Coal mining machine material blocking mechanism suitable for large-pitch mining angle and wide mining high-range working surfaces

A material retaining mechanism and shearer technology, applied in cutting machinery, earth-moving drilling and other directions, can solve problems such as safety hazards, reduce the possibility of overturning, solve personal safety problems, and improve safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

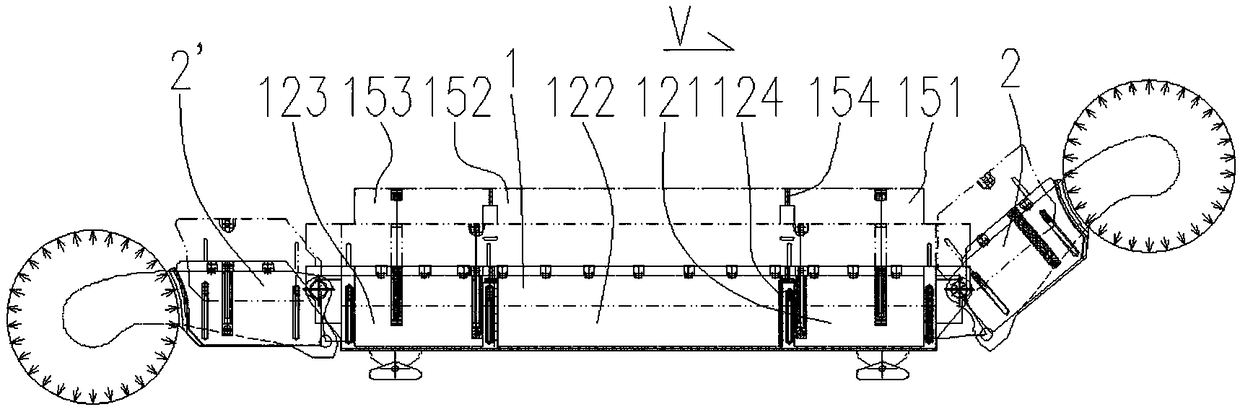

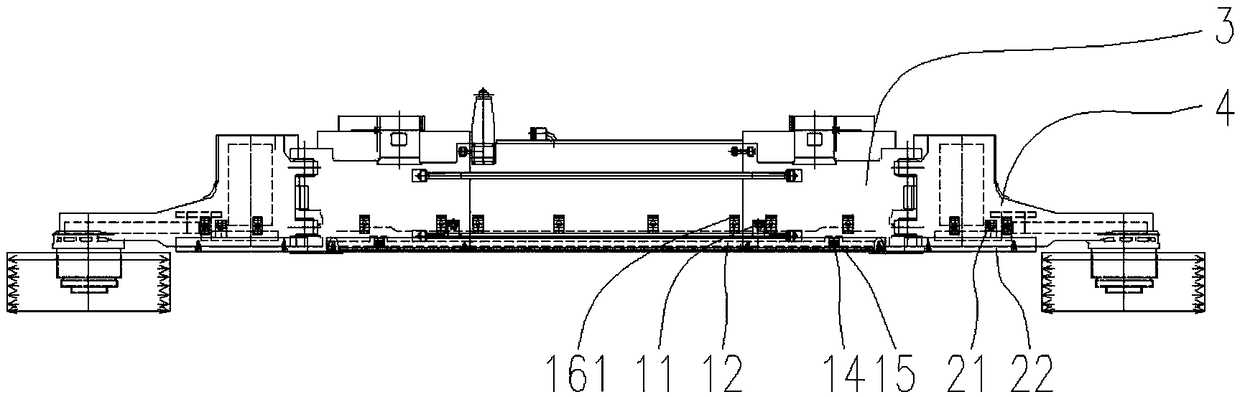

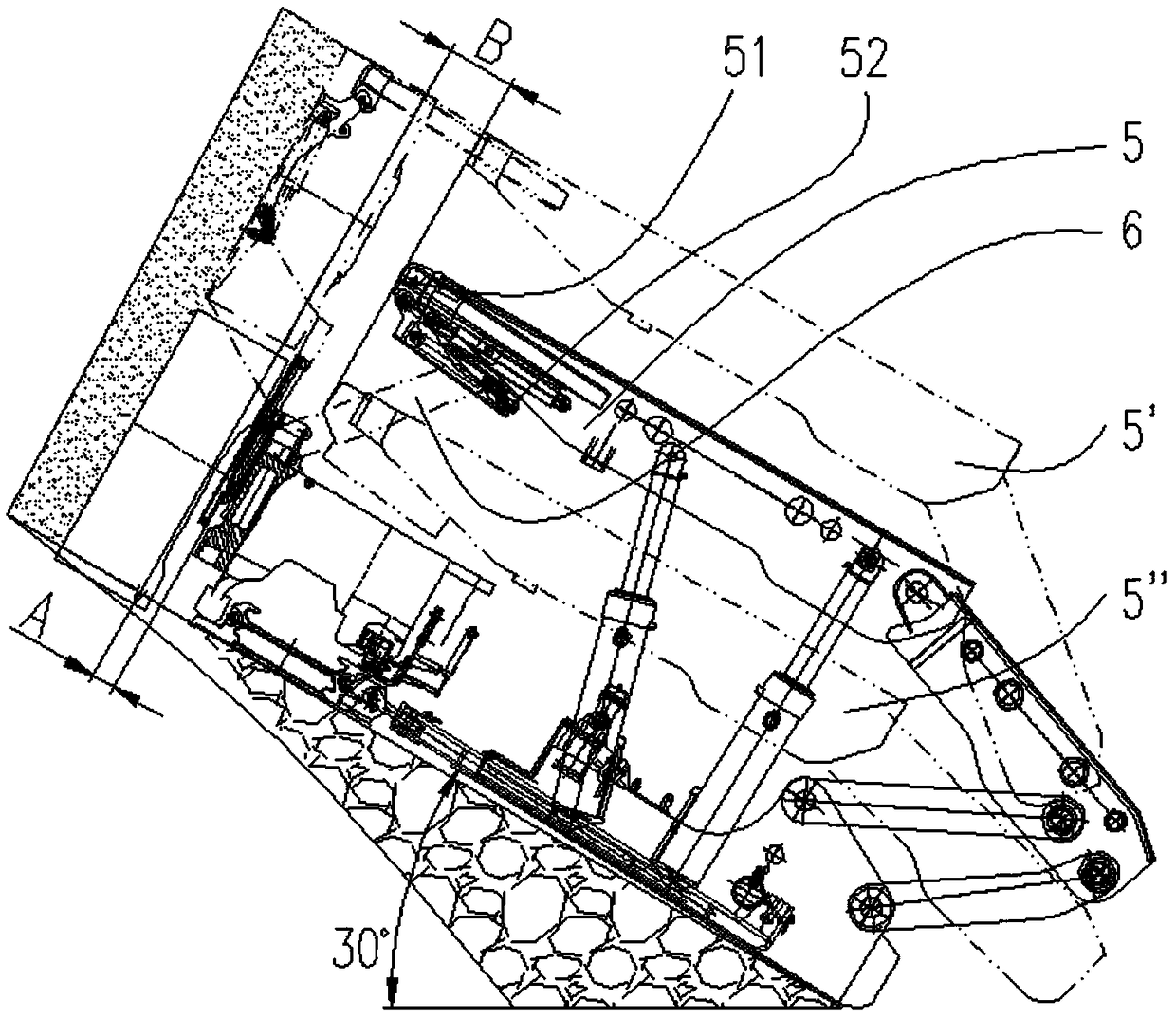

[0044] The invention discloses a shearer stopper mechanism (referred to as stopper mechanism) adapted to a working face with a large elevation mining angle and a wide mining height range, as shown in Fig. Body 3 front side and rocker arm housing 4 front side of the fuselage stop device 1 and rocker arm stop device 2. The fuselage stopper includes a fuselage primary stopper 12, a fuselage secondary stopper 15, a first telescopic mechanism 11 and a second telescopic mechanism 14, and the fuselage primary stopper is in the first Driven by the telescopic mechanism 11, it moves up and down relative to the fuselage in a plane parallel to the front side 32 of the fuselage shell. The plane of the front side 32 of the body moves up and down relative to the primary baffle plate of the fuselage. The rocker arm material blocking device includes a rocker arm material blocking plate 22 and a third telescopic mechanism 21, and the rocker arm material blocking plate is driven by the third te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com