Detachable combined notch template and application method thereof

A combination and formwork technology, applied in the field of aviation manufacturing engineering, can solve the problems of unfavorable on-site workers' operation and handling, heavy weight, inconvenient use, etc., and achieve the effect of humanized on-site operation, light weight and clear functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

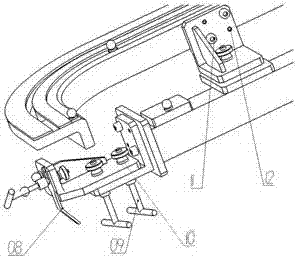

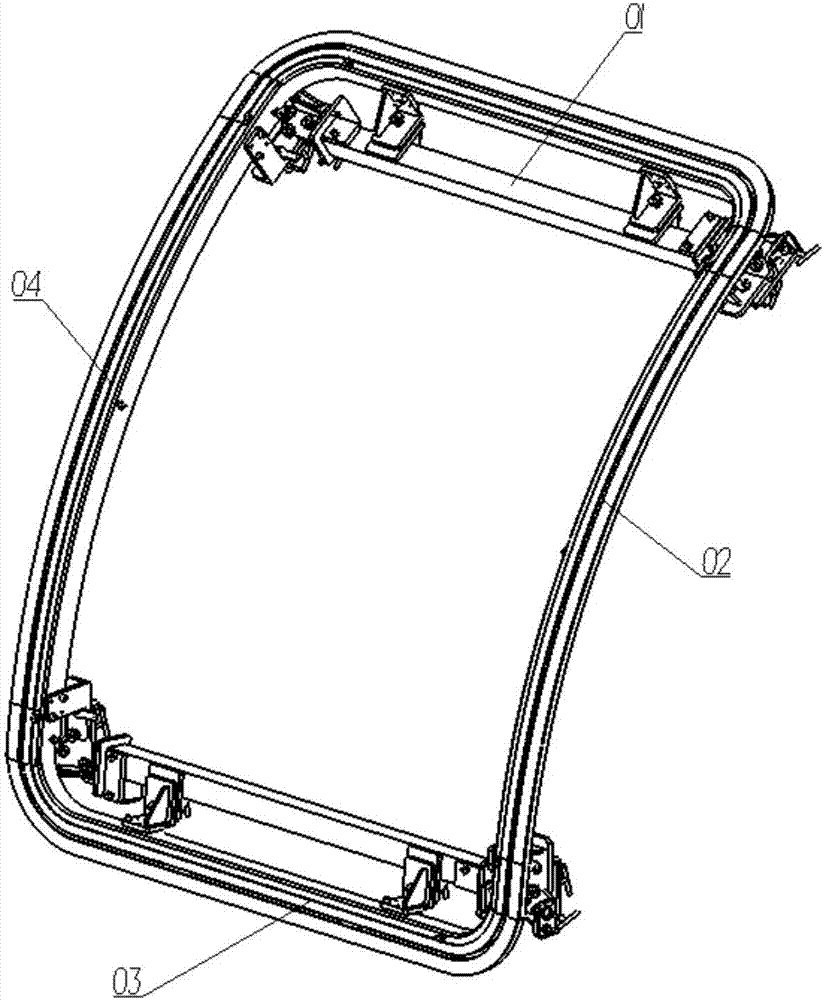

[0039]A detachable combined incision template, including four milling template components, the upper milling template component 1 and the lower milling template component 3 are symmetrical, the two have the same structure, the right milling template component 2 and the left milling template Component 4 is symmetrical, and both have the same structure.

[0040] The four milling template components described form a continuous closed loop, and each adjacent two milling template components share a positioning reference hole, that is, a total of 4 positioning reference holes, and each positioning reference hole is respectively milled by two pieces Each formwork component is used once, so as to realize the separate use of 4 milling formwork components; when the four milling formwork components are used separately, the door frame skin of a certain distance is milled, and the four parts of the milled door frame skin can form a A complete closed loop completes the milling of the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com