Preservative for canned yellow peaches and preparation method of preservative

A technology of canned yellow peaches and preservatives, applied in food ingredients as antioxidants, food preservation, food ingredients as anti-microbial preservation, etc., can solve the problems of no preservatives, limited use range, etc., to extend the shelf life, improve The effect of anti-corrosion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

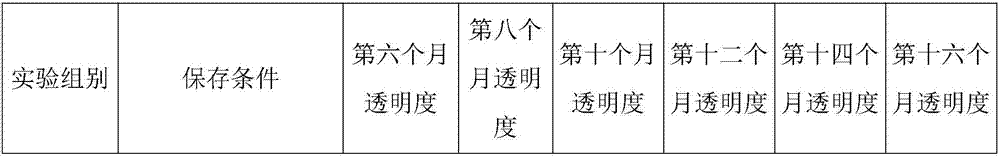

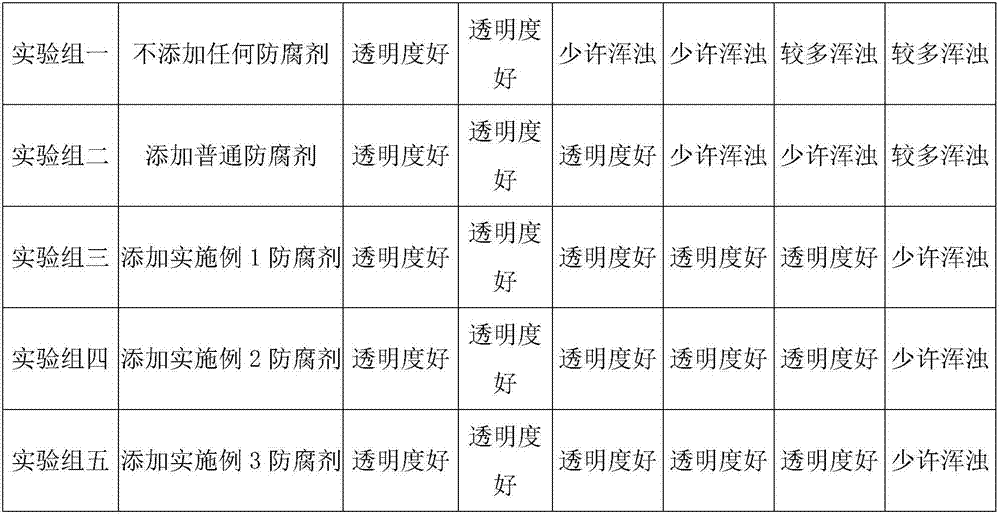

Image

Examples

Embodiment 1

[0030] A kind of canned yellow peach preservative, by weight percentage, its formula is composed as follows:

[0031] Diacetate 2%, yellow peach leaf extract 1%, lysozyme 3%, benzoic acid 0.5%, cinnamon oil 1.2%, citric acid 0.2%, gibberellin 0.8%, nisin 0.7%, and the rest is water.

[0032] Described diacetate is sodium diacetate.

[0033] The preparation method of above-mentioned preservative comprises the following steps:

[0034] (1) prepare yellow peach leaf extract

[0035] The yellow peach leaves are dried and crushed, passed through a mesh sieve, put into an extraction tank, add petroleum ether extraction solvent 2-3 times the weight of the yellow peach leaves, pressurize to 150-200Mpa and maintain the pressure for 10-15min, then release the pressure and filter, the filtrate is placed in The first refrigeration is carried out in the refrigerator, the temperature of the first refrigeration is 0-5°C, and the refrigeration time is 1-2 hours. After the first refrigeratio...

Embodiment 2

[0041] A kind of canned yellow peach preservative, by weight percentage, its formula is composed as follows:

[0042] Diacetate 3.5%, yellow peach leaf extract 2%, lysozyme 4%, benzoic acid 0.7%, cinnamon oil 1.3%, citric acid 0.4%, gibberellin 1.0%, nisin 0.8%, and the rest is water.

[0043] Described diacetate is sodium diacetate.

[0044] The preparation method of above-mentioned preservative comprises the following steps:

[0045] (1) prepare yellow peach leaf extract

[0046] The yellow peach leaves are dried and crushed, passed through a mesh sieve, put into an extraction tank, add petroleum ether extraction solvent 2-3 times the weight of the yellow peach leaves, pressurize to 150-200Mpa and maintain the pressure for 10-15min, then release the pressure and filter, the filtrate is placed in The first refrigeration is carried out in the refrigerator, the temperature of the first refrigeration is 0-5°C, and the refrigeration time is 1-2 hours. After the first refrigerat...

Embodiment 3

[0052] A kind of canned yellow peach preservative, by weight percentage, its formula is composed as follows:

[0053] Diacetate 5%, yellow peach leaf extract 3%, lysozyme 5%, benzoic acid 1.0%, cinnamon oil 1.5%, citric acid 0.6%, gibberellin 1.2%, nisin 1.0%, and the rest is water.

[0054] Described diacetate is sodium diacetate.

[0055] The preparation method of above-mentioned preservative comprises the following steps:

[0056] (1) prepare yellow peach leaf extract

[0057] The yellow peach leaves are dried and crushed, passed through a mesh sieve, put into an extraction tank, add petroleum ether extraction solvent 2-3 times the weight of the yellow peach leaves, pressurize to 150-200Mpa and maintain the pressure for 10-15min, then release the pressure and filter, the filtrate is placed in The first refrigeration is carried out in the refrigerator, the temperature of the first refrigeration is 0-5°C, and the refrigeration time is 1-2 hours. After the first refrigeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com