Disc sand screening machine with cleaning device

A technology of cleaning device and sand screening machine, which is applied in the direction of filter screen, solid separation, grille, etc., which can solve the problems of difficult use and movement, high labor intensity, and low work efficiency, so as to ensure the service life and good cleaning effect , The effect of fast sand screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

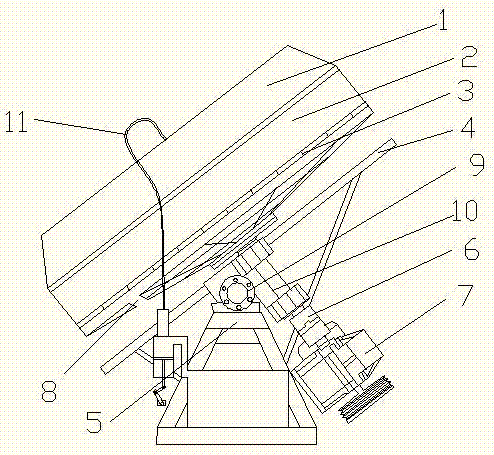

[0015] A disc sand screening machine with a cleaning device, which is composed of Figure 1-Figure 3 Shown, comprise frame 5, frame 5 is provided with rotating beam 9, is provided with main shaft 10 on rotating beam 9, and the upper end of main shaft 10 is connected with disc 2, and main shaft 10 is connected with disc 2 through collecting tray 4, The disc 2 is provided with a sand screen 3; the disc 2 is provided with an anti-overflow ring 1 and a sand discharge port 8, a collection plate 4 is provided below the sand discharge port 8, and a reduction motor 7 is provided at the lower end of the main shaft 10; Described frame 5 is also provided with cleaning device; Described cleaning device comprises water tank 23, and water tank 23 is connected with pressurized cavity 24 through pipeline 22, and pipeline 22 and water tank 23 joints are provided with check valve 26, add Pressing cavity 24 is provided with briquetting block 13, and briquetting block 13 is connected with first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com