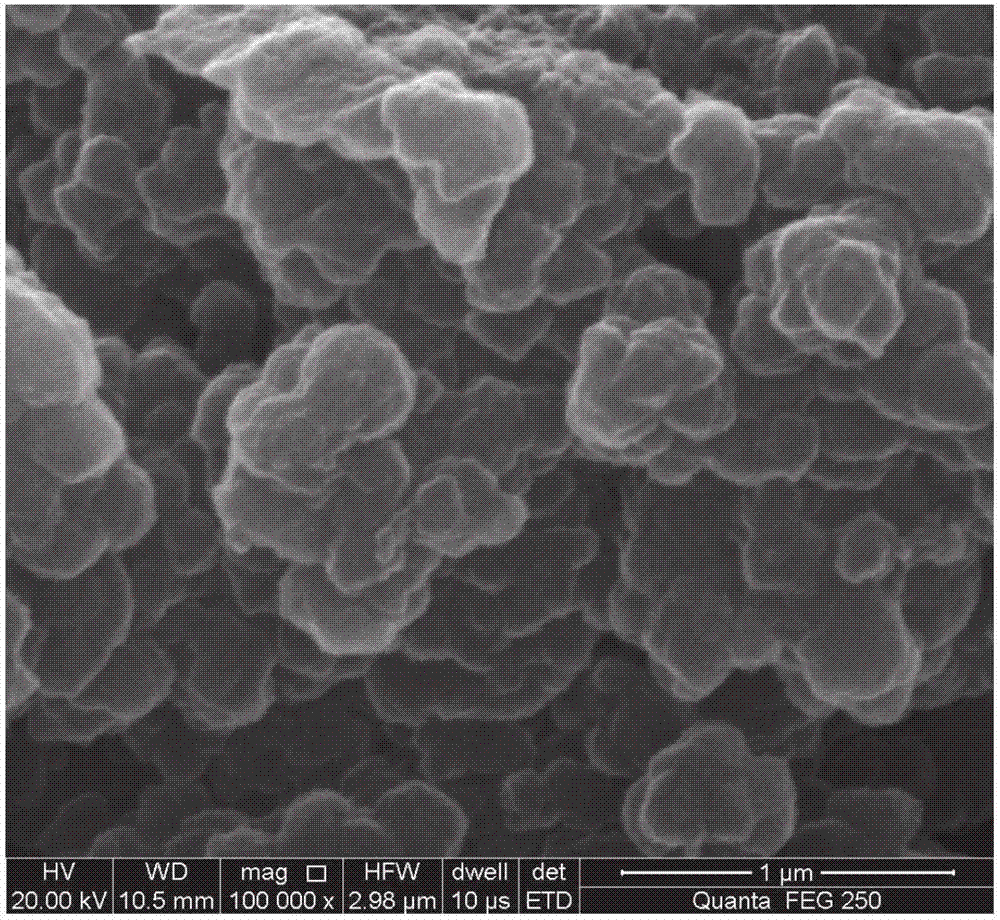

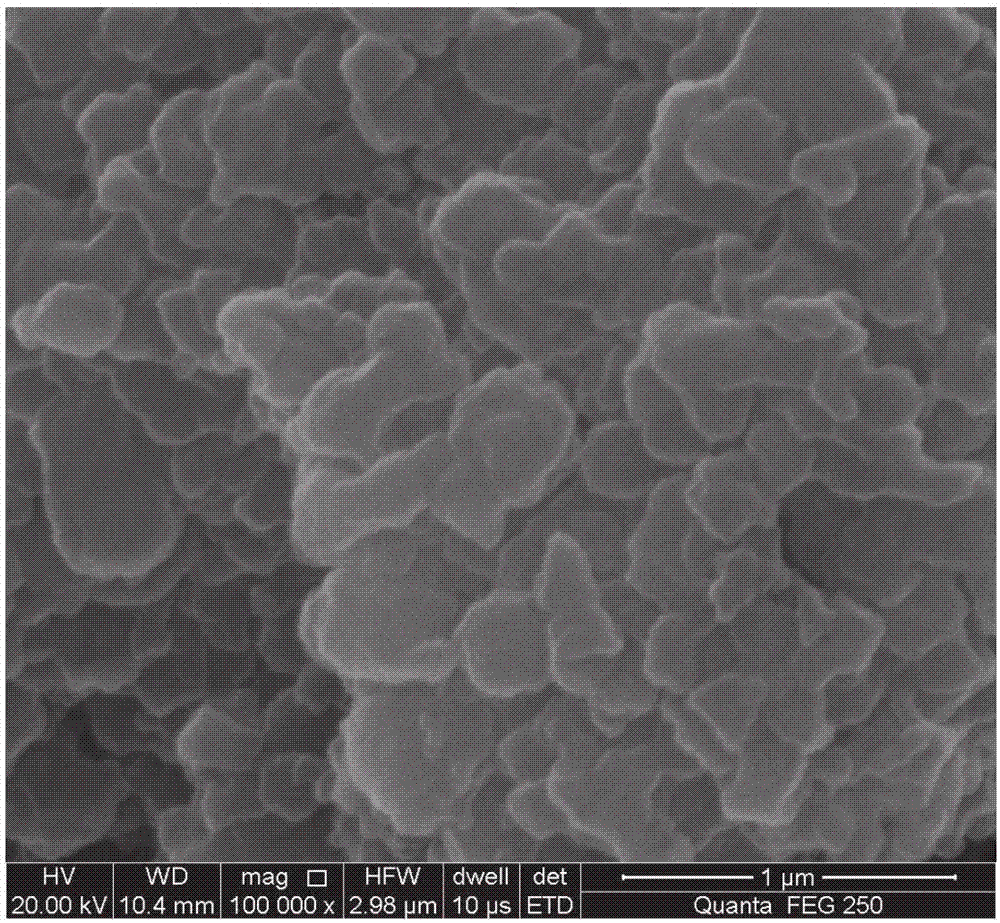

[0075] Example 1 Preparation of naringin surface molecularly imprinted polymer SMIPs

[0076] (1) Synthesis of metal-organic gel MOGs

[0077] Fe(NO 3 ) 3 9H 2 O and trimellitic acid (H 3 BTC) were dissolved in ethanol at a molar ratio of 3:2, and every mmol of Fe(NO 3 ) 3 9H 2 Add 7ml of ethanol to O, every mmol of H 3 Add 15ml of ethanol to BTC, and mix the two thoroughly under vigorous stirring to obtain gel-like MOGs.

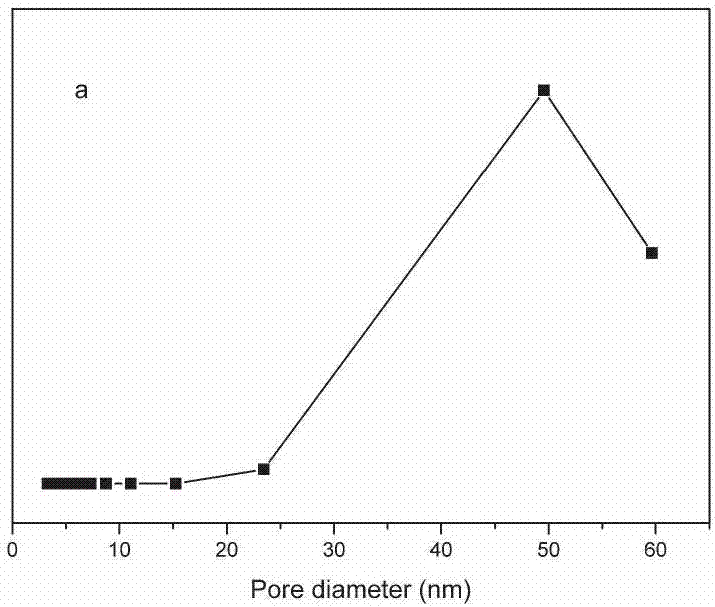

[0078] (2) Synthesis of macroporous carrier

[0079] Mix MOGs, glycidyl methacrylate (GMA), ethylene glycol dimethacrylate (EDMA) and azobisisobutyronitrile (AIBN), add GMA 0.4mmol, EDMA 0.27mmol, AIBN 0.8 per gram of MOGs mg. Under the protection of nitrogen, stir and react at 60°C for 24 hours, separate solid and liquid, wash repeatedly with 0.25mol / L sulfuric acid solution until no iron ions can be detected in the washing liquid, then wash with water and ethanol until the washing liquid has no UV absorption, and vacuum dry at 60°C , to obtain ...

Embodiment 2

[0086] Embodiment 2: Selective adsorption experiment

[0087] Take the aqueous solution of 20mg / ml naringin and the structural analog (pigenin and rutin) of naringin respectively as sample solution, under the same conditions, carry out adsorption with SMIPs and SNIPs prepared by embodiment 1 and blank control Experiments were carried out to measure the amount of adsorption and evaluate the recognition selectivity of SMIPs. Accurately weigh about 30mg of SMIPs and SNIPs and add them to two 10.00ml sample aqueous solutions (20mg / ml, pH 8.0), and shake at a constant temperature of 25°C for 10 minutes to carry out adsorption experiments. Solid-liquid separation, according to the change of sample concentration before and after adsorption, calculate Adsorption capacity.

[0088] The adsorption amounts of SMIPs and SNIPs for naringin were 6.49 μmol / g and 2.01 μmol / g, respectively, and the imprinting factor was 3.25; the adsorption amounts for apigenin were 0.041 μmol / g and 0.024 μmo...

Embodiment 3

[0089] Embodiment 3 adsorption kinetics experiment and desorption experiment

[0090] Take 10.00ml of naringin aqueous solution (20mg / ml) as sample solution, accurately weigh about 30mg of SMIPs (embodiment 1) to carry out adsorption experiment, take samples and analyze at different times, calculate the adsorption capacity, and obtain Figure 6 The adsorption kinetic curve shown in the figure evaluates the adsorption speed of SMIPs for template molecules. From Figure 6 It can be seen that SMIPs reached the adsorption equilibrium for naringin in about 3 minutes, indicating that the SMIPs prepared by the present invention have a very fast adsorption speed for template molecules and have excellent adsorption kinetic properties.

[0091] Take the above SMIPs whose adsorption has reached equilibrium for solid-liquid separation, add 10.00ml of acetic acid solution (pH3.0) to the solid and shake at a constant temperature of 25°C for 10 minutes for desorption experiment, separate so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com