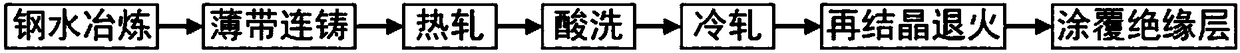

A method for preparing thin gauge products of high magnetic induction non-oriented silicon steel based on thin strip continuous casting

A technology of oriented silicon steel and high magnetic induction, which is applied in the field of metallurgy, can solve problems such as inability to mass-produce and affect the lamination coefficient, and achieve the effects of reducing high-frequency iron loss, increasing production rhythm, and improving recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the method for preparing thin gauge products of high magnetic induction non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0033] The molten steel is smelted according to the set composition, and its composition by weight percentage is: C 0.006%, Si 2.0%, Mn 0.4%, Al 0.003%, P 0.04%, S 0.0025%, and the balance is Fe;

[0034] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1230°C, the superheat is controlled at 30°C, the molten steel enters the strip continuous casting machine through the tundish, the liquid level is controlled at 120mm, and the casting speed is 60m / min, a molten pool is formed and solidified in the crystallizer composed of rotating casting rolls and side sealing plates, and the thickness of the casting strip is 1.5mm;

[0035] After the cast strip is taken out of the roll, it is cooled t...

Embodiment 2

[0040] In this embodiment, the method for preparing thin gauge products of high magnetic induction non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0041] Smelting molten steel according to the set composition, its composition by weight percentage is: C 0.0052%, Si 2.2%, Mn0.35%, Al 0.003%, P 0.05%, S 0.0022%, and the balance is Fe;

[0042] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1230°C, the superheat is controlled at 30°C, the molten steel enters the strip continuous casting machine through the tundish, the liquid level is controlled at 120mm, and the casting speed is 60m / min, a molten pool is formed and solidified in the crystallizer composed of rotating casting rolls and side sealing plates, and the thickness of the casting strip is 1.5mm;

[0043] After the cast strip is taken out of the roll, it is cooled to 950°C a...

Embodiment 3

[0047] In this embodiment, the method for preparing thin gauge products of high magnetic induction non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0048] Smelting molten steel according to the set composition, its composition by weight percentage is: C 0.004%, Si 3.0%, Mn 0.2%, Al 0.0015%, P 0.03%, S 0.0018%, and the balance is Fe;

[0049] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1250°C, the superheat is controlled at 20°C, the molten steel enters the thin strip continuous casting machine through the tundish, the liquid level is controlled at 100mm, and the casting speed is 70m / min, a molten pool is formed and solidified in the crystallizer composed of rotating casting rolls and side sealing plates, with a thickness of 1.2mm;

[0050] After the cast strip is taken out of the roll, it is cooled to 900°C at a rate of 70°C / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com