Method for treating high-concentration cassava alcohol wastewater by continuous full-mixing anaerobic reaction

A technology of cassava alcohol and anaerobic reaction, which is applied in anaerobic digestion treatment, special treatment targets, natural water treatment, etc., can solve the problem of difficult handling of suspended solids, achieve high-value utilization, improve processing capacity, and increase production The effect of volume and utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

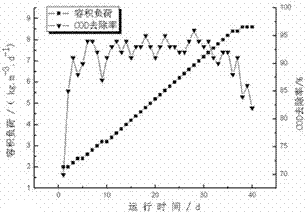

Embodiment 1

[0031] ⑴ Select water quality

[0032] The waste liquid discharged from the alcohol distillation tower is used as the treated water. The COD content in the waste water is relatively high, and the carbon, nitrogen, and phosphorus elements can meet the requirements of microorganisms for nutrients, and there is no need to add additional nutrients; the technical index of water quality is: bad liquid The temperature is as high as ±90 ℃, and the water quality is COD (mg / L) 20000-60000, pH3.0-6.0, SS (g / L) 25-40.

[0033] ⑵Operation method

[0034] a. Start the system at 55°C;

[0035] b. Add sludge to the water quality according to the volume ratio, and add 4% of the dry weight of the sludge, put the sludge with a water content of 75.6% into the system reactor, and cultivate the sludge for 1 day for domestication;

[0036] c. On the second day, the cassava alcohol wastewater was added to the fully mixed anaerobic reactor for hydraulic agitation and mixing through the circulation p...

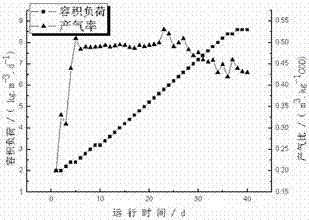

Embodiment 2

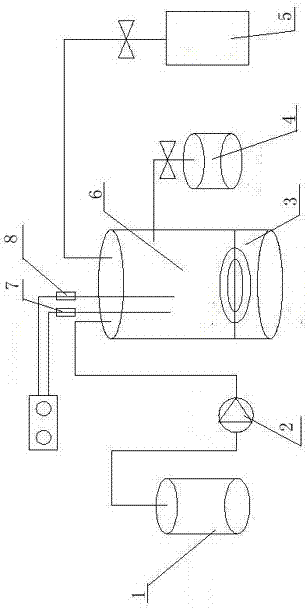

[0045] The method utilizes a system capable of continuous feeding to treat waste water, and the treated water becomes standard water, and at the same time biogas is obtained. For the structure of the system, see figure 1 , including four parts: continuous feeder 1, feed pump 2, anaerobic reactor 3, liquid outlet device 4, biogas collection device 5 and temperature pH electrode. The total volume of the reactor is 5000M³, of which 4500M³ is used to treat wastewater, and the upper 500M³ is used to store digested biogas, and the hydraulic circulation system that comes with the tank is used for material mixing. Use direct heating and heat exchange system to maintain the temperature at 55 °C. Wastewater enters the reactor from the feed system through the feed pump.

[0046] The operation steps are as follows:

[0047] a. Start the system at 58°C;

[0048]b. Add sludge to the water according to the volume ratio of 6% of the dry weight of the sludge, and inject the sludge with a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com