A kind of cleaning agent for aluminum alloy mold with corrosion inhibition effect

An aluminum alloy and cleaning agent technology, which is applied in the field of aluminum product processing, can solve the problems affecting the product quality, the service life of the mold, the normal use of the aluminum alloy mold, and the surface corrosion of the aluminum alloy mold, so as to achieve low production cost, good use effect, Fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

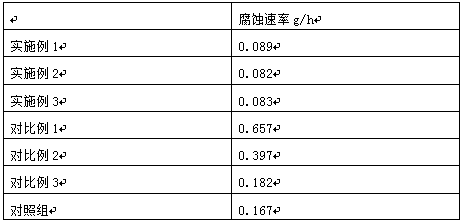

Embodiment 1

[0021] An aluminum alloy mold cleaner with corrosion inhibition effect, which is made of the following ingredients in parts by weight: polyglycolic acid 5, zinc ricinoleate 6, inositol 2, glycine 1, corrosion inhibitor 2.35, water 80;

[0022] The corrosion inhibitor is made of the following components in parts by weight: 1.23 urotropine, 3.5 modified water chestnut starch, 0.14 garlic oil, and 0.36 sodium dodecylbenzenesulfonate;

[0023] The preparation method of the modified water chestnut starch is:

[0024] (1) Mix and dissolve sodium montmorillonite and deionized water at a mass ratio of 1:5, then add polyethylene glycol twice the mass of sodium montmorillonite, and stir at 800r / min for 30min to form a suspension ;

[0025] (2) Heat 800-mesh water chestnut starch with 200W microwave for 2 minutes, put it in the impregnation tank, and carry out vacuum treatment; introduce the sodium-based montmorillonite suspension into the impregnation tank to soak the water chestnut s...

Embodiment 2

[0036] An aluminum alloy mold cleaner with corrosion inhibition effect, which is made of the following components in parts by weight: polyglycolic acid 8, zinc ricinoleate 10, inositol 4, glycine 3, corrosion inhibitor 2.46, water 90;

[0037] The corrosion inhibitor is made of the following components in parts by weight: urotropine 1.26, modified water chestnut starch 3.8, garlic oil 0.16, sodium dodecylbenzene sulfonate 0.38;

[0038] The preparation method of the modified water chestnut starch is:

[0039] (1) Mix and dissolve sodium montmorillonite and deionized water at a mass ratio of 1:5, then add polyethylene glycol twice the mass of sodium montmorillonite, and stir at 800r / min for 30min to form a suspension ;

[0040] (2) Heat 800-mesh water chestnut starch with 200W microwave for 2 minutes, put it in the impregnation tank, and carry out vacuum treatment; introduce the sodium-based montmorillonite suspension into the impregnation tank to soak the water chestnut star...

Embodiment 3

[0051] An aluminum alloy mold cleaner with corrosion inhibition effect, which is made of the following components in parts by weight: polyglycolic acid 6, zinc ricinoleate 8, inositol 3, glycine 2, corrosion inhibitor 2.38, water 85;

[0052] The corrosion inhibitor is made of the following components in parts by weight: urotropine 1.25, modified water chestnut starch 3.6, garlic oil 0.15, sodium dodecylbenzene sulfonate 0.37;

[0053]The preparation method of the modified water chestnut starch is:

[0054] (1) Mix and dissolve sodium montmorillonite and deionized water at a mass ratio of 1:5, then add polyethylene glycol twice the mass of sodium montmorillonite, and stir at 800r / min for 30min to form a suspension ;

[0055] (2) Heat 800-mesh water chestnut starch with 200W microwave for 2 minutes, put it in the impregnation tank, and carry out vacuum treatment; introduce the sodium-based montmorillonite suspension into the impregnation tank to soak the water chestnut starch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com