Industrial antibacterial liquid and preparation method and special preparation device thereof

A technology for preparing device and antibacterial liquid, which is applied in the field of industrial antibacterial liquid and its preparation and special preparation device, which can solve the problems of fast decay of antibacterial effect, short antibacterial time limit, poor dispersion performance, etc., and achieve efficient dispersion process and excellent antibacterial Effect, performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

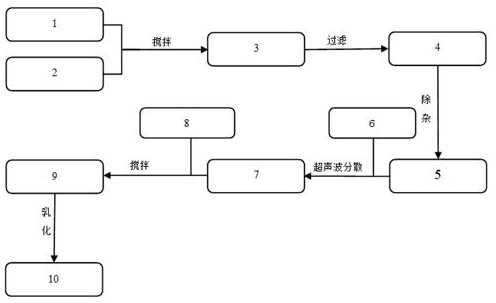

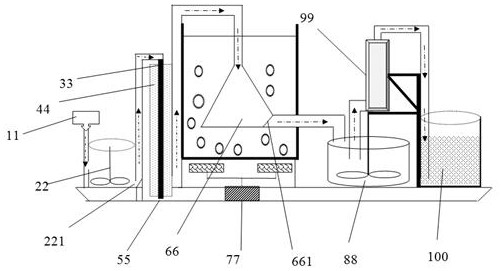

Method used

Image

Examples

Embodiment 1

[0036] An industrial antibacterial solution, including: nano-scale zinc oxide ZnO powder, 4,5-dichloro-2-n-octyl-3-isothiazolinone DCOIT, amino resin and methyl isobutyl ketone, each The parts by weight of the ingredients are: 0.1 part of zinc oxide ZnO powder, 5 parts of 4,5-dichloro-2-n-octyl-3-isothiazolinone DCOIT, 0.5 part of polyurethane acrylate, 10 parts of methyl isobutyl ketone share.

Embodiment 2

[0038] An industrial antibacterial solution, comprising: nano-scale zinc oxide ZnO powder, quaternary phosphonium salt, amino resin and ethyl acetate, the parts by weight of each component are: 8 parts of zinc oxide ZnO powder, 18 parts of quaternary phosphonium salt 10 parts, 10 parts of polyurethane acrylate, 40 parts of ethyl acetate.

Embodiment 3

[0040] An industrial antibacterial solution, comprising: nano-scale zinc oxide ZnO powder, quaternary ammonium salt, amino resin and methyl ethyl ketone, the parts by weight of each component are: 13 parts of zinc oxide ZnO powder, 15 parts of quaternary ammonium salt , 18 parts of polyurethane acrylate, 60 parts of butanone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com