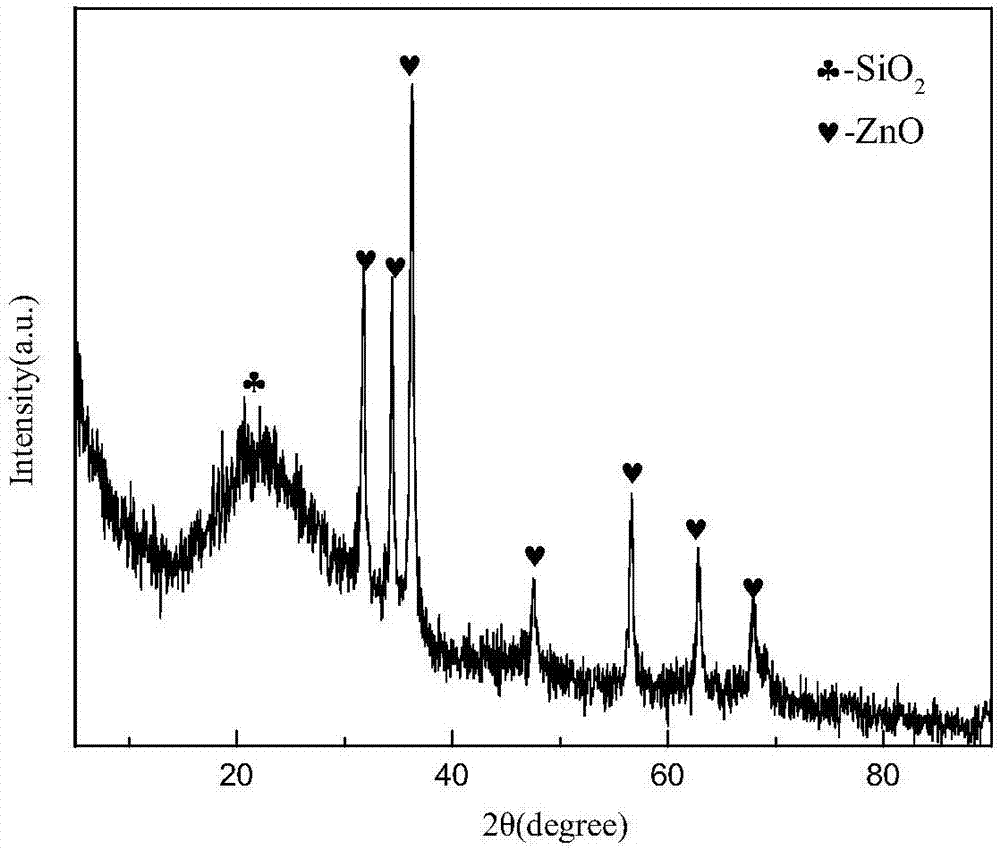

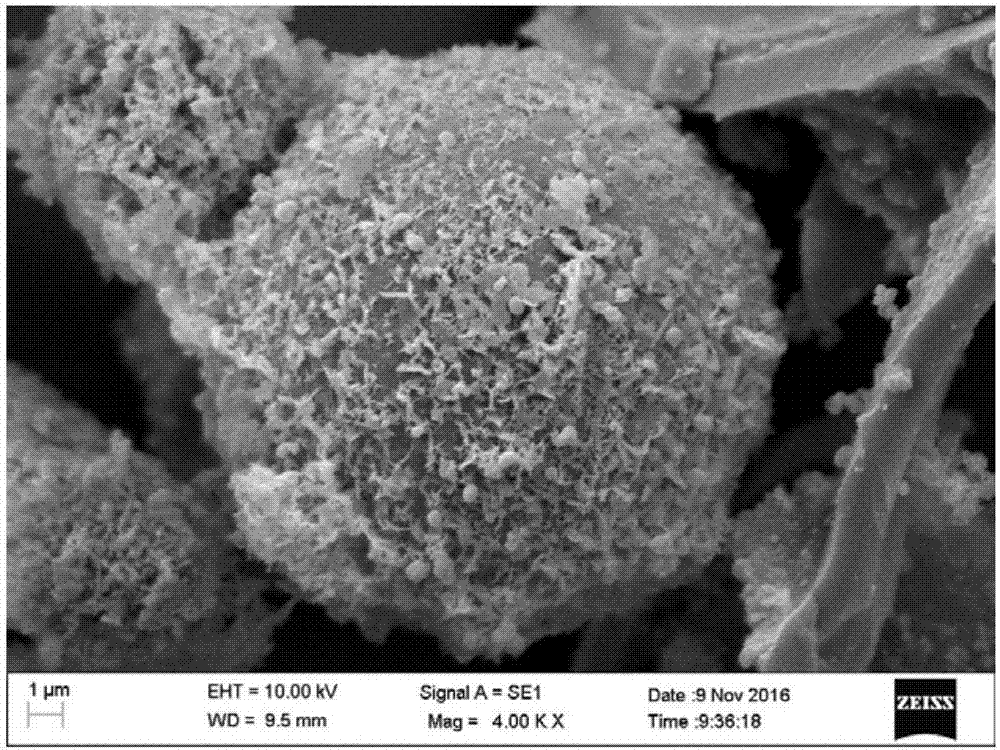

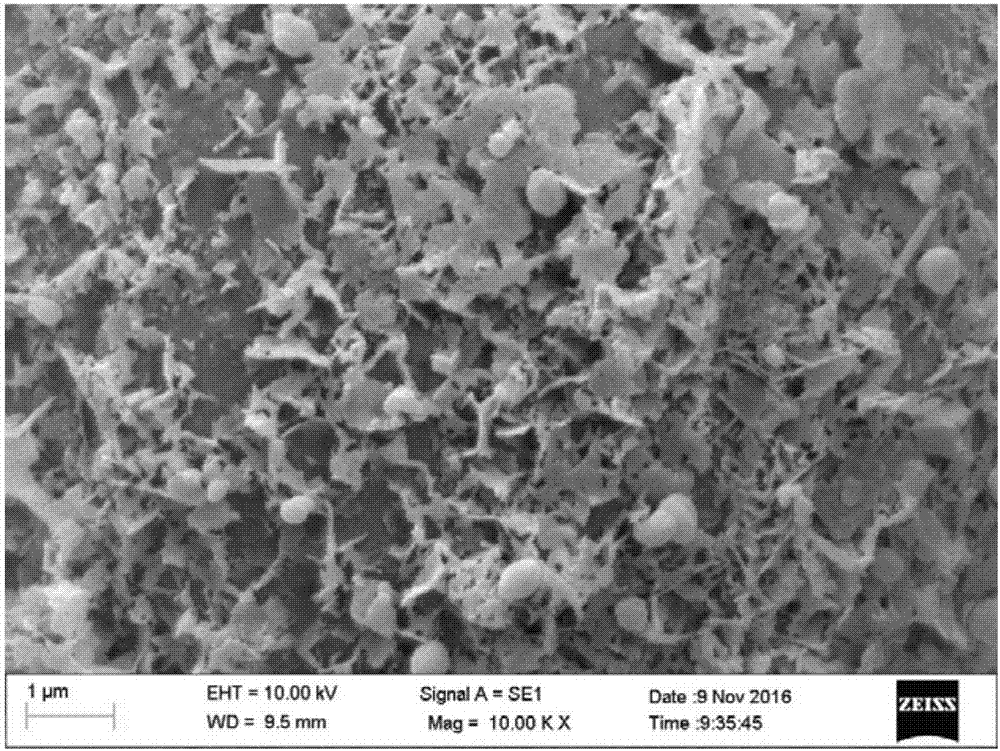

Zinc oxide nanosheet-coated hollow glass bead photocatalytic reflection composite pigment and synthetic method thereof

A technology of hollow glass microspheres and zinc oxide nanometers, which is applied in the field of inorganic pigments, can solve problems affecting photocatalytic effects, and achieve the effects of reducing air-conditioning energy consumption, high solar reflectance, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for synthesizing zinc oxide nanosheet-coated hollow glass micropearl photocatalytic reflective composite pigments, comprising the following steps:

[0027] (1) Add 10g of hollow glass microspheres to 150ml of 10% sodium hydroxide solution and stir for 12h to filter and dry for later use; 0.52g of zinc nitrate and 0.4g of sodium hydroxide are dissolved in 78.4g of isopropanol respectively In, liquid A and liquid B were obtained respectively.

[0028] (2) Add the hollow glass microspheres pretreated in step 1 to the mixture of liquid A and liquid B at a volume ratio of 4:1, keep stirring for 15 minutes, filter, dry at 90°C for 12 hours, and then calcinate at 400°C After 1 h, a sample of zinc oxide seeds loaded on hollow glass microspheres was obtained.

[0029] (3) Add the calcined sample to the growth solution that is fully mixed with 7.44g of zinc nitrate, 4.78g of triethanolamine and 500g of distilled water, keep stirring at 90°C for 6h, filter, and dry at 90...

Embodiment 2

[0043] A method for synthesizing zinc oxide nanosheet-coated hollow glass micropearl photocatalytic reflective composite pigments, comprising the following steps:

[0044] (1) Add 5 g of hollow glass microspheres to 150 ml of 10% sodium hydroxide solution, stir for 12 h, filter and dry for later use. Dissolve 0.52g of zinc nitrate and 0.4g of sodium hydroxide in 78.4g of isopropanol and divide them into liquid A and liquid B.

[0045] (2) Add the pretreated hollow glass microspheres to the mixture of A and B mixed at a volume ratio of 4:1, continue to stir for 15 minutes, filter and dry at 90°C for 12h, and then calcinate at 400°C for 0.5h to obtain hollow glass microspheres. Bead-loaded ZnO seed samples.

[0046] (3) Add the calcined sample to the growth solution that is fully mixed with 7.44g of zinc nitrate, 4.78g of triethanolamine and 500g of distilled water, keep stirring at 90°C for 6h, filter, and dry at 90°C for 12h to obtain zinc oxide Nanosheet-coated hollow glass...

Embodiment 3

[0048] A method for synthesizing zinc oxide nanosheet-coated hollow glass micropearl photocatalytic reflective composite pigments, comprising the following steps:

[0049] (1) Add 10 g of hollow glass microspheres into 150 ml of 10% sodium hydroxide solution, stir for 12 h, filter and dry for later use. Dissolve 0.52g of zinc nitrate and 0.4g of sodium hydroxide in 78.4g of isopropanol and divide them into liquid A and liquid B.

[0050] (2) Add the pretreated hollow glass microspheres to the mixture of A and B mixed at a volume ratio of 2:1, continue to stir for 15 minutes, filter and dry at 90°C for 12h, and then calcinate at 400°C for 0.5h to obtain hollow glass microspheres. Bead-loaded ZnO seed samples.

[0051] (3) Add the calcined sample to the growth solution that is fully mixed with 7.44g of zinc nitrate, 4.78g of triethanolamine and 500g of distilled water, keep stirring at 80°C for 6h, filter, and dry at 90°C for 12h to obtain zinc oxide Nanosheet-coated hollow gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com