Ozone decomposition experiment device

An experimental device and ozone decomposition technology, which are used in separation methods, dispersed particle separation, chemical analysis using catalysis, etc., can solve the problems of low accuracy of experimental results, reduce errors, ensure decomposition effect, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

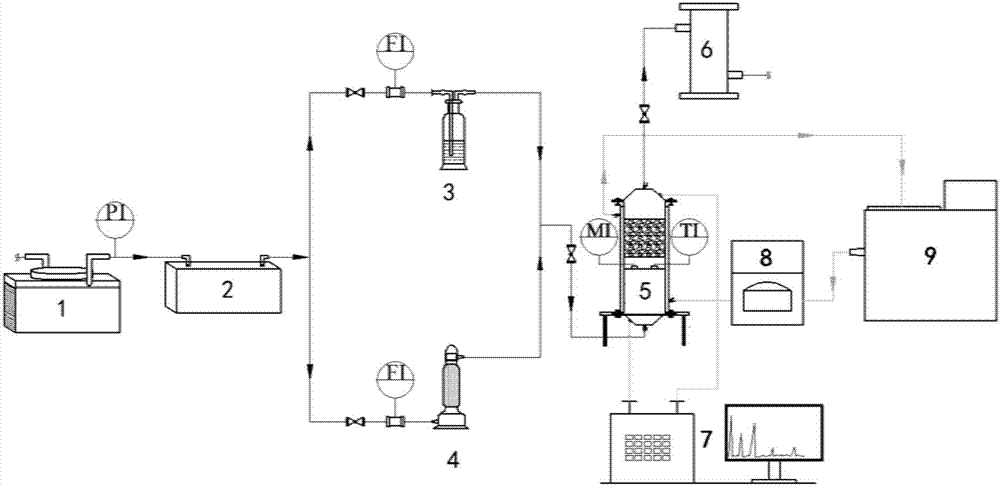

[0035] Such as figure 1 As shown, a kind of ozonolysis experimental device of the present embodiment comprises air pump 1, ozone generating device 2, catalytic reaction tower 5, ozone detection system 7 and for realizing the required sensor and electric control system of function, the air pump 1 The air outlet pipe is connected to the air inlet of the ozone generating device 2, and the air outlet of the ozone generating device 2 is divided into two paths, which are respectively connected to the inlets of the porous gas washing bottle 3 and the gas drying tower 4 through pipelines. The outlet pipelines of the bottle 3 and the gas drying tower 4 are combined and connected to the gas inlet 507 of the catalytic reaction tower 5 . The above-mentioned ozone detection system 7 includes an ozone detector and a computer, and can monitor the ozone concentration of the air inlet 507 and the exhaust outlet 508 of the catalytic reaction tower 5 on-line.

[0036] Deionized water is housed ...

Embodiment 2

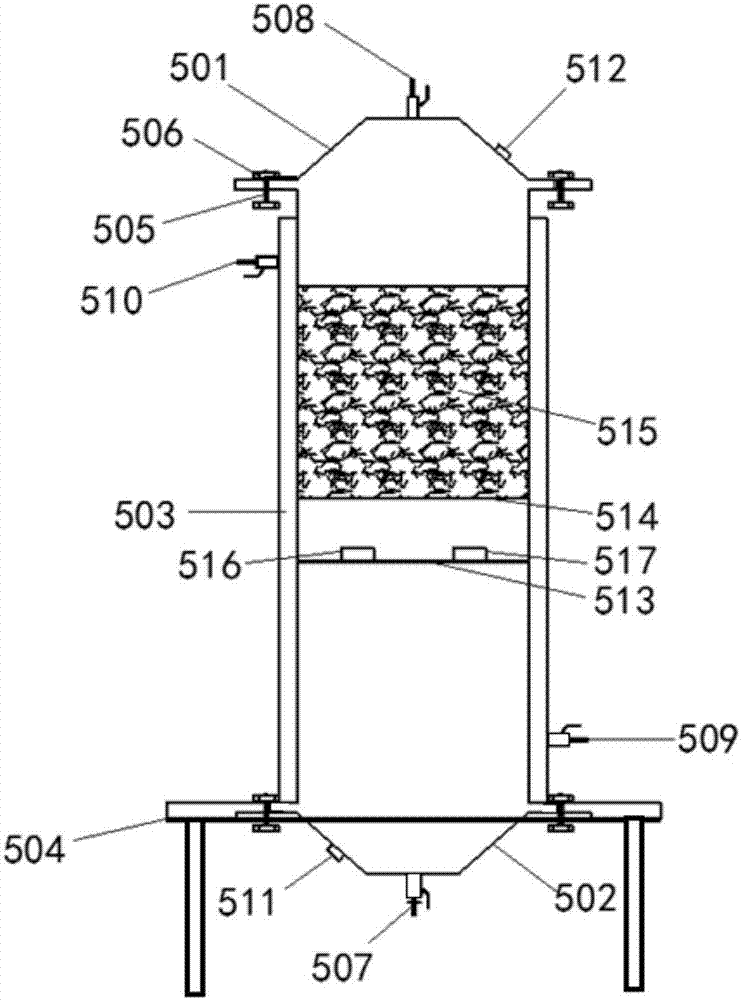

[0041] A kind of ozone decomposition experimental device of this embodiment, its structure is basically the same as embodiment 1, and its difference is: described catalytic reaction tower 5 is installed on the base 504, and the water bath water inlet 509 of its temperature control layer 503 is positioned at catalytic reaction tower 5, the water bath outlet 510 is located at the upper part of the side wall of the catalytic reaction tower 5, and the pipeline between the water bath water inlet 509 and the water bath pot 9 is provided with a peristaltic pump 8. The water bath water inlet 509 can send the water of a certain temperature in the water bath pot 9 into the temperature control layer 503 under the action of the peristaltic pump 8 of the power unit, and when the water level in the temperature control layer 503 exceeds the water bath outlet 510, it will automatically Flow into the water bath 9, the thickness of the temperature control layer 503 in this embodiment is 2cm.

...

Embodiment 3

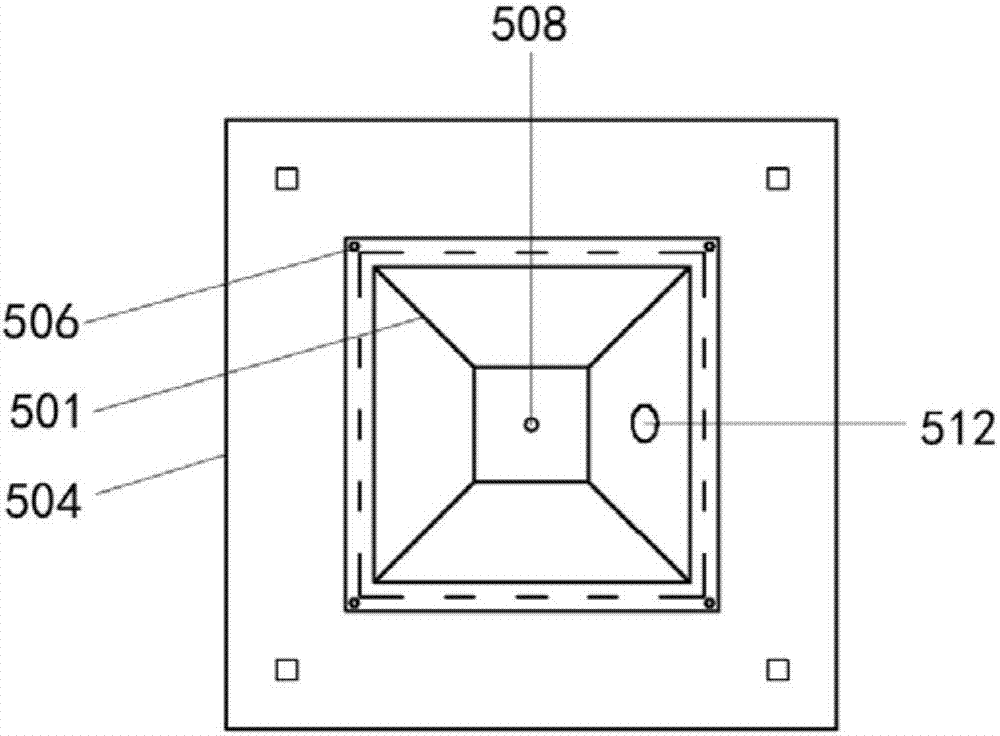

[0044] A kind of ozone decomposition experimental device of present embodiment, its structure is basically the same as embodiment 2, and its difference is: described catalytic reaction tower 5 is provided with sensor support 513 and catalyst support 514, wherein ozone removal catalyst 515 is placed on catalyst support 514 Above, the humidity sensor 516 and the temperature sensor 517 are placed on the sensor bracket 513 and below the catalyst bracket 514 . In the present embodiment, the top of the catalytic reaction tower 5 is provided with a top cover 501, and its bottom is provided with a bottom cover 502, and a gasket 505 is added between the top cover 501 and the bottom cover 502 and the connecting part of the catalytic reaction tower 5 tower body, and Fixing by fastening bolts 506, this connection can ensure the airtightness of the device, help to improve the accuracy of the experimental results, and facilitate disassembly. In this embodiment, the temperature control layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com