Electronic dynamic control and chemical auxiliary corrosion-based machining method for oval microlens

A technology of electronic dynamic regulation and assisted etching, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of complex processing technology, high equipment requirements, complicated operation, etc., to simplify the construction process, high-quality preparation, The effect of efficient machining methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

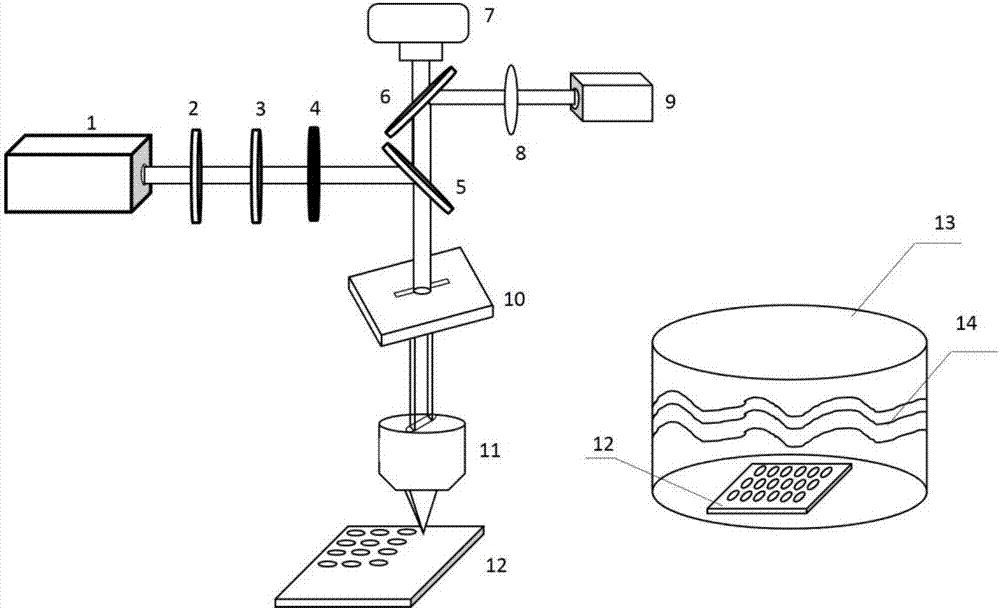

[0022] like figure 1 As shown, taking the surface-polished fused silica as an example, an elliptical microlens processing method based on electronic dynamic control and chemically assisted etching is based on the following devices: femtosecond laser system 1, half-wave plate 2, polarizer 3, mechanical Switch 4, dichroic mirror 5, beam splitter 6, illumination white light source 7, focusing lens 8, imaging CCD 9, slit 10, plano-convex lens 11, sample 12, solution container 13 and etching solution 14;

[0023] The processing optical path is the femtosecond laser generated by the femtosecond laser system 1. After passing through the half-wave plate 2, the polarizer 3 and the mechanical switch 4, it is reflected by the dichroic mirror 5, and then focused to the fused silica after passing through the slit 10 and the plano-convex lens 11. 12 surfaces; the illumination white light source 7 irradiates the surface of the fused silica material 12 after passing through the beam splitter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com