Preparation method of fleecy fabric anti-layering foam sandwich composite material board

A composite material and anti-delamination technology, applied in the field of composite materials, can solve the problems of poor product quality consistency, low degree of standardization, and more manual participation, and achieve the effects of designable mechanical properties, simple molding process, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a fleece fabric anti-delamination foam sandwich composite material plate, comprising the following steps:

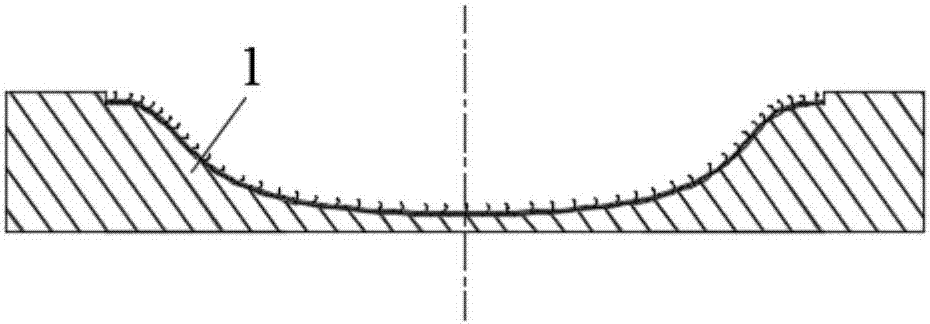

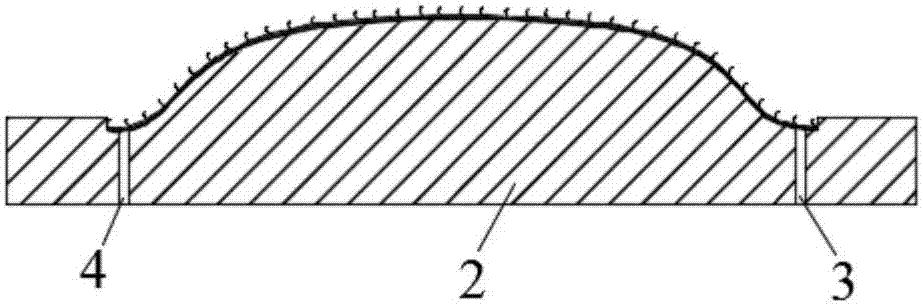

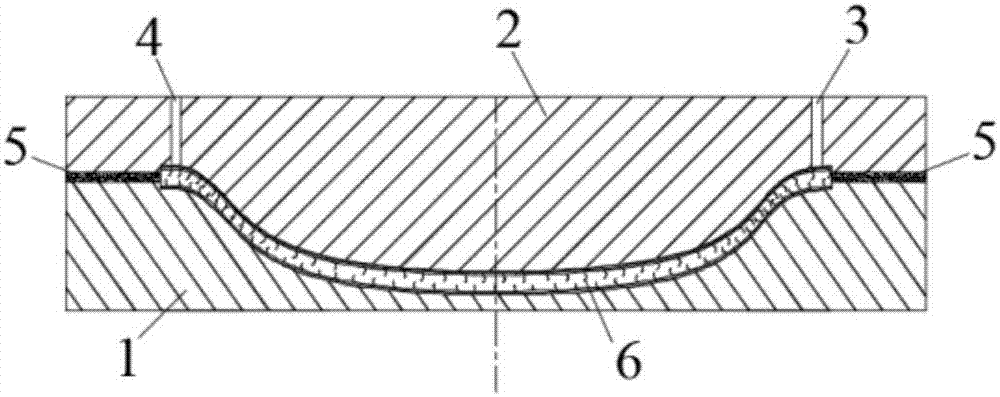

[0031] Step 1: Refer to attached figure 1 and attached figure 2 , make two molds with complementary curved surfaces, respectively as the upper mold 2 and the lower mold 1, wherein the upper mold 2 is a convex mold, and two through holes are opened on the upper mold 2, one of which is used as a foaming glue inlet 3. The other through hole is used as a foaming glue outlet 4. The diameter of the two through holes is 5mm, and the inner and outer surface outlets of the through holes are chamfered or rounded.

[0032] Step 2: Apply release agent on the surface of the concave mold, then apply gel coat, and spread the carbon fiber single-sided fleece fabric on the mold—the smooth surface of the carbon fiber fabric is laid on the surface of the concave mold, and the pile surface is open to the concave mold On one side, use a brush to pick up the r...

Embodiment 2

[0041] A method for preparing a fleece fabric anti-delamination foam sandwich composite material plate, comprising the following steps:

[0042] Step 1: Make two molds with complementary profiles, which are respectively used as upper mold 2 and lower mold 1, wherein the upper mold 2 is a concave mold, and two through holes are opened on the upper mold 2, one of which is used as a foaming inlet The glue port 3, the other through hole is used as the foaming glue outlet 4, the diameter of the two through holes is 20mm, and the inner and outer surface outlets of the through holes are chamfered or rounded;

[0043] Step 2: Lay a release cloth on the surface of the concave mold, then apply gel coat, and spread the glass fiber single-sided fleece fabric on the mold—the smooth surface of the glass fiber fleece fabric is laid on the surface of the concave mold, and the pile surface Facing the open side of the concave mold, use a brush to pick up the resin mixture containing the curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com