Water-repellency packaging paper based on nanometer plant fibers and preparing method thereof

A technology of plant fiber and nano-cellulose, which is applied in packaging paper, wrapping paper, using microorganism/enzymatic cellulose treatment, etc., can solve the problems of water repellency and rareness of plant fiber paper, achieve a small size range, and a preparation method Simple, Manipulable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

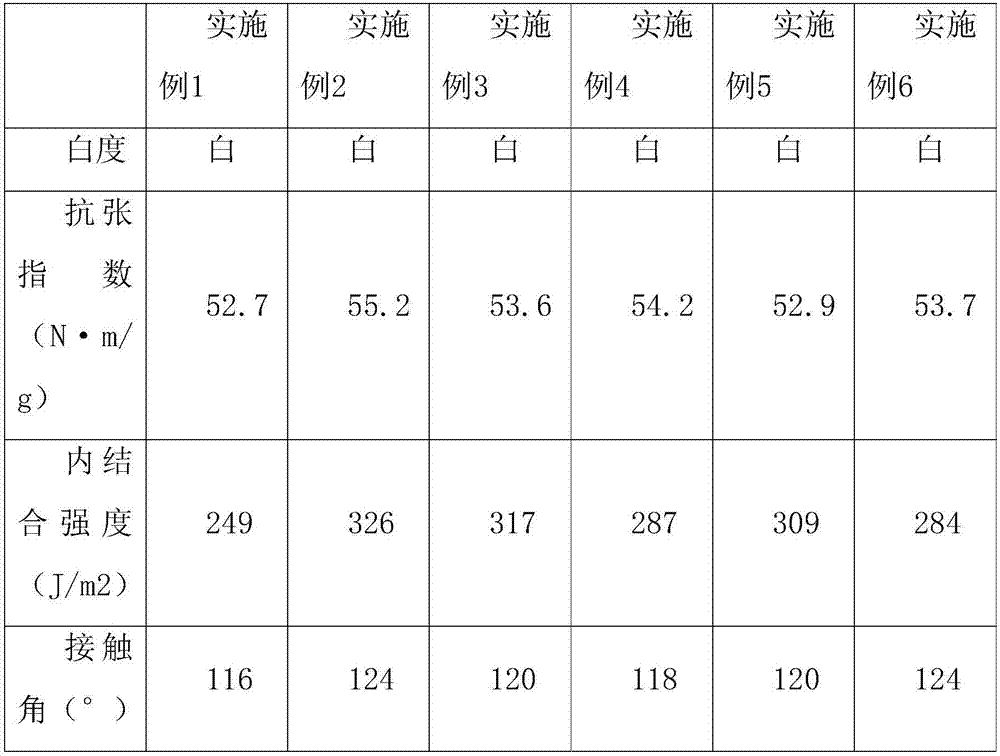

Examples

Embodiment 1

[0026] (1) The rice straw was dried in the sun, beaten thoroughly, immersed in 20g / L sodium hydroxide solution, heated and boiled for activation for 20 minutes, adjusted to neutral pH, and taken out to obtain pretreated rice straw.

[0027] (2) Place the pretreated rice straw in a biological enzyme solution containing 1% cellulase and 2% xylanase, stir it ultrasonically for 10 min at a power of 100W, and add acetic acid and molybdenum at a volume ratio of 3:1 Acid and inorganic acid mixed solution, continue to ultrasonically stir for 10min under 100W power, take it out, filter it with an ultrafiltration membrane with a pore size of 100nm, wash with water, and obtain nano-plant fibers, according to the material ratio of nano-plant fibers and hydrogen peroxide solution is 0.1g : 3ml, add dropwise hydrogen peroxide solution, and bleach at 40°C for 30min to obtain a solution containing nano-plant fibers.

[0028] (3) Add fillers, cationic starch, bentonite and sticky chemicals to ...

Embodiment 2

[0030] (1) Dry the rice straw, beat it fully, dip it in 30g / L sodium hydroxide solution, heat and boil to activate for 30min, adjust the pH value to neutral, take it out, and obtain the pretreated rice straw.

[0031] (2) Place the pretreated rice straw in a bio-enzyme solution containing 2% cellulase and 3% xylanase, stir it ultrasonically for 20min at a power of 150W, and add dropwise acetic acid and molybdenum at a volume ratio of 4:1 Acid and inorganic acid mixed solution, continue to ultrasonically stir for 20min under 150W power, take out, filter with an ultrafiltration membrane with a pore size of 100nm, and wash with water to obtain nano-plant fibers, according to the material ratio of nano-plant fibers and hydrogen peroxide solution is 0.1g : 5ml, hydrogen peroxide solution was added dropwise, and bleached at 60°C for 30min to obtain a solution containing nano-plant fibers.

[0032] (3) Add fillers, cationic starch, bentonite and sticky chemicals to the solution conta...

Embodiment 3

[0034] (1) The rice straw was dried in the sun, beaten thoroughly, immersed in 25g / L sodium hydroxide solution, heated and boiled for activation for 25 minutes, adjusted to neutral pH, and taken out to obtain pretreated rice straw.

[0035] (2) Place the pretreated rice straw in a bio-enzyme solution containing 1.5% cellulase and 2.5% xylanase, ultrasonically stir for 15 minutes at a power of 110W, and add dropwise acetic acid and molybdenum at a volume ratio of 3.5:1 Acid and inorganic acid mixed solution, continue to ultrasonically stir for 15min under 130W power, take out, filter with an ultrafiltration membrane with a pore size of 100nm, and wash with water to obtain nano-plant fibers, according to the material ratio of nano-plant fibers and hydrogen peroxide solution is 0.1g : 4ml, hydrogen peroxide solution was added dropwise, and bleached at 50°C for 30min to obtain a solution containing nano-plant fibers.

[0036] (3) Add fillers, cationic starch, bentonite and sticky ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com