Deproteinization and decoloration method for mango processing by-product polysaccharide

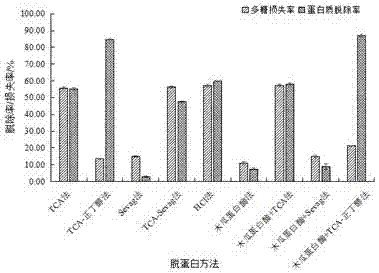

A deproteinization and by-product technology, applied in the field of mango processing by-product polysaccharide deproteinization and decolorization, can solve the problems of optimization, no mango polysaccharide deproteinization and decolorization process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

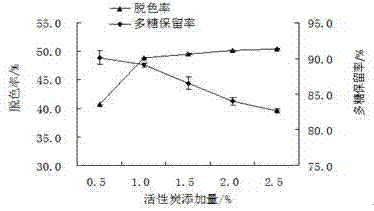

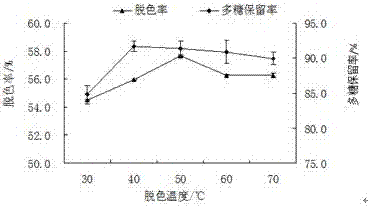

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 adopts the following steps to realize the present invention:

[0066] (1) Pretreatment of by-products of mango processing: select undamaged and disease-free mangoes, take the pomace, wash, slice, inactivate in a boiling water bath for 2 min, mix mango pomace with Mixed with distilled water, homogenized in a masher to obtain a homogenized mango peel residue, refrigerated at 4°C for later use;

[0067](2) Extraction of mango crude polysaccharides: Take 30g of mango peel residue homogenate treated in step (1), add 90mL of distilled water, rehydrate for 30min, adjust pH to 5.0, add cellulase with 1.0% of mango peel residue mass, and use ultrasonic Use the power of 240W in the washing machine, extract at 50°C for 60min, heat up to 90°C to inactivate the enzyme for 30min; the obtained extract is centrifuged at 6000r / min for 10min, the supernatant is collected, and the residue is repeatedly extracted once; the extract is separated from the supernatant , concentra...

Embodiment 2

[0070] Embodiment 2 adopts the following steps to realize the present invention:

[0071] (1) Pretreatment of by-products of mango processing: select undamaged and disease-free mangoes, take the skin dregs, wash, slice, inactivate in a boiling water bath for 2 min, mix the mango skin dregs with the Mixed with distilled water, homogenized in a masher to obtain a homogenized mango peel residue, refrigerated at 4°C for later use;

[0072] (2) Extraction of mango crude polysaccharides: take 30 g of mango peel residue homogenate treated in step (1), add 120 mL of distilled water, rehydrate for 30 minutes, adjust pH to 5.0, add cellulase with 0.8% of mango peel residue mass, and use ultrasonic In the washing machine, extract at 50°C for 80min with a power of 300W, and then heat up to 90°C to inactivate the enzyme for 30min. The obtained extract was centrifuged at 5000r / min for 10min, the supernatant was collected, and the residue was repeatedly extracted once; the supernatant was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com