Fast charge ternary material positive pole piece and lithium ion battery comprising same

A technology of ternary materials and positive pole pieces, which is applied in the direction of electrode carriers/collectors, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problem of fast charging performance deviation, poor cycle performance, and poor rate performance of ternary positive electrode materials and other issues, to achieve the effect of increasing energy density, improving first-time efficiency, and avoiding the difference in lithium ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

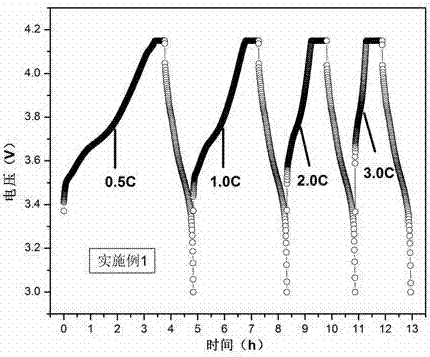

Embodiment 1

[0026] 1) Slurry preparation:

[0027] Add 15g of lithium metal powder, 30g of polymethyl methacrylate, and 50g of graphene into 500g of NMP solvent, and mix evenly to obtain a lithium-supplementing slurry;

[0028] Weigh 5g polyvinylidene fluoride and add it to 150g NMP solvent to disperse evenly, then add 2g graphene conductive agent, 93gLiNi 3 co 5 mn 2 o 2 Ternary material, and stirring to obtain active material slurry;

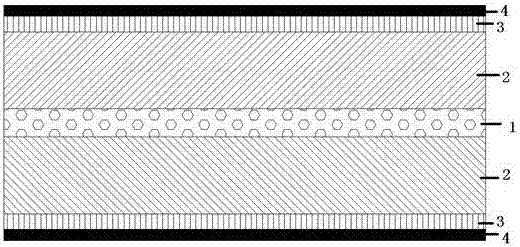

[0029] 2) Preparation of positive composite pole piece:

[0030] In an environment with a dew point ≤ -30°C, the active material slurry is coated on a 20 μm mesh aluminum foil by a coating machine, and the coating thickness is 150 μm. After drying, a pole roll A is obtained. The slurry is coated on the surface of the pole coil A (thickness is 8μm), after drying, the pole coil B is obtained, and then the pole coil is cut into pole pieces and transferred to a tube furnace. Nitrogen gas, and then methane gas was introduced, and the temperature was rais...

Embodiment 2

[0032] 1) Slurry preparation:

[0033] Add 10g of lithium metal powder, 30g of polyethyl methacrylate, and 60g of graphene into 500g of NMP solvent, and mix evenly to obtain a lithium-supplementing slurry;

[0034] Weigh 2g polyvinylidene fluoride and add it to 150g NMP solvent to disperse evenly, then add 3g carbon nanotube conductive agent, 95gLiNi 6 co 2 mn 2 o 2 Ternary material, and stirring to obtain active material slurry;

[0035] 2) Preparation of positive composite pole piece:

[0036] In an environment with a dew point ≤ -30°C, the active material slurry is coated on a 10μm mesh aluminum foil by a coating machine, and the coating thickness is 100μm. After drying, a pole roll A is obtained. The material is coated on the surface of pole roll A (the coating thickness is 5 μm). After drying, the pole roll B is obtained. After that, the pole roll is cut into pole pieces and transferred to a tube furnace. Through the chemical vapor phase method, first pass Nitrogen ...

Embodiment 3

[0038] 1) Slurry preparation:

[0039] Add 20g of lithium metal powder, 40g of polybutylmethacrylate, and 40g of graphene into 500g of NMP solvent, and mix evenly to obtain a lithium-supplementing slurry;

[0040] Weigh 8g polyvinylidene fluoride and add it to 150g NMP solvent to disperse evenly, then add 2g super carbon black conductive agent, 90gLiNi 8 co 1 mn 1 o 2 Ternary material, and stirring to obtain active material slurry;

[0041] 2) Preparation of positive composite pole piece:

[0042] In an environment with a dew point ≤ -30°C, the active material slurry is coated on a 30 μm mesh aluminum foil by a coating machine, and the coating thickness is 200 μm. After drying, a pole roll A is obtained. The material is coated on the surface of the pole roll A with a coating thickness of 10 μm. After drying, the pole roll B is obtained, and then the pole roll is cut into pole pieces and transferred to a tube furnace. Nitrogen gas, then acetylene gas was introduced, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com