Multilayer cooling blast-furnace cooling stave and processing technology thereof

A processing technology and cooling wall technology, applied in cooling devices, metal processing equipment, manufacturing tools, etc., can solve problems such as poor cooling effect and melting of cooling water pipes, to ensure cooling effect, improve cooling uniformity, and increase distribution. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

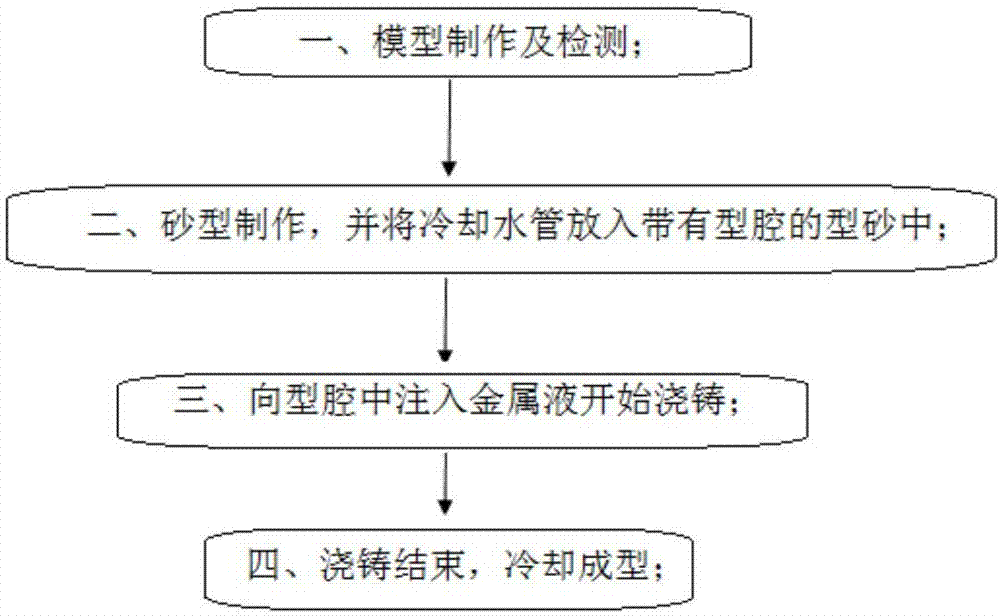

[0042] A kind of processing technique of the blast furnace stave of multilayer cooling of the present embodiment, comprises the following steps:

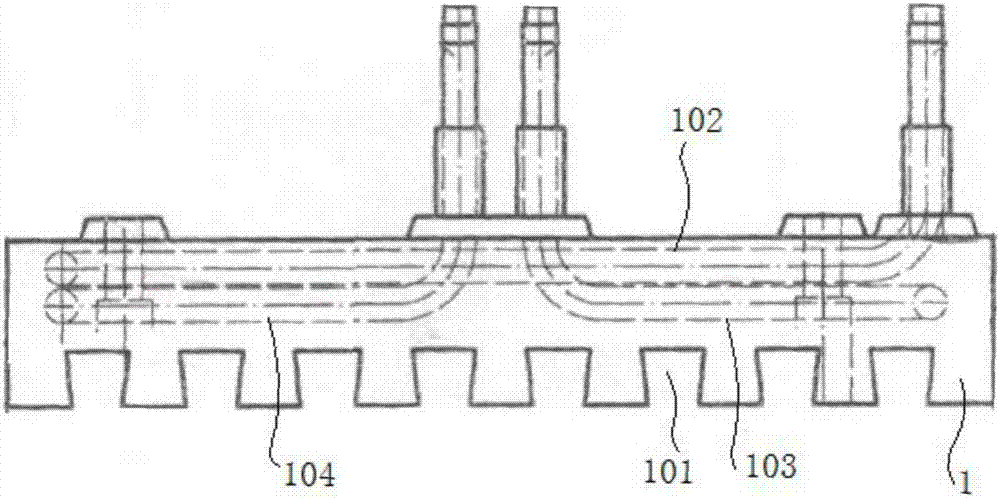

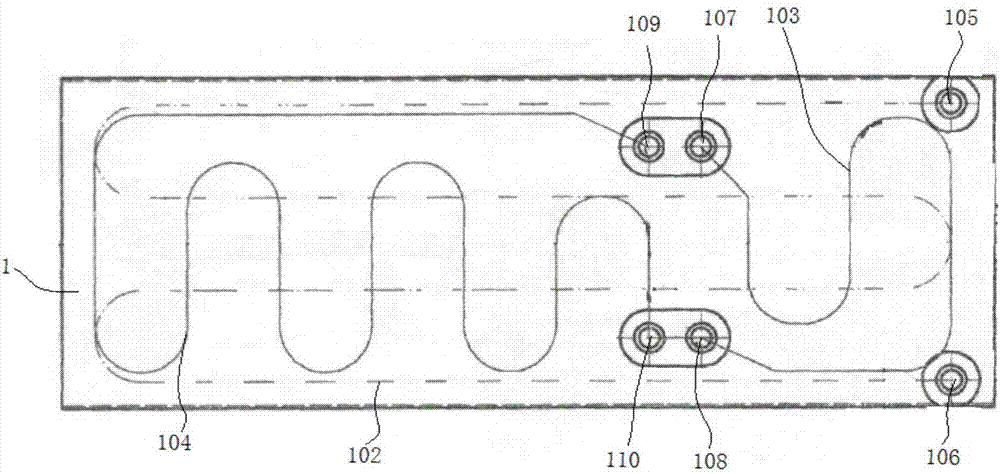

[0043] Step 1. Manufacturing and testing of stave wooden molds: making stave wooden molds according to the structural shape of stave body 1, and testing the shape and dimension accuracy of the stave wooden molds, and selecting qualified products to enter the next process; 1 is structured as figure 2 and image 3 shown, press figure 2 In terms of the middle position, the bottom surface of the stave body 1 bottom is the inner working surface, and the inner side surface of the stave body 1 is provided with a brick-embedded groove 101 for inlaying refractory bricks; The overall length and width of the inner side of the brick-embedded groove 101 is 1.6% larger than that of the stave body 1, and the overall length and width of the outer side of the wooden formwork of the stave away from the brick-embedded groove 101 is 2.1% larger tha...

Embodiment 2

[0060] The processing technology of the blast furnace stave of a kind of multi-layer cooling of the present embodiment is basically the same as embodiment 1, and difference is:

[0061] In step 1 of the present embodiment, the stave wood formwork is provided with the length and width of the inner side of the brick-embedded groove 101. The overall size is 1.8% larger than the stave body 1, and the length and width of the outer side of the stave wood formwork away from the brick-embedded groove 101 are overall. The dimensions are all 2.2% larger than the stave body 1;

[0062] In this embodiment, the thickness H1 of the cold iron 111 is 2 / 3 of the wall thickness H2 of the cooling water pipe. The length of a single piece of cuboid-shaped cold iron 111 is 5 cm and the width is 5 cm. The cold iron 111 at the bottom of a certain straight section of the cooling water pipe The total length L1 of the cooling water pipe is 1 / 35 of the length L2 of the straight section of the cooling wat...

Embodiment 3

[0065] The processing technology of the blast furnace stave of a kind of multi-layer cooling of the present embodiment is basically the same as embodiment 1, and difference is:

[0066] In step 1 of the present embodiment, the length and width of the inner side of the stave wood formwork provided with the brick-embedded groove 101 are all 1.7% larger than the stave body 1, and the length and width of the outer side of the stave wood formwork away from the brick-embedded groove 101 are overall The dimensions are all 2.2% larger than the stave body 1;

[0067] In the present embodiment, the monolithic length of the cuboid flaky cold iron 111 is 5.5 cm, and the width is 4.5 cm. The total length L1 of the cold iron 111 at the bottom of a certain section of the straight section of the cooling water pipe is 1 of the length L2 of this section of the straight section of the cooling water pipe. / 30, the cold iron 111 at the lower part of the straight section of the cooling water pipe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com