A kind of active coating solution for chlorine analysis electrode and preparation method thereof

A chlorine-evolution electrode and active technology, applied in the field of active coating solution and its preparation, can solve the problems of low chlorine-evolution efficiency, high operation cost, secondary pollution and the like of sodium hypochlorite generator electrode, achieve good synergistic catalysis effect and reduce operation cost , the effect of increasing the efficiency of chlorine evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

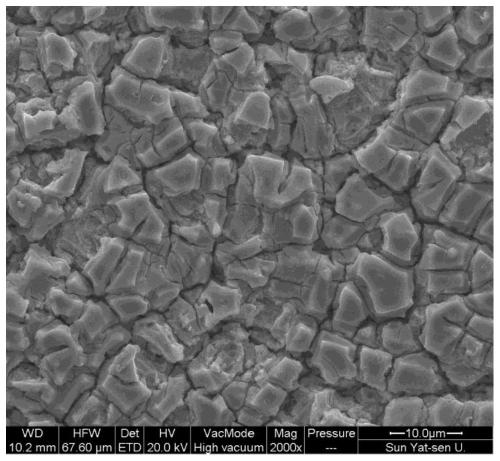

Image

Examples

preparation example Construction

[0029] A kind of preparation method for the active coating solution of chlorine analysis electrode, comprises the following steps:

[0030] 1) Prepare the raw materials required for the solvent, solute and stabilizer, and prepare the solvent and solute according to the proportion for subsequent use;

[0031] 2) Add the solute to the solvent in turn, after fully dissolving, pour the stabilizer into it, and mix evenly.

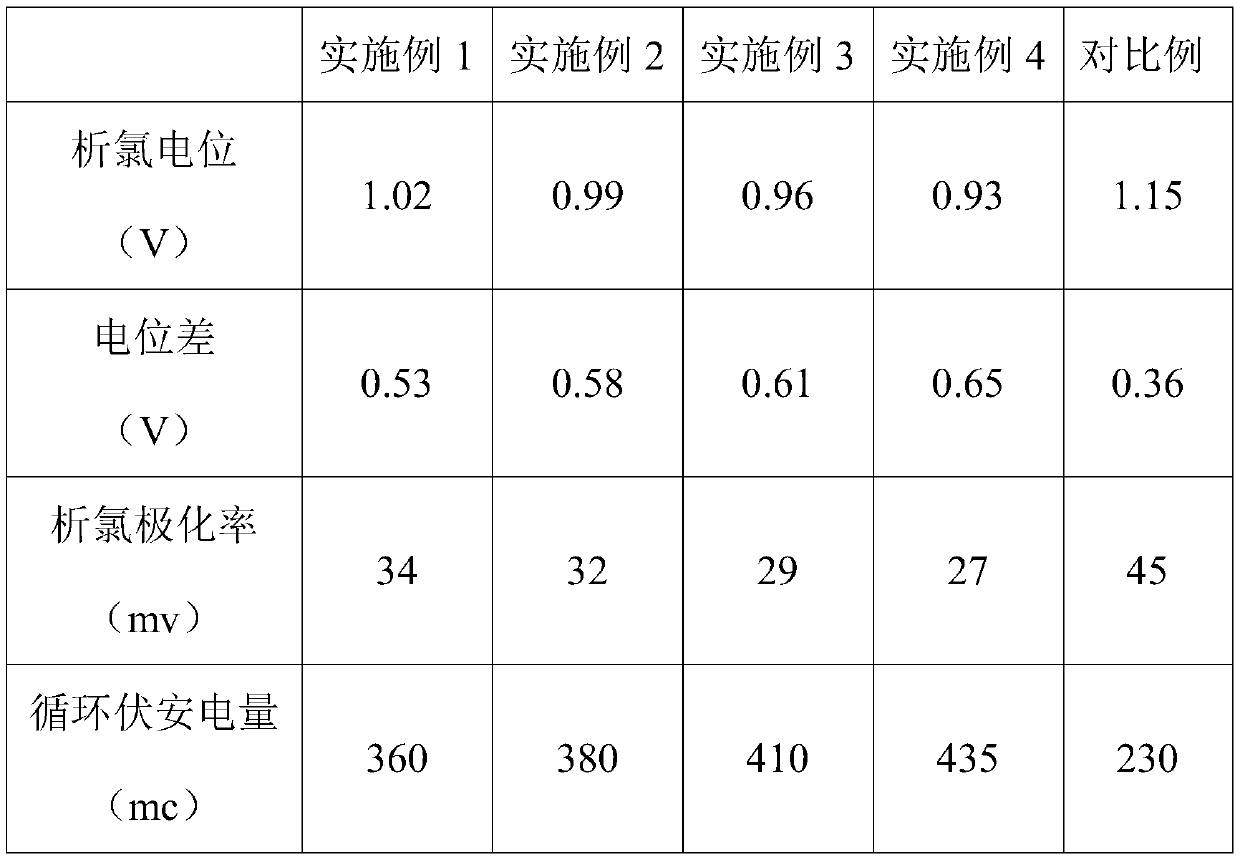

Embodiment 1

[0033] An active coating solution for chlorine analysis electrodes, including solvent, solute and stabilizer; solvent is composed of n-butanol and isopropanol, and the mass ratio of n-butanol and isopropanol is 2:1; stabilizer is concentrated Hydrochloric acid; solute is made up of ruthenium trichloride, chloroiridic acid, tetrabutyl titanate and chlorine analysis accelerator, and chlorine analysis accelerator is made up of neodymium chloride, europium nitrate; the metal ion concentration in active coating liquid is 0.3mol / L, the volume ratio of solvent to stabilizer is 10:1.

[0034] In the active coating solution, Ru 4+ The proportion of metal ions in the solution is 17mol%, Ir 4+ The proportion of metal ions in the solution is 9mol%, Ti 4+ The proportion of metal ions in the solution is 72mol%, and the proportion of metal ions in the solution occupied by the chlorine analysis accelerator is 2mol%; in the chlorine analysis accelerator, Nd 3+ 、Eu 3+ The molar ratio is 3:...

Embodiment 2

[0036] An active coating solution for chlorine analysis electrodes, including solvent, solute and stabilizer; solvent is composed of n-butanol and isopropanol, and the mass ratio of n-butanol and isopropanol is 2:1; stabilizer is concentrated Hydrochloric acid; solute is made up of ruthenium trichloride, chloroiridic acid, tetrabutyl titanate and chlorine analysis accelerator, and chlorine analysis accelerator is made up of europium chloride, ytterbium sulfate; The metal ion concentration in active coating solution is 0.35mol / L, the volume ratio of solvent to stabilizer is 10:1.

[0037] In the active coating solution, Ru 4+ The proportion of metal ions in the solution is 19mol%, Ir 4+ The proportion of metal ions in the solution is 11mol%, Ti 4+ The proportion of metal ions in the solution is 68mol%, and the proportion of metal ions in the solution occupied by the chlorine analysis accelerator is 2mol%; Eu in the chlorine analysis accelerator 3+ , Yb 3+ The molar ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com