A continuous preparation process of aluminum foam pellets with advanced pore shape

A preparation process, aluminum foam technology, applied in the field of foam metal material preparation, can solve the problems of difficult to ensure product performance and structure reproducibility, difficult to meet, high requirements, etc., to ensure structure reproducibility and performance uniformity, equipment footprint Small, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

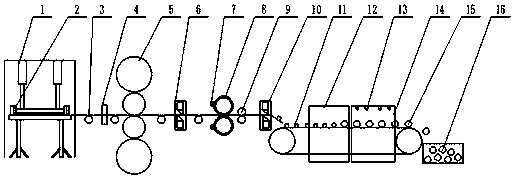

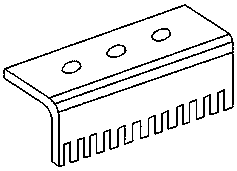

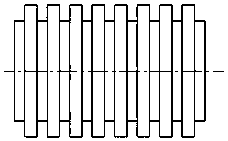

[0034] Such as figure 1 , figure 2 with image 3 As shown, the present invention is a continuous preparation process of aluminum foam pellets with advanced pore shape. The entire preparation system consists of a powder hot pressing area, a prefabricated plate hot rolling area, a cutting area, a foaming area and an atomization area. Concrete preparation process comprises the following steps:

[0035] (1) Powder hot pressing: add Al powder, Si powder, Mg powder and TiH powder with a certain mass ratio to the feeding port 2 Powder mixed powder, in which Al powder accounts for 83-91% by mass fraction, Si powder accounts for 7-15% by mass fraction, Mg powder accounts for about 1%, and TiH 2 Powder accounts for about 0.6 to 1%. And enter the mold cavity through the feeding pipe, and then it will be continuously tightened under the action of the hydraulic pressure head, and the pressure will stop when the pressure reaches 300±15MPa. At this time, the temperature control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com