Argillaceous soft rock roadway partition multi-granularity grouting reinforcement method

A technology of grouting reinforcement and multi-grain size, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of micro-pores and micro-cracks, unsatisfactory reinforcement effects, insufficient cohesive force of silica sol, etc. Achieve the effects of reducing permeability, weakening impact, increasing deformation resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A coal mine has a rectangular cross-section roadway, width × height = 5.0 × 3.6m, the roof is siltstone, rich in fissure water; the side and floor are mudstone with micro-porous fractures, which will be cemented. In order to control the large flow deformation of the roadway, the cement slurry and silica sol area grouting reinforcement method is used for grouting.

[0040] After the roadway is excavated, anchor in time, spray concrete and silica sol, the thickness of concrete spraying is 100mm, re-spray silica sol, silica sol is the existing material, composed of A and B materials, A material is silica colloid, B material is a catalyst Sodium chloride solution, the parameters used are A material: B material = 4:1, and the thickness is 2mm.

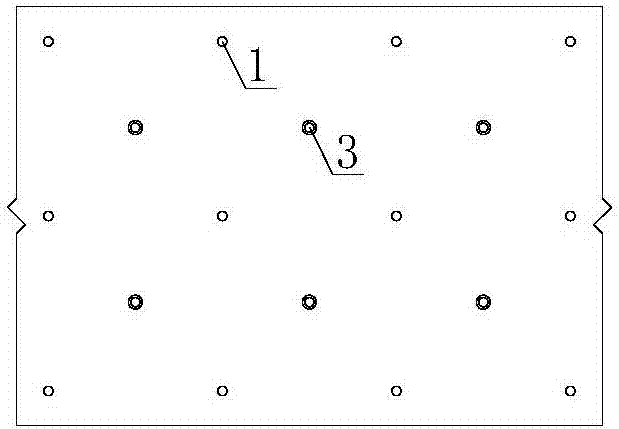

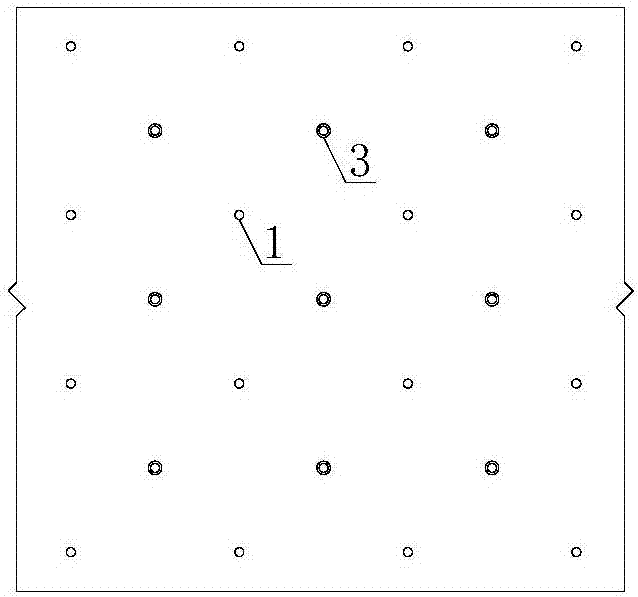

[0041] After 15 days of roadway excavation, construct shallow grouting holes 1 in the side and bottom plate, the hole depth is 2.2m, and the row spacing is 1.5m×1.5m. The angle between shallow grouting holes 1 at two corners and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com