Device and method for processing circular single dovetail grooves in back surfaces of ceramic tiles

A processing device and dovetail groove technology, applied in the direction of unloading device, manufacturing tool, forming pressure head, etc., can solve the problems of fragile tiles, large demand, danger, etc., achieve simple and effective pressure maintenance, increase forming speed, improve The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

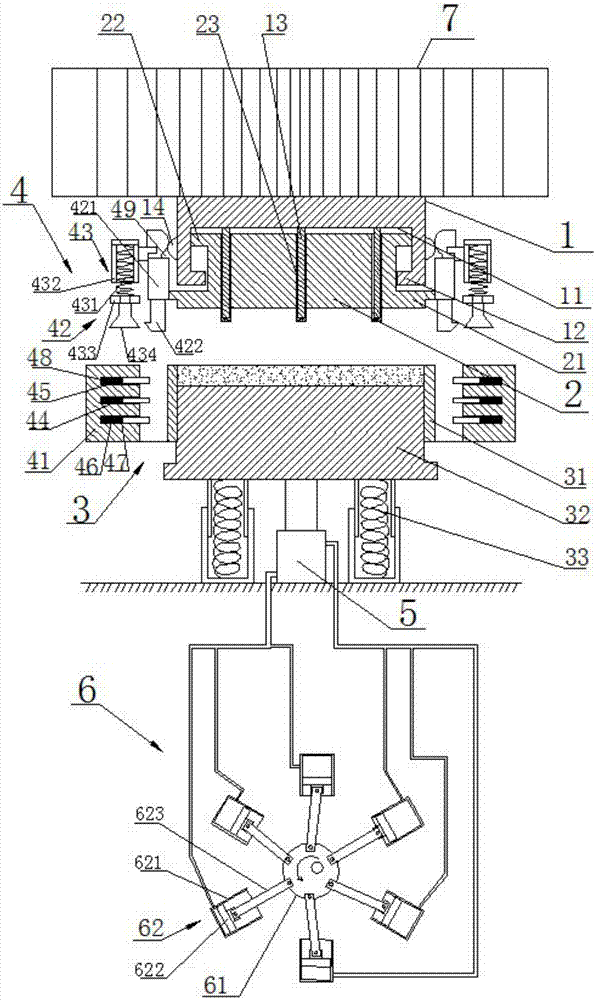

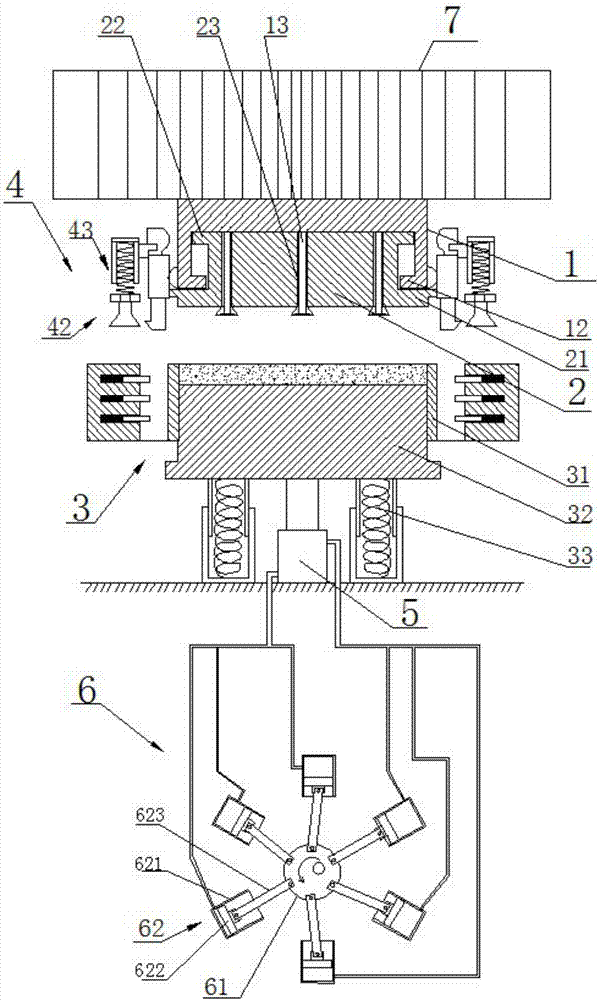

[0047] see figure 1 , 2 , 9, 10, 11, 12; a processing device for a circular single dovetail groove on the back of a ceramic tile, comprising a hollow pressure seat lifting cover 1 fixed at the lower end of the air hammer 7 and a sliding sleeve matching with the pressure seat lifting cover 1 The press seat 2; the upper end of the press seat lifting cover 1 is provided with a cover surface 11, and the lower end is provided with an inwardly extending lifting arm 12; The upper end of the pressure plate 21 is provided with a lifted arm 22 that extends outwards and is located in the lifting cover 1 of the pressure seat; the lifted arm 22 is limited and slid in the cavity formed by the cover surface 11 and the lifting arm 12; A plurality of hollow cylinders 23 are evenly distributed on the press seat 2; the upper end of the hollow cylinders 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com