Preparation method and application of dipotassium tetradiphosphate strontium crystal

A technology of dipotassium strontium tetrametaphosphate and crystal, which is applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, and can solve problems such as the preparation of dipotassium strontium tetrametaphosphate crystals that have not yet been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1——Growing strontium dipotassium tetrametaphosphate crystals in a melt by the Kyropoulos method

[0024] 117.48g (0.85mol) K 2 CO 3 , 125.49g (0.85mol) SrCO 3 and 391.10 g (3.4 mol) NH 4 h 2 PO 4 After grinding and mixing evenly (the molar ratio is K:Sr:P=2:1:4), slowly raise the temperature in the range of 150-300°C to release a large amount of CO produced by the reaction. 2 , NH 3 and H 2 O gas, followed by pre-firing at 400°C for 10 hours. Then put the obtained sample into a Φ60mm×60mm open platinum crucible, put the crucible into a crystal growth furnace, heat up to 900°C to melt the sample, and keep the temperature for 48h to fully escape the gas remaining in the melt to make The melt was homogeneous, and the melt was then cooled to a temperature 2°C above the crystallization temperature. The seed crystal is fixed on the seed crystal rod, introduced into the furnace from the small hole on the top of the growth furnace, and the seed crystal is broug...

Embodiment 2

[0025] Example 2——Growing strontium dipotassium tetrametaphosphate crystals in the melt by pulling method

[0026] 132.24g (1.12mol) KPO 3 and 137.51g (0.56mol) Sr(PO 3 ) 2 After grinding and mixing uniformly (the molar ratio is K:Sr:P=2:1:4), sintering at 600°C for 24 hours. Then put the obtained sample into a Φ60mm×40mm open platinum crucible, put the crucible into the crystal growth pulling furnace, heat up to 800°C to melt the sample, and keep the temperature for 3h to make the melt homogeneous, and then cool down the melt to a temperature 5°C above the crystallization temperature. The seed crystal is fixed on the seed crystal rod, introduced into the furnace through the small hole at the top, and the seed crystal is brought into contact with the liquid surface of the melt to start crystal growth. The seed crystal is rotated at a speed of 30 rpm, and the seed crystal rod is pulled at a rate of 0.5 mm / hour. At the end of the crystal growth, the crystal is removed from ...

Embodiment 3

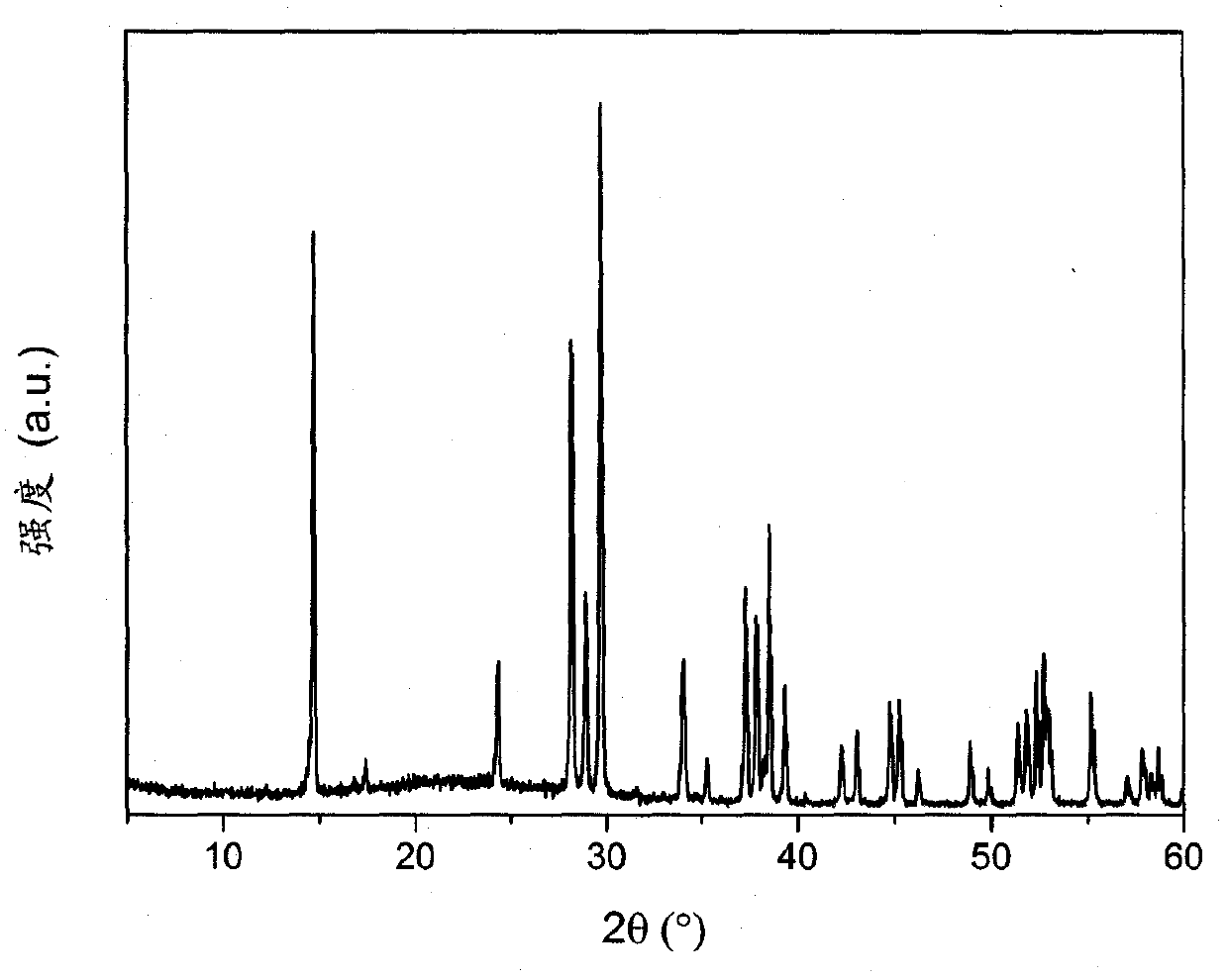

[0028] The crystal of strontium dipotassium tetrametaphosphate prepared in Example 1 is analyzed by single crystal X-ray diffraction structure, as can be seen: the prepared crystal chemical formula is K 2 SrP4 o 12 ; Its crystallographic structure belongs to the tetragonal crystal system, I-4 space group, and the unit cell parameters are Z=2, the unit cell volume is The anionic group in the structure is formed by the phosphorus-oxygen tetrahedron sharing its two oxygen vertices with each other [P 4 o 12 ] 4- cyclic anion. Carry out powder X-ray diffraction test to the prepared strontium dipotassium tetrametaphosphate crystal, and its diffraction spectrum is as follows figure 1 shown.

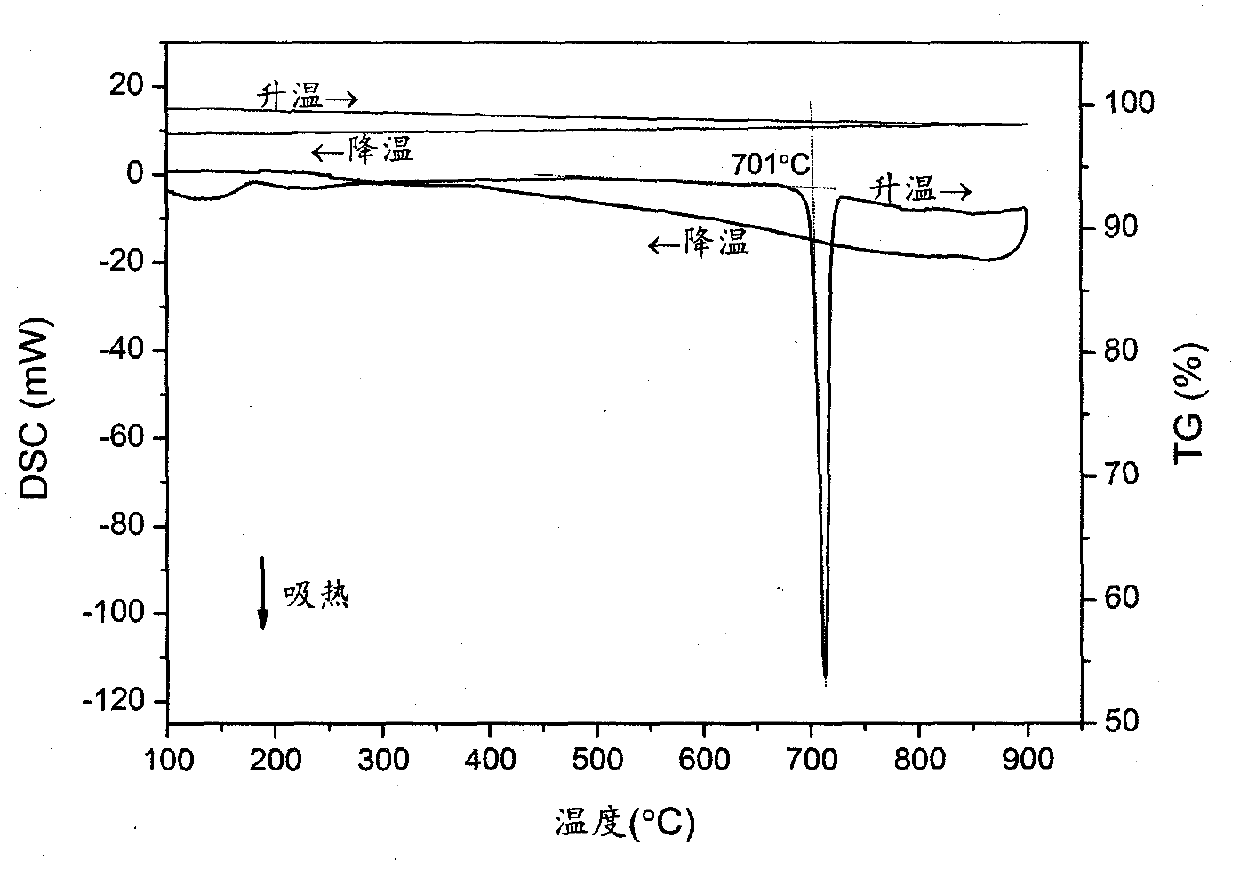

[0029] Carry out DSC-TG analysis to the prepared strontium dipotassium tetrametaphosphate crystal, the result is as follows figure 2 shown. It can be seen from the figure that the melting point of the crystal is about 701°C, and there is no obvious thermal weight loss below 900°C, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com