Temperature difference power generation device of bus air exhaust pipe

A thermoelectric power generation and bus technology, applied in the direction of generators/motors, electrical components, etc., can solve the problem of not passing the cooling water circulation, and achieve the effect of improving heat utilization, high safety, and reducing bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

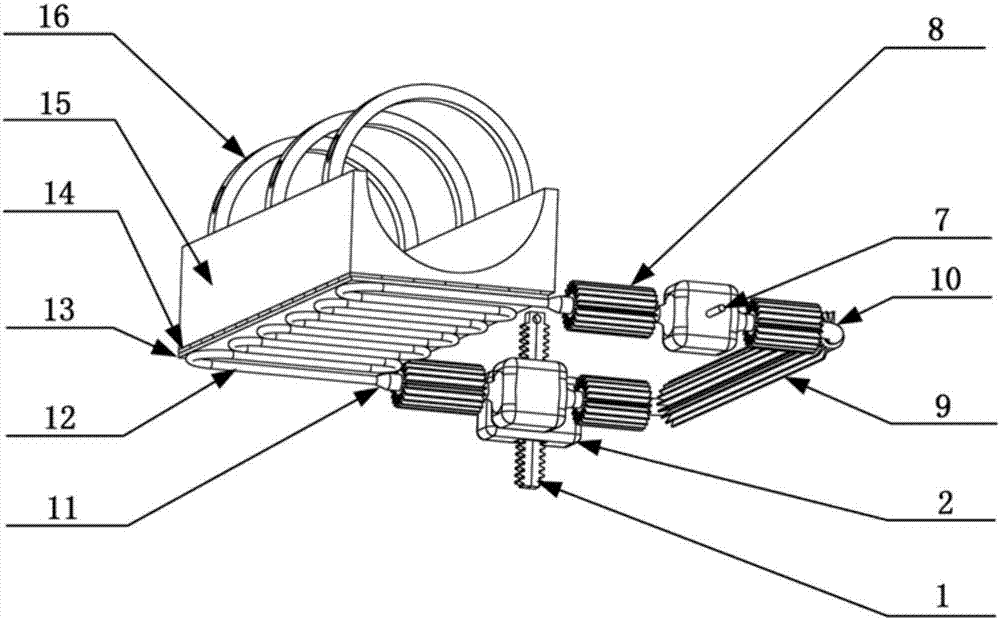

[0041] figure 1 Show the bus exhaust pipe temperature difference power generation device, the cooling water inlet and outlet ends of the heat-absorbing copper pipe 12 or the cooling water inlet and outlet ends of the heat-absorbing copper plate with a liquid circulation cavity are connected with the U-shaped cooling pipe respectively The two ends of 10 are connected to form a cooling water circuit; the heat-absorbing copper tube 12 is fixed on the bottom surface of the metal plate 13; Between the planes, or, the thermoelectric generating sheet 14 is crimped between the bottom plane of the heat-absorbing copper plate and the copper arc-shaped groove 15, and the above-mentioned inner curved surface of the arc-shaped groove 15 used as a fixed bus exhaust pipe is in contact with the bus. The shape of the exhaust pipe matches; the first w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com