Processing method of down-proof shell fabric of super-flexible noiseless down quilt

A processing method and noise-free technology, applied in dyeing, fabric surface trimming, improved handle fibers, etc., can solve the problems of low down-proof level, difficulty in both air permeability and hand feel, etc., to enhance softness and ensure use Comfort and quality of use, the effect of reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Processing of blended yarn: blending poly(trimethylene terephthalate) fiber and modal fiber at a mass ratio of 5:1, and then processing through cleaning, carding, drawing, roving and spun yarn into blended yarn;

[0024] (2) Dyeing of blended yarn: Exhaust dye the blended yarn, and at the same time mix softening additives into the dyeing solution, so that the mass ratio of blended yarn and softening additive reaches 1:0.05, and then fix at 50-60°C after dyeing. Color for 20 minutes, and processed by water washing, dehydration and drying;

[0025] (3) fabric weaving: warping, sizing, and reeding the dyed blended yarn on the loom to weave plain weave fabric;

[0026] (4) Pre-treatment of fabric calendering: add calendering aid and boiling water to make a solution with a mass concentration of 25g / l, cool naturally to 50-60°C, then dip the fabric obtained from weaving into the solution, and dry it at 50 Keep warm at -60°C for 30 minutes, then take out the fabric, and ...

Embodiment 2

[0031] (1) Processing of blended yarn: blending poly(trimethylene terephthalate) fiber and modal fiber at a mass ratio of 7:2, and then processing through cleaning, carding, drawing, roving and spun yarn into blended yarn;

[0032] (2) Dyeing of blended yarn: Exhaust dye the blended yarn, and at the same time mix softening additives into the dyeing solution, so that the mass ratio of blended yarn and softening additive reaches 1:0.05, and then fix at 50-60°C after dyeing. Color for 30 minutes, and processed by water washing, dehydration and drying;

[0033] (3) fabric weaving: warping, sizing, and reeding the dyed blended yarn on the loom to weave plain weave fabric;

[0034] (4) Pre-treatment of fabric calendering: add calendering aid and boiling water to make a solution with a mass concentration of 30g / l, cool naturally to 50-60°C, then dip the fabric obtained from weaving into the solution, and dry it at 50 Keep warm at -60°C for 30 minutes, then take out the fabric, and ...

Embodiment 3

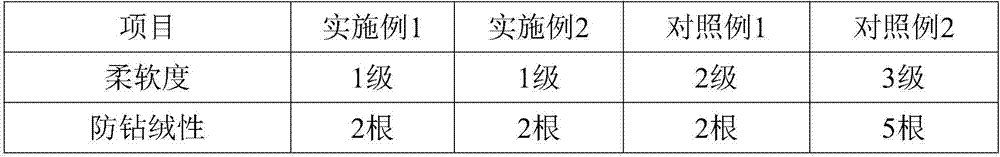

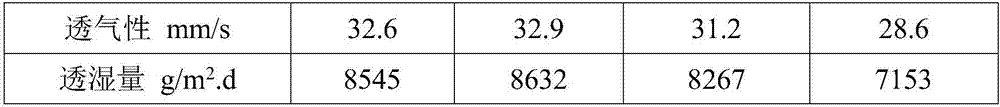

[0052] Utilize the methods described in Example 1, Example 2, Comparative Example 1, and Comparative Example 2 to process and prepare the duvet fabric respectively, and measure its performance. The results are shown in Table 1.

[0053] Table 1 The service performance of the processed duvet fabric made by the present invention

[0054]

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com