A kind of purification method of mtgase crude enzyme

A purification method and crude enzyme technology, applied in the field of MTGase crude enzyme purification, can solve the problems of low sample recovery rate, high cost and complicated process, and achieve the effect of high enzyme activity recovery rate, high enzyme activity and simplified process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

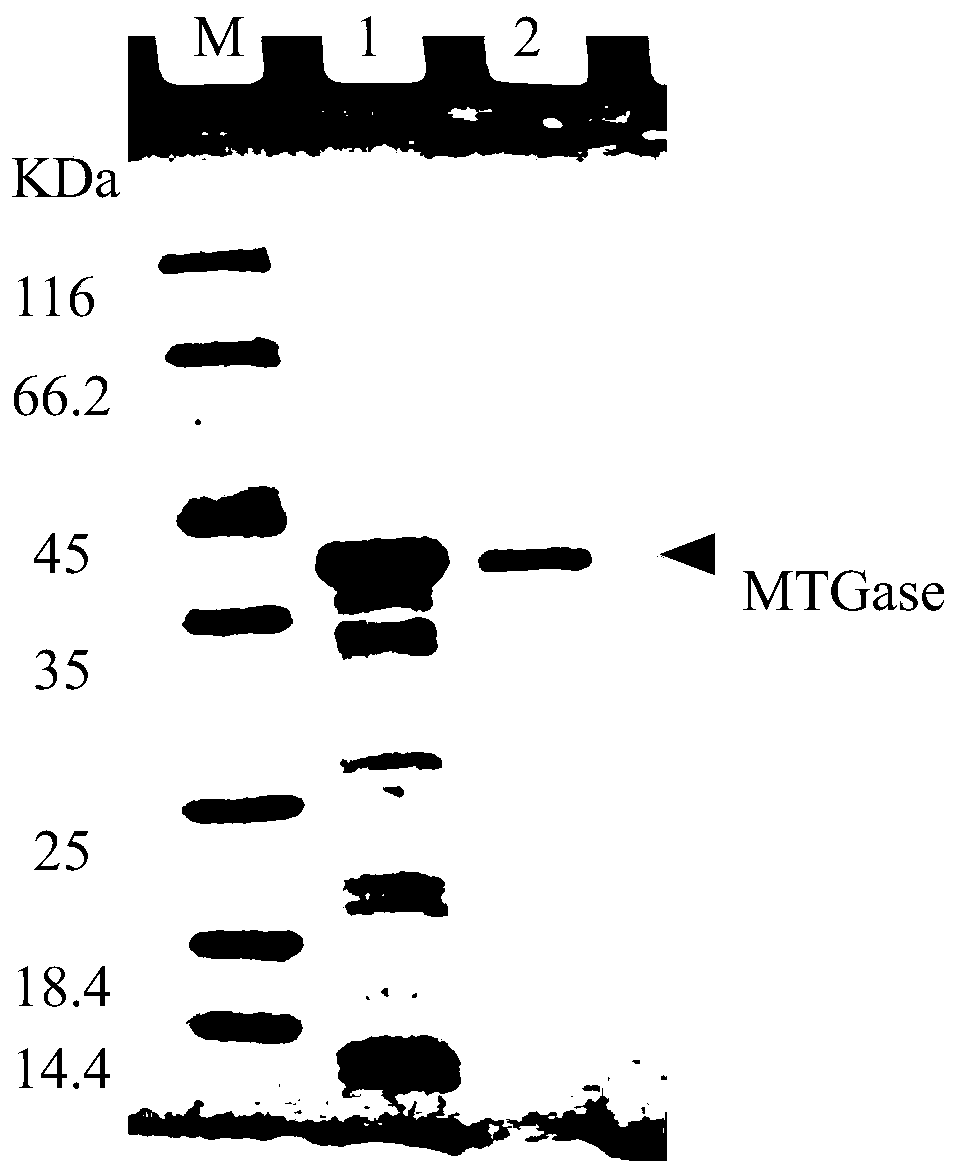

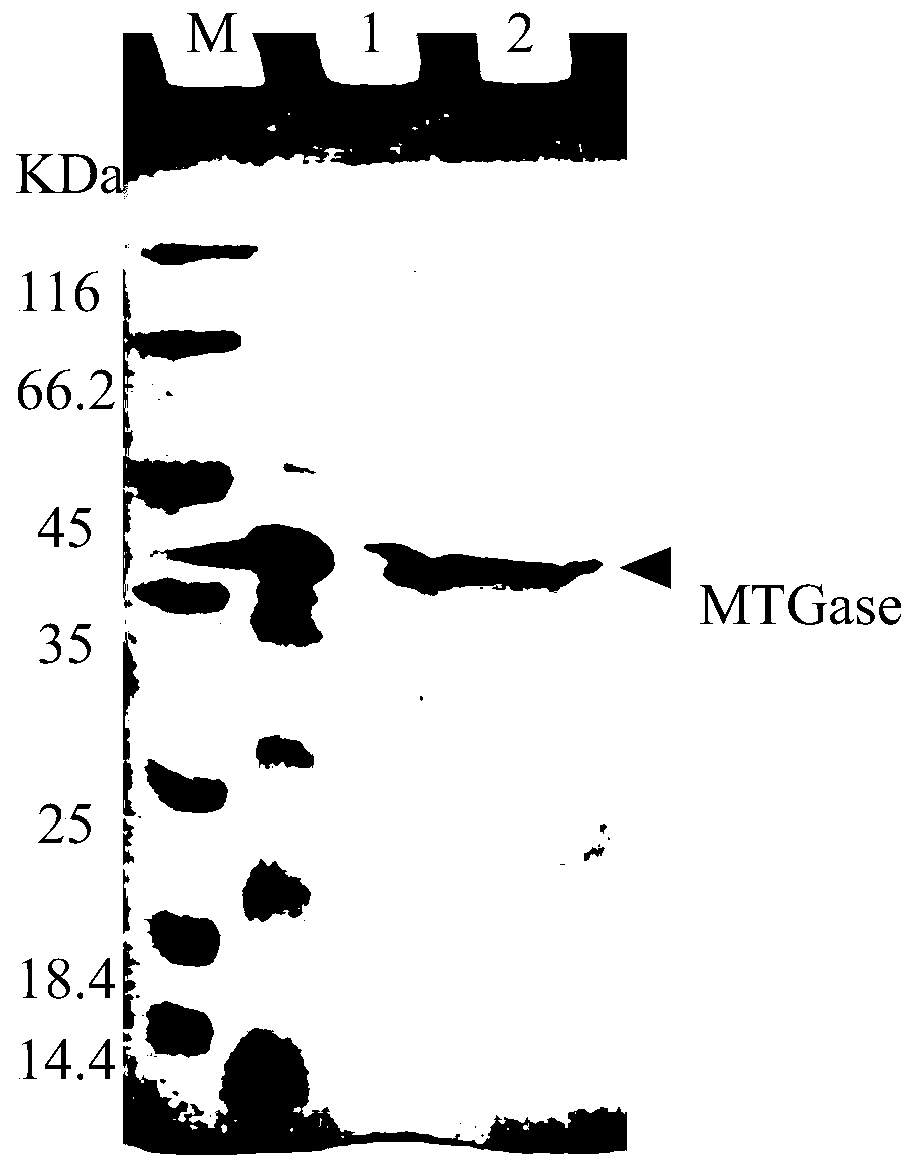

Image

Examples

Embodiment 1

[0030] The purification method of MTGase crude enzyme, comprises the following steps:

[0031] The crude enzyme powder of MTGase is dissolved in water, is mixed with 2wt% MTGase crude enzyme liquid;

[0032] Prepare PEG-6000 / (NH 4 ) 2 SO 4 A two-phase aqueous solution consisting of:

[0033] PEG-6000 27wt%

[0034] (NH 4 ) 2 SO 4 13wt%

[0035] Water 60wt%;

[0036] PEG-6000 / (NH 4 ) 2 SO 4 The two-phase aqueous solution forms the PEG-6000 phase of the upper layer and the salt phase of the lower layer;

[0037] Mix MTGase crude enzyme solution with PEG-6000 / (NH 4 ) 2 SO 4 The aqueous two-phase solution was mixed uniformly according to the mass ratio of 1:5, and stood at 30°C for 1 h, MTGase entered the salt phase in the two-phase system, and collected the salt phase in the two-phase system;

[0038] The collected salt phase was pumped into the nanofiltration membrane equipment for processing. The nanofiltration membrane material used was polyacrylonitrile, the ...

Embodiment 2

[0040]The purification method of MTGase crude enzyme, comprises the following steps:

[0041] The crude enzyme powder of MTGase is dissolved in water, is mixed with 2wt% MTGase crude enzyme liquid;

[0042] Prepare PEG-8000 / (NH 4 ) 2 SO 4 A two-phase aqueous solution consisting of:

[0043] PEG-10000 30wt%

[0044] (NH 4 ) 2 SO 4 12wt%

[0045] Water 58wt%;

[0046] PEG-8000 / (NH 4 ) 2 SO 4 The two-phase aqueous solution forms the PEG-8000 phase of the upper layer and the salt phase of the lower layer;

[0047] Mix MTGase crude enzyme solution with PEG-8000 / (NH 4 ) 2 SO 4 The aqueous two-phase solution was mixed uniformly according to the mass ratio of 1:5, and stood at 20°C for 1 h, MTGase entered the salt phase in the two-phase system, and collected the salt phase in the two-phase system;

[0048] The collected salt phase was pumped into the nanofiltration membrane equipment for processing. The nanofiltration membrane material used was polyacrylonitrile, the ...

Embodiment 3

[0050] The purification method of MTGase crude enzyme, comprises the following steps:

[0051] The crude enzyme powder of MTGase is dissolved in water, is mixed with 1.8wt% MTGase crude enzyme liquid;

[0052] Prepare PEG-10000 / (NH 4 ) 2 SO 4 A two-phase aqueous solution consisting of:

[0053] PEG-10000 25wt%

[0054] (NH 4 ) 2 SO 4 20wt%

[0055] Water 55wt%;

[0056] PEG-10000 / (NH 4 ) 2 SO 4 The two-phase aqueous solution forms the PEG-10000 phase of the upper layer and the salt phase of the lower layer;

[0057] Mix MTGase crude enzyme solution with PEG / (NH 4 ) 2 SO 4 The aqueous two-phase solution was mixed uniformly according to the mass ratio of 1:3, and stood at 40°C for 1 h, MTGase entered the salt phase in the two-phase system, and collected the salt phase in the two-phase system;

[0058] The collected salt phase was pumped into the nanofiltration membrane equipment for processing. The nanofiltration membrane material used was polyacrylonitrile, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com