Natural gas liquefaction method and device

A liquefaction device and natural gas technology, applied in the field of natural gas liquefaction, can solve problems such as high pressure, heat exchanger damage, and unstable structure, and achieve the effect of effective liquefaction process, improved efficiency, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

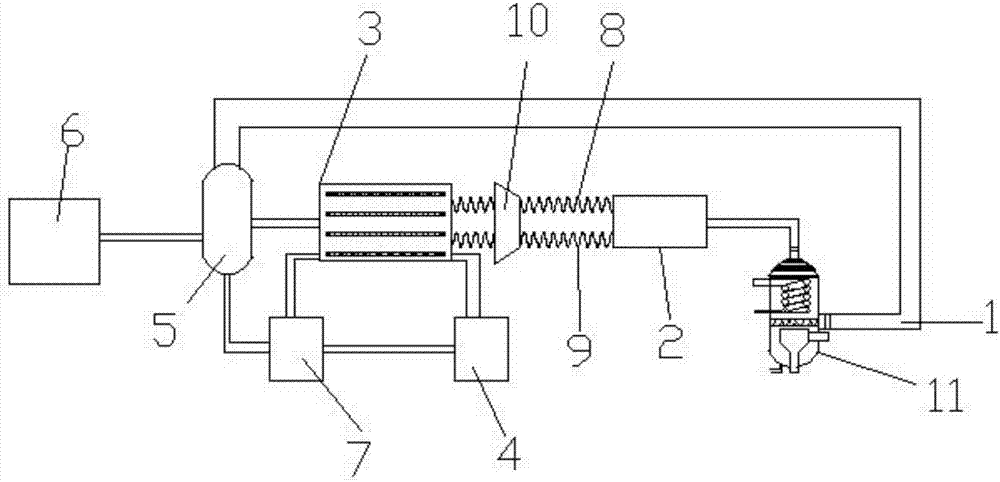

[0040] Refer to attached figure 1 As shown, a natural gas liquefaction device described in this embodiment includes a natural gas inlet pipeline 1, a compressor 2, a heat exchanger 3, a liquid nitrogen storage tank 4, a gas-liquid separator 5, and a liquefied natural gas storage tank 6 , the natural gas inlet pipeline 1 is connected to the compressor 2, the liquid nitrogen storage tank 4 and the compressor 2 are respectively connected to the input end of the heat exchanger 3, and the output ends of the heat exchanger 3 are respectively It is connected with the liquid nitrogen recovery box 7 and the gas-liquid separator 5, and the liquid nitrogen recovery box 7 is connected with the liquid nitrogen storage tank, forming a circulation pipeline as a whole, which is beneficial to the repeated use of liquid nitrogen. Wherein, the gas outlet of the gas-liquid separator 5 communicates with the natural gas inlet pipeline 1, so that the separated gas enters the natural gas inlet pipeli...

Embodiment 2

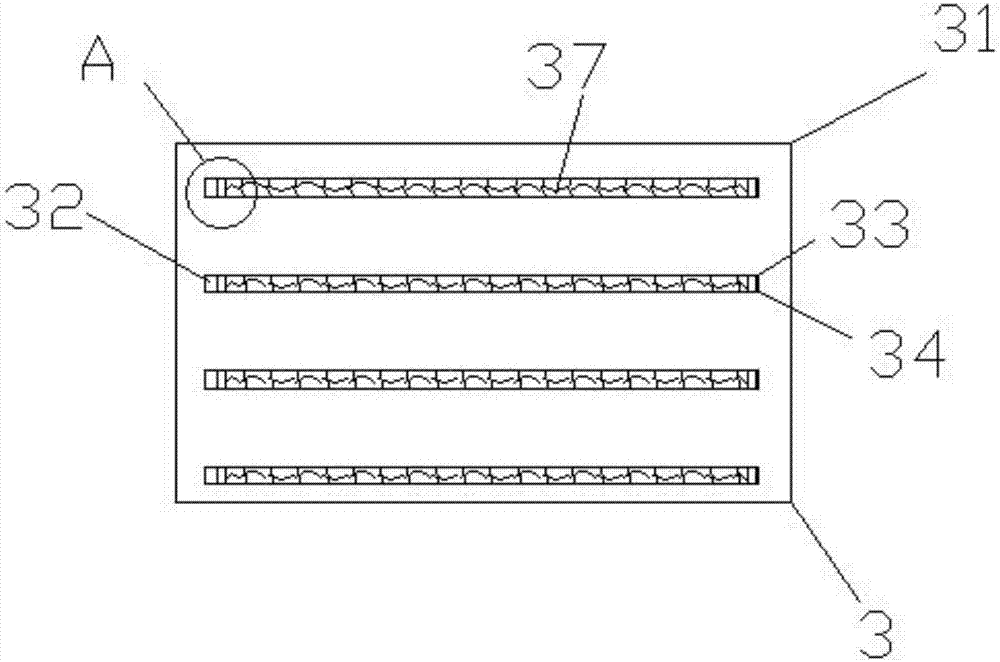

[0044] Refer to attached figure 2 As shown, as a further improvement of the above embodiment, a polyurethane foam layer (not shown in the figure) is provided between the shell 31 of the heat exchanger 3 and the first partition 33 and / or the second partition 34 ;

[0045] Further, when the topmost part of the casing 31 is provided with the first partition 33, the thickness of the polyurethane foam layer is the same as the distance between the inner wall of the casing 31 and the first partition 33; when the bottommost part of the casing 31 is provided with During the second dividing plate 34, then the thickness of polyurethane foam layer is identical with housing 31 bottom insides and the spacing of the second dividing plate 34; Of course, if above-mentioned change the second dividing plate 34 or The principle of the first partition 33 is the same.

[0046] The thermal conductivity of the foamed polyurethane layer is very low, which can reduce the heat loss of the heat exchan...

Embodiment 3

[0051] Refer to attached figure 1 As shown, as a further improvement of Embodiment 1, in this embodiment, the compressor 2 is connected to the heat exchanger 3 through the parallel first spiral hose 8 and the second spiral hose 9, and the first A tapered connecting pipe 10 is provided between the first spiral hose 8 and the second spiral hose 9 .

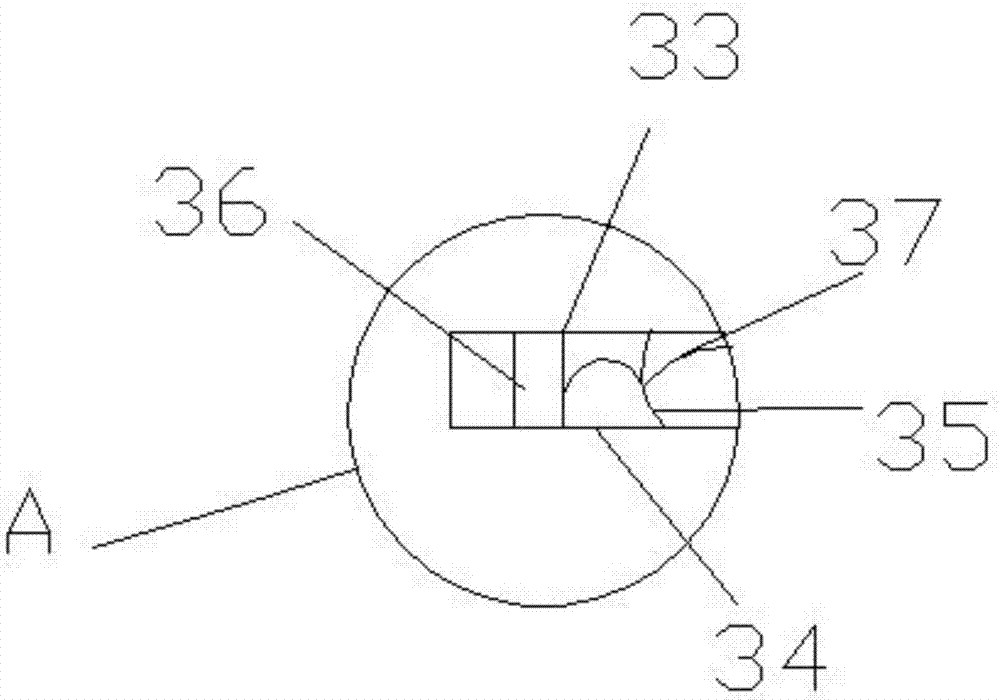

[0052] Due to the impact of the compressed air pulse in the compressor 2, it will cause damage to the fins 35 in the heat exchanger 3, so the flow is shunted out through the spiral hose and buffered by the conical connecting pipe 10, which can reduce the impact and effectively protect the fins 35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com