Method for depositing amorphous silicon membrane through PECVD (plasma enhanced chemical vapor deposition)

An amorphous silicon thin film and deposition technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve problems such as the impact of product yield, and achieve the effect of reducing the generation of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Because the method of the embodiment of the present invention is formed on the basis of breaking through the conventional thinking of those skilled in the art, the proposal of the technical problem of the present invention itself has creativity, so before introducing the method of the embodiment of the present invention in detail, first introduce the existing method:

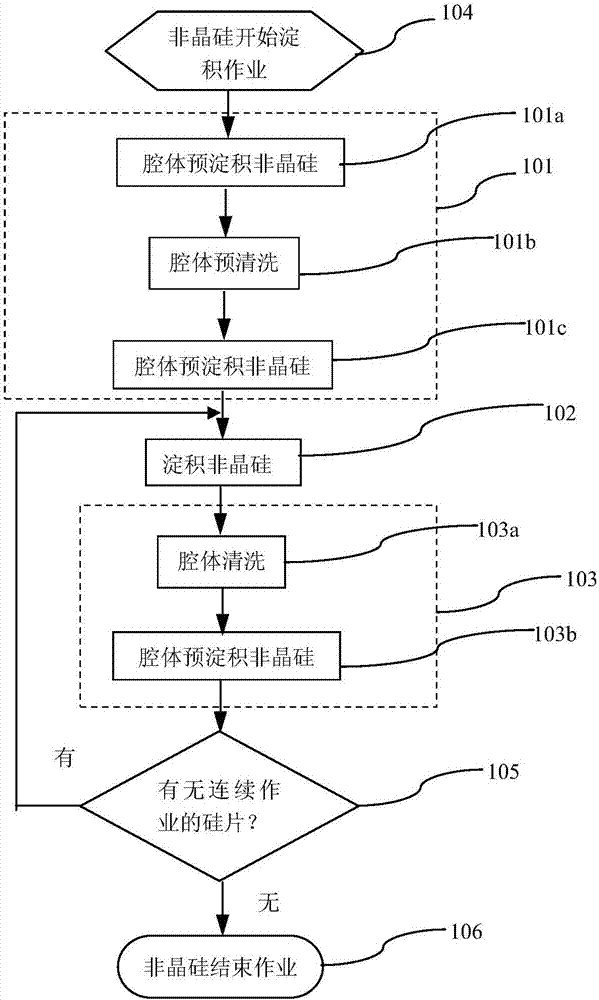

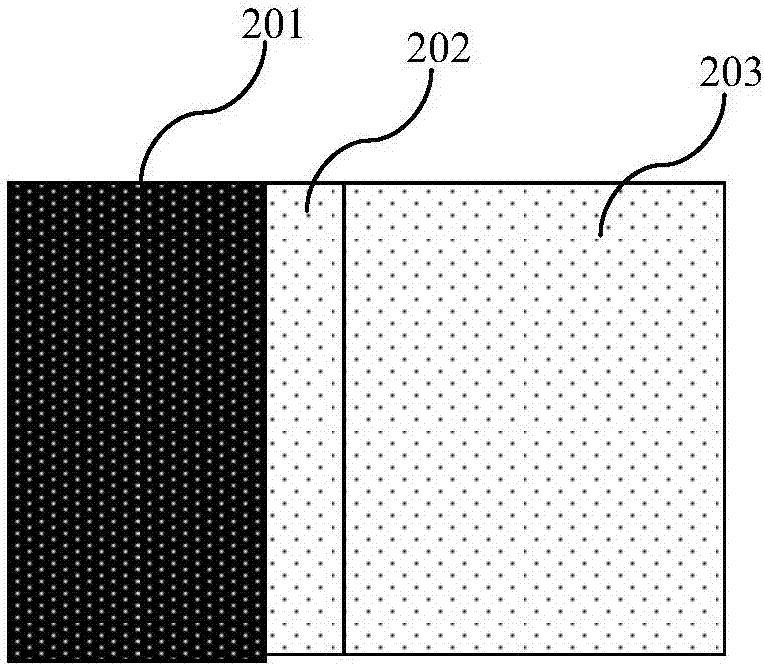

[0039] Such as figure 1 Shown is the flow chart of the method for depositing amorphous silicon thin film by existing PECVD; figure 2 Shown is the film structure diagram formed on the inner wall of the process chamber 201 in the existing method for depositing an amorphous silicon thin film by PECVD; the existing method for depositing an amorphous silicon thin film by PECVD includes steps:

[0040] The first step after starting the deposition of amorphous silicon, that is, step 1, is to perform an inter-batch pretreatment step, and the deposition of amorphous silicon starts at figure 1 Indicated by mark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com